Small sample dyeing bracket for filament/yarn laboratory

A laboratory and yarn technology, applied in the field of dyeing stents, can solve the problem that the inner filaments or yarns are difficult to dye and dye, the inner filaments or yarns are not easy to infiltrate and dye, and the filaments or yarns are entangled with each other. and other problems, to achieve the effect of leveling effect and mutual entanglement, reducing mutual entanglement and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

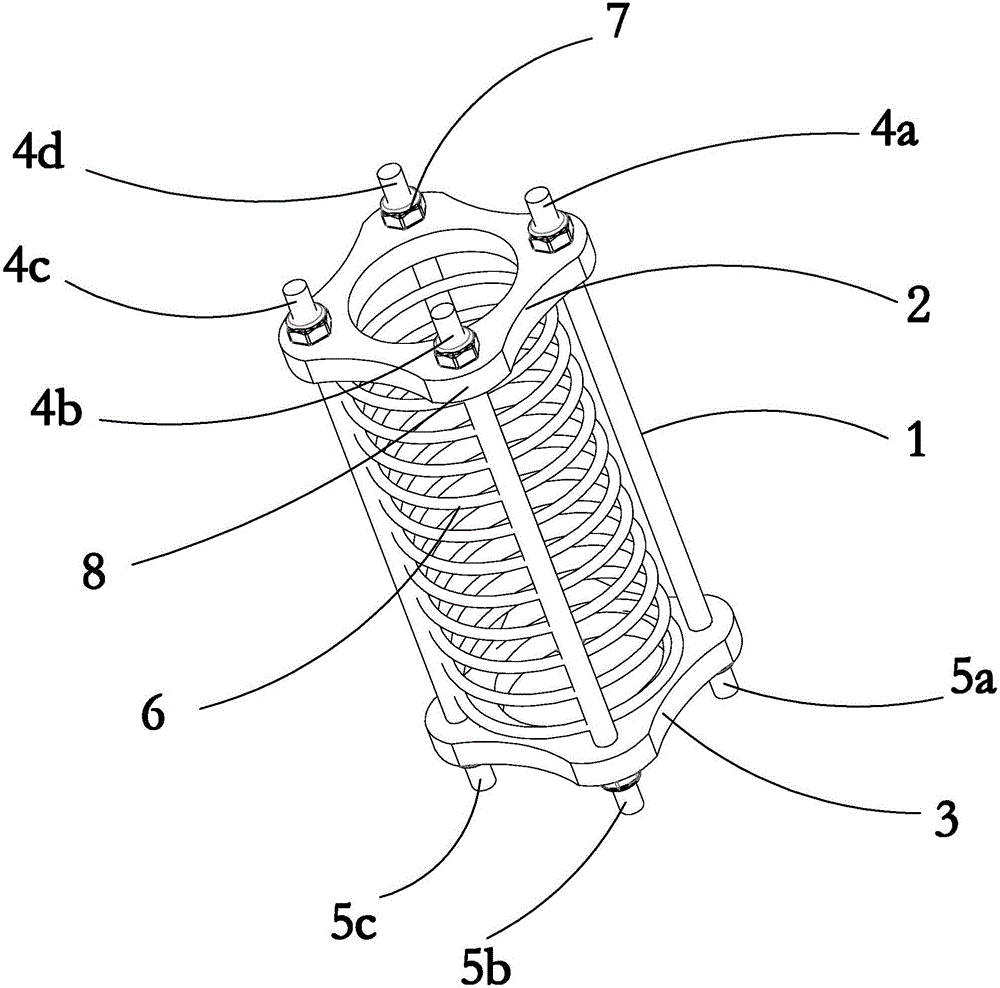

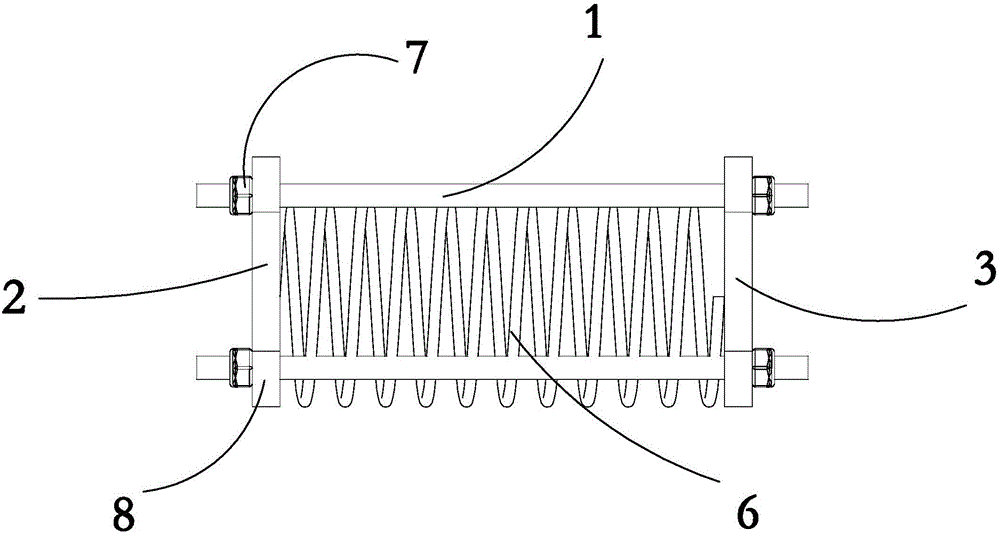

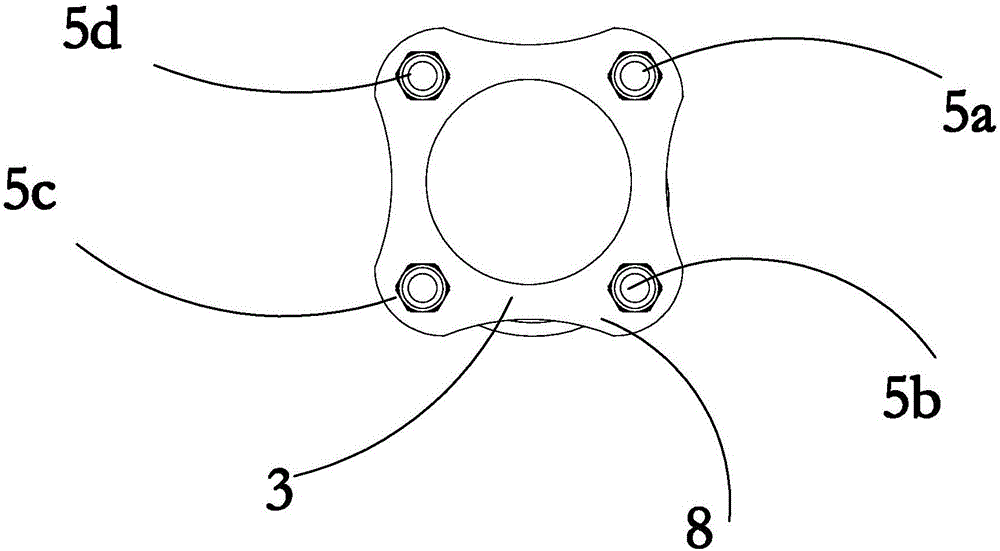

[0015] The invention is mainly applied to the dyeing support of filaments or yarns in laboratory samples. figure 1 , figure 2 The shown preferred embodiment filament or yarn laboratory small sample dyeing support includes a support assembly, and the support assembly includes at least one support column 1, a first support plate 2 and a second support plate 3 with a fixed or adjustable spacing, The support column 1 is connected to the first support plate 2 and the second support plate 3, and the outer periphery of the first support plate 2 is distributed with four first winding columns 4a, 4b, 4c, 4d (4d such as image 3 As shown), four second winding posts 5a, 5b, 5c, 5d are distributed on the outer periphery of the second support plate 3 . The four first winding posts 4a, 4b, 4c, 4d are evenly distributed along the edge of the first support plate 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com