Opening structure of side plate of milling machine, side plate and milling machine

A milling machine and side plate technology, applied in the field of road surface engineering equipment, can solve the problems of heavy workload, difficult removal process of supporting flange screws, and long time consumption, so as to improve the replacement efficiency and reduce the possibility of interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

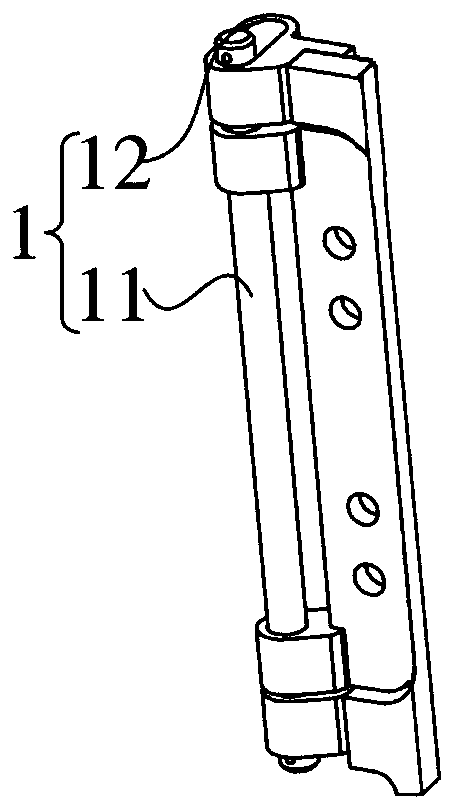

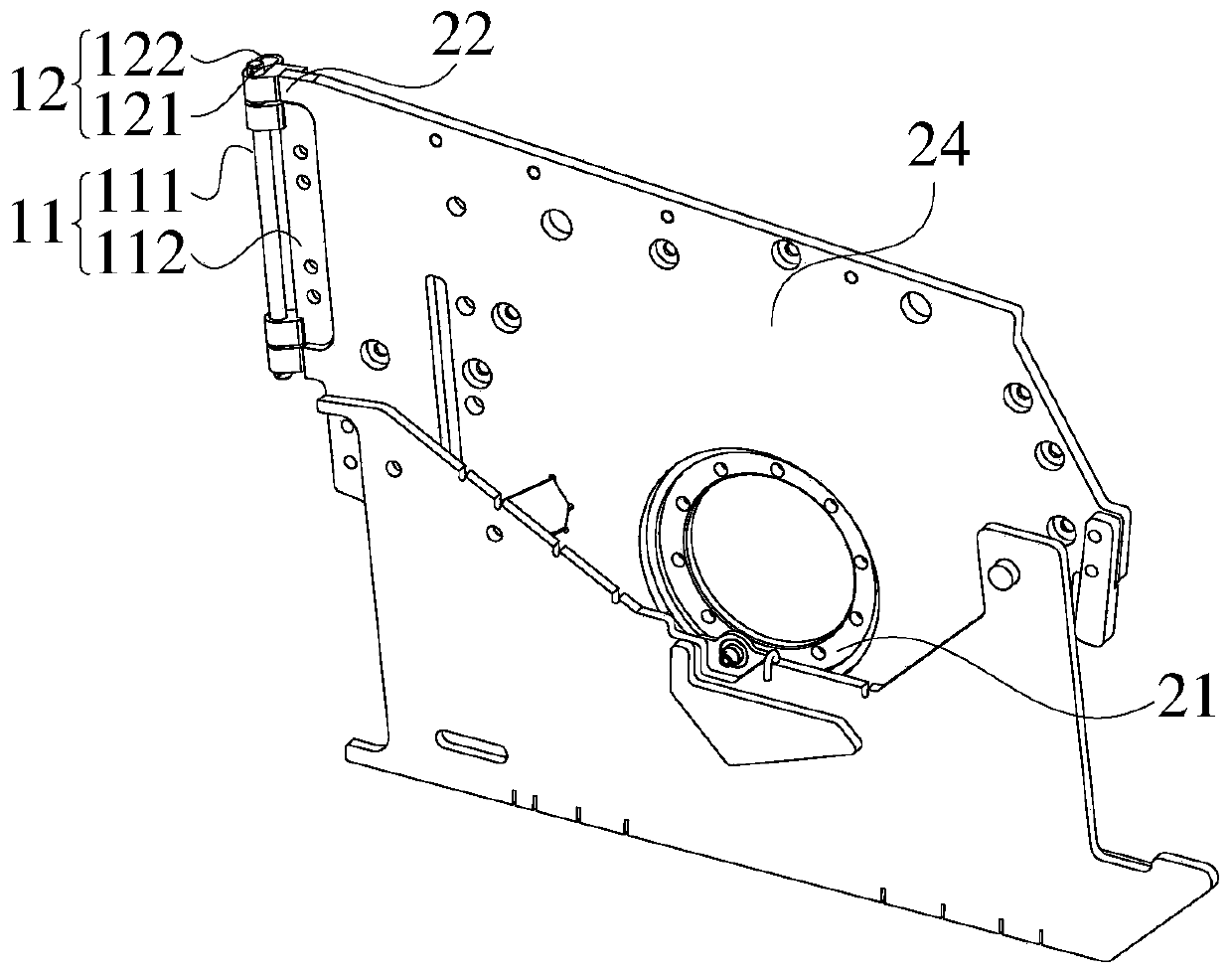

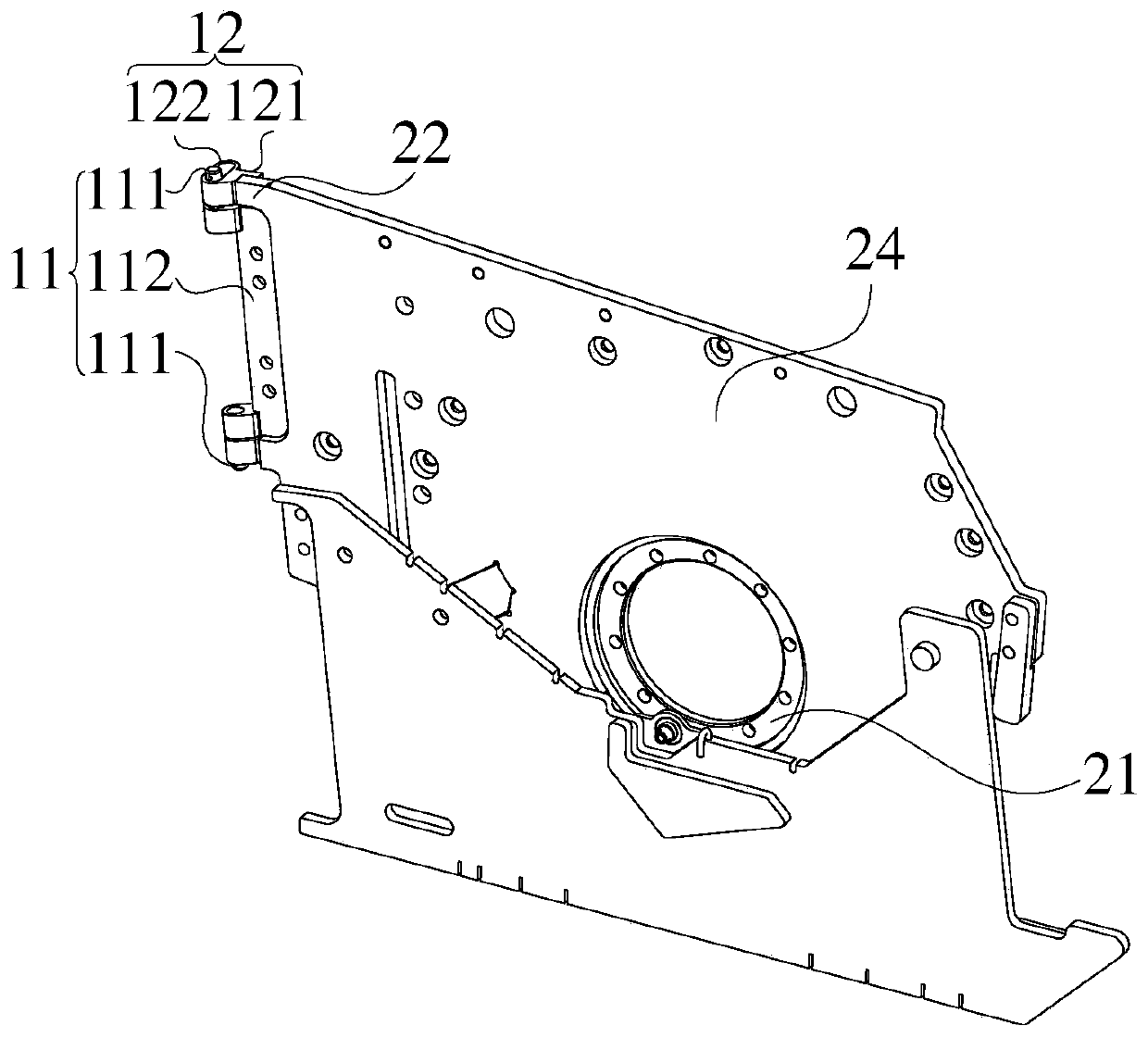

[0043] Specifically, as figure 1 As shown, the opening structure 1 includes a connected sliding member 12 and a rotating member 11, wherein the rotating member 11 can perform a translational movement relative to the sliding member 12, so that the two parts connected to the sliding member 12 and the rotating member 11 respectively, For example, the side plate 2 and the milling machine body 3 can be relatively translated and rotated.

[0044] When the milling drum is arranged in the milling machine, the side plate 2 is provided with a support flange 21, and the support flange 21 abuts against the bearing support 41 of the milling drum, the rotating part 11 is used to make the side plate 2 relatively The milling drum rotates; a part of the rotating part 11 is arranged in the sliding part 12, so that the side plate 2 can translate along the axial direction of the bearing support 41, so as to be away from or close to the milling drum; the sliding part 12 is provided with a Connect...

Embodiment 2

[0047] On the basis of Embodiment 1, further, the rotating member 11 includes a cylindrical part, and the sliding part 12 includes a long strip-shaped part suitable for the cylindrical part, and one axial end of the cylindrical part is loosely fitted with the long strip-shaped part , so that the cylindrical part can translate along the length direction of the elongated part, and enable the elongated part to make a circular motion around the axis of the cylindrical part.

[0048] Specifically, the rotating part 11 is provided with a position for the relative rotation of the sliding part 12, and by setting the part on the rotating part 11 for connecting with the sliding part 12 into a cylindrical shape, the rotation of the sliding part 12 can be more convenient, thereby facilitating The opening process of side plate 2 on the rotation mode. Similarly, the sliding part 12 is provided with a position for the relative sliding of the rotating part 11, and by setting the part on the s...

Embodiment 3

[0052] On the basis of embodiment one or embodiment two, further, as figure 1 As shown, the slider 12 includes a connecting portion 121, which is used to connect the side plate 2 or the milling machine body 3, and makes the extending direction of the elongated part perpendicular to the plane where the side plate 2 is located.

[0053] By setting the connecting part 121, the connecting part 121 for installing with the side plate 2 or the milling machine body 3 is provided for the sliding part 12 on the one hand, which facilitates the installation of the sliding part 12; The positional relationship between the guide groove and the side plate 2 helps to limit the opening route of the side plate 2 in the translational movement, making the opening more convenient and reducing the support flange 21 on the side plate 2 and the bearing support 41 of the milling machine possibility of interference.

[0054] Further, the connecting portion 121 is provided with a stepped surface, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com