Silk thread printing and coloring device

A silk thread, a pair of technology, applied in the field of silk thread printing and coloring devices, can solve the problems of occupying the production space of the manufacturer, increasing the labor intensity, and increasing the production capital of the manufacturer, and achieves the effect of simple operation, convenient coloring, and reduced production capital.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

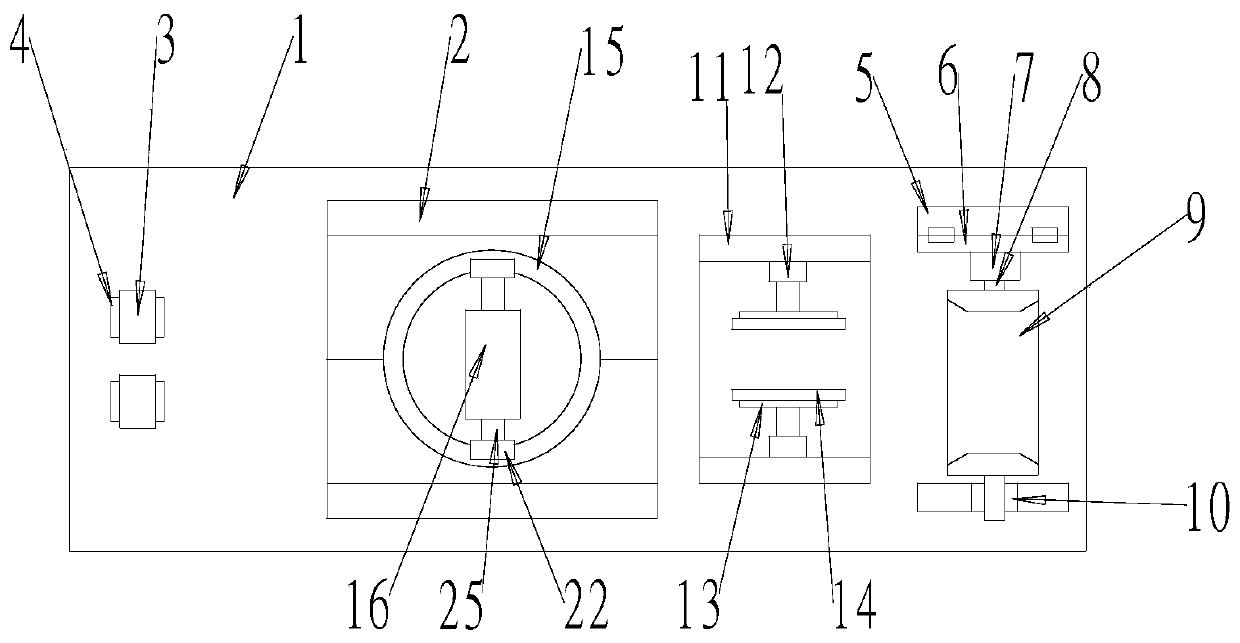

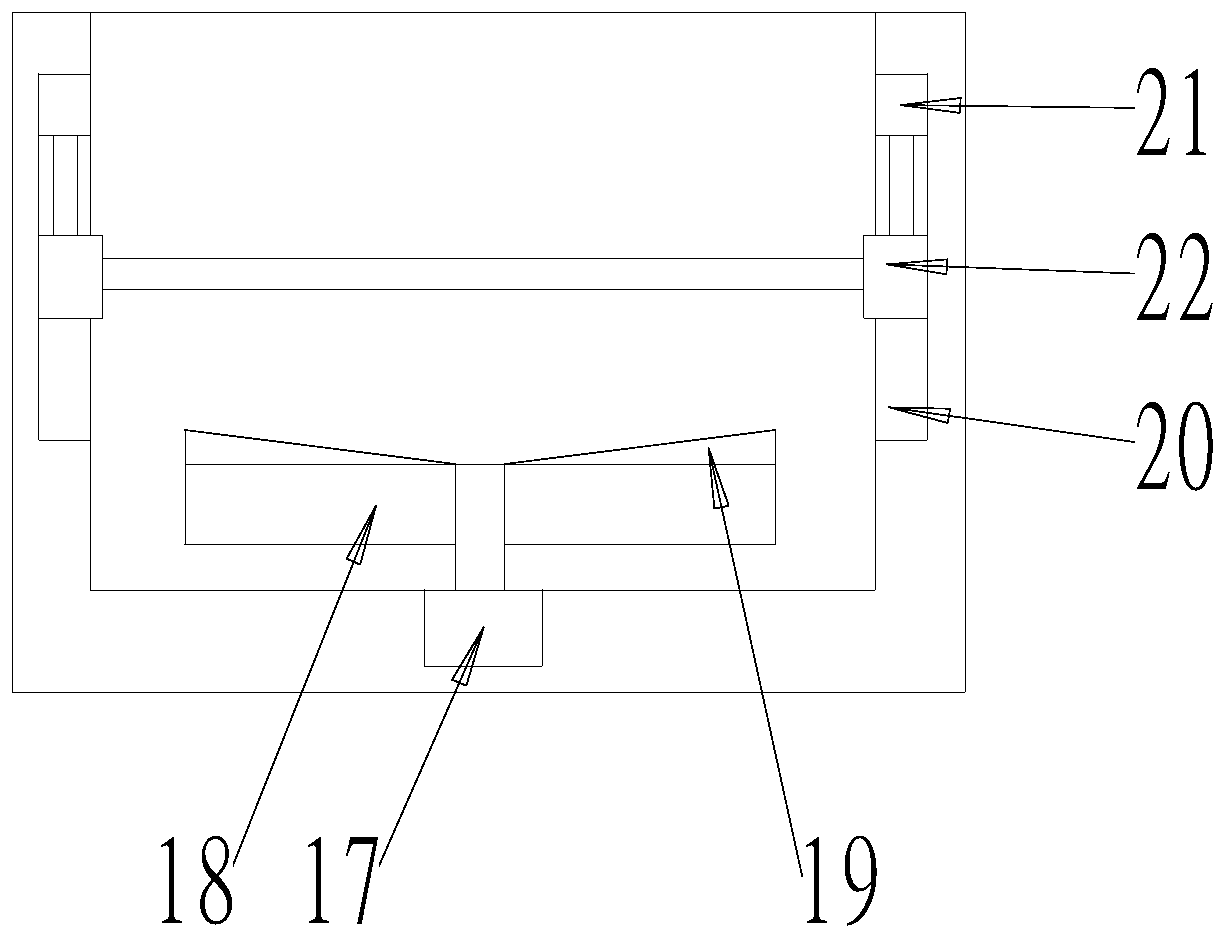

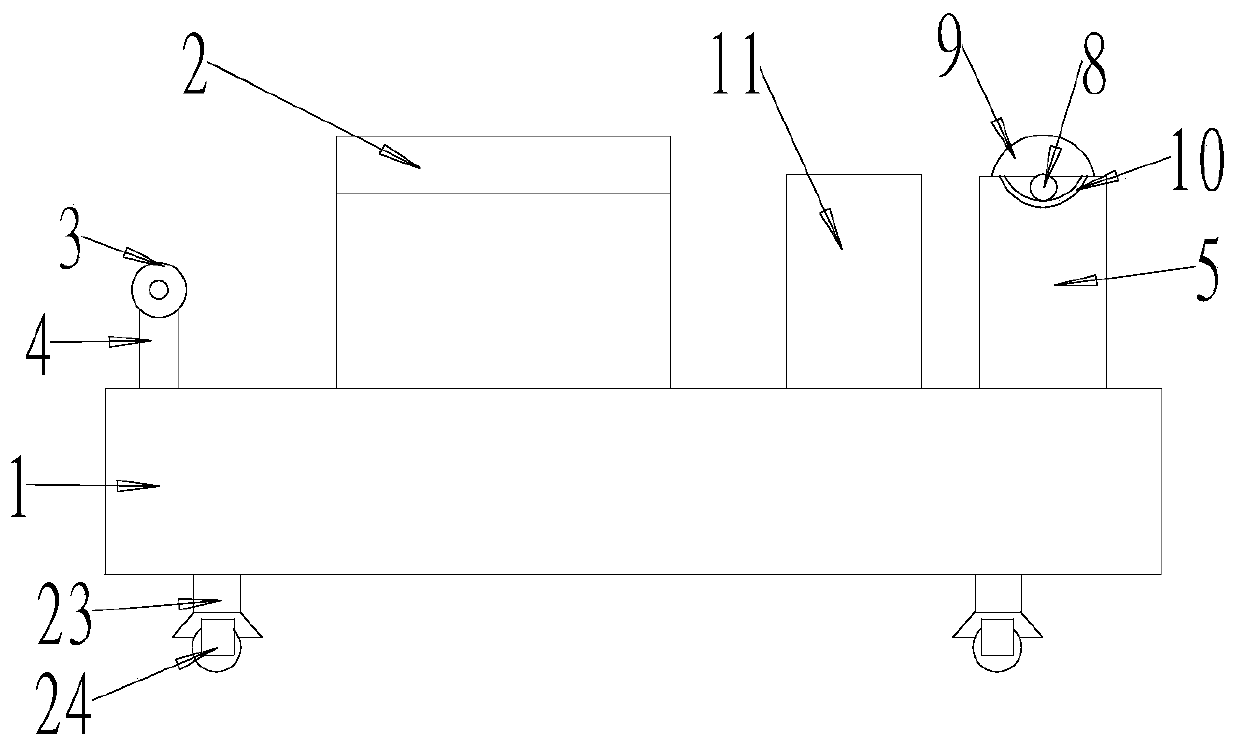

[0030] First, the installation console 1 is moved through the universal wheel 23. When moving to the designated work place, the universal wheel 23 can be restricted and fixed by the brake pad 24, so as to avoid shaking during work, and then the silk thread passes through the first The second roller 3 enters the first roller 16, and then the lifting part on the first roller will drive the silk thread to go up and down, so as to achieve the effect of dyeing. The linear motor 12 on the lifting part drives the slider 22 to extend downward in the strip slideway 20 , so that the first roller 16 drives the silk thread to touch the liquid, and then in order to prevent the liquid from solidifying, the stirring plate 19 on the rotating disk 18 can be driven by the second rotating motor 17 to rotate, and the liquid will be stirred to avoid solidification, and then dyed When finished, the miniature linear cylinder 21 drives the push plate 13 to expand and contract, so that the replaceable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com