Helicopter with transverse duct

A helicopter and horizontal technology, applied in the field of helicopters, to improve the design, reduce production and maintenance costs, and improve the impression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

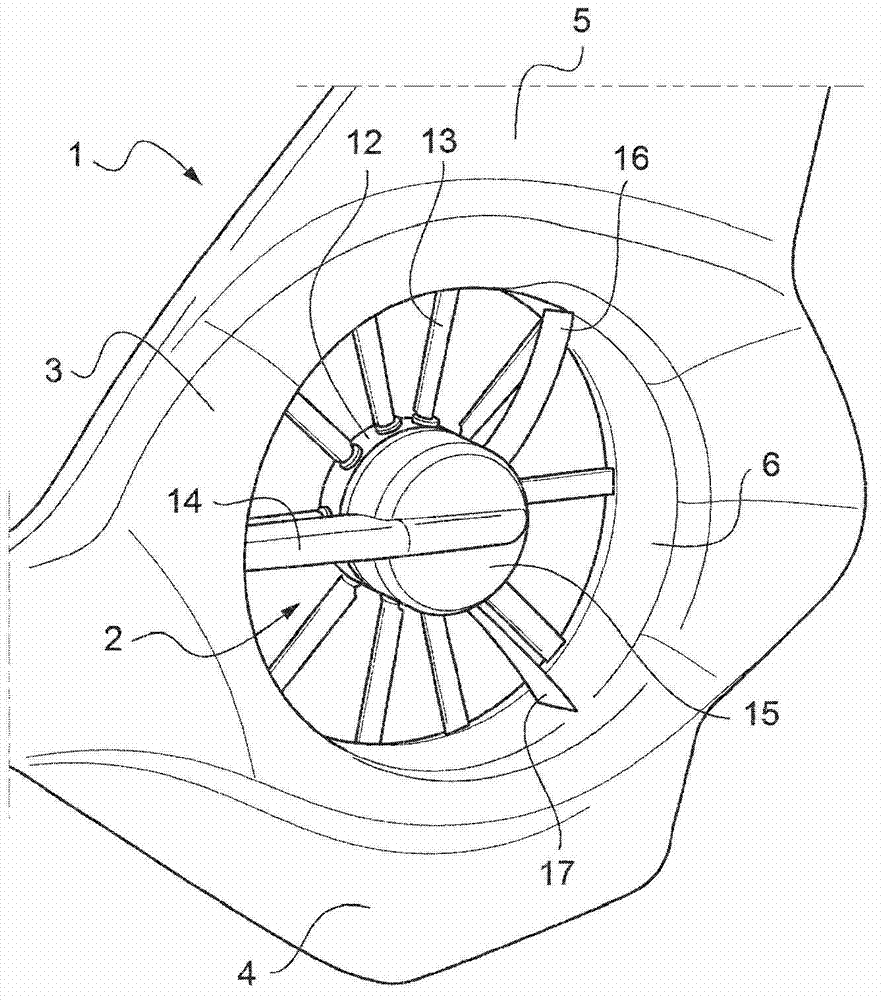

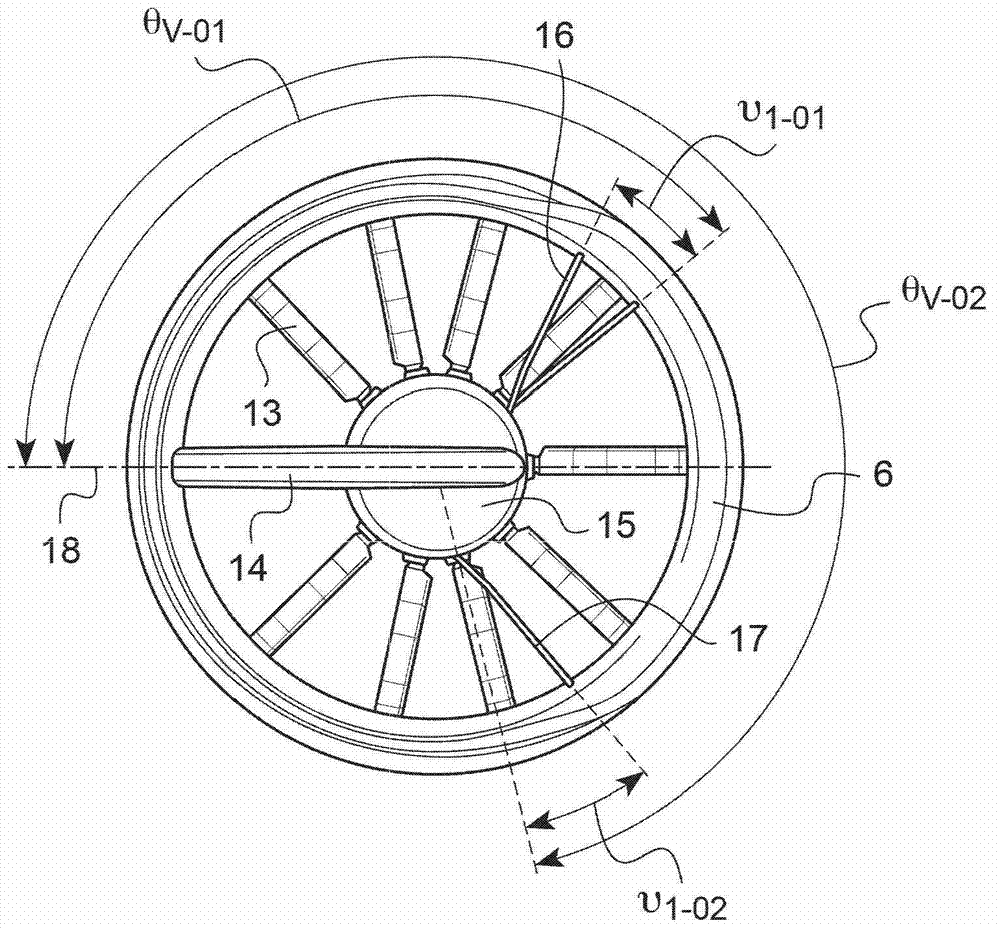

[0030] figure 1 A transverse ducted tail 1 of a helicopter (not shown) is shown. The transverse ducted tail 1 includes a cover 3 , a buffer 4 and a wing 5 . The transverse ducted tail 1 also includes an anti-torque device 2 configured to resist the torque generated by the rotation of the main rotor of the helicopter, so as to keep the helicopter in balance when yawing. The anti-torque device 2 is supported in a transverse duct 6 which extends through the cover 3 of the tail section 1 .

[0031] The transverse duct 6 is substantially circular and comprises a rotor, a rotor plane being defined by rotor blades 13 . Air flows through the transverse ducts 6 of the anti-torque device 2 .

[0032] The anti-torque device 2 comprises a stator with stator blades 16 , 17 , a drive shaft fairing 14 and a gearbox fairing 15 .

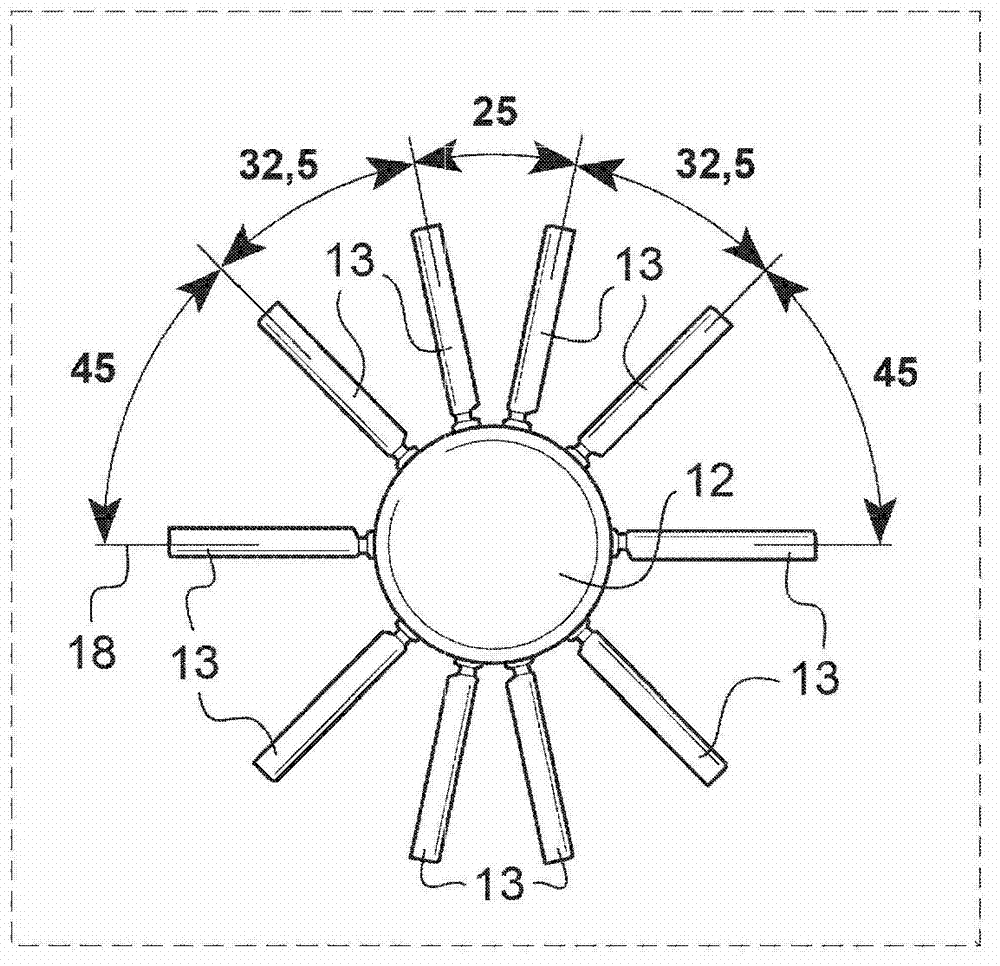

[0033] Ten rotor blades 13 are attached to a rotor hub 12 having a rotor axis. The ten rotor blades 13 are distributed on the rotor hub 12 at a non-uniform angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com