A sub-board plug assembly and an inter-board connection assembly

A technology for plug assemblies and seed boards, which is applied in the installation of connecting components, components of connecting devices, connections, etc., can solve the problems of reliability impact, potential safety hazards, unreliable locking of daughter board plug assemblies and backplane socket assemblies, etc. , to achieve the effect of simple setup and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following is attached with the manual Figure 1 to Figure 10 The inter-board connection assembly of the present invention will be further described.

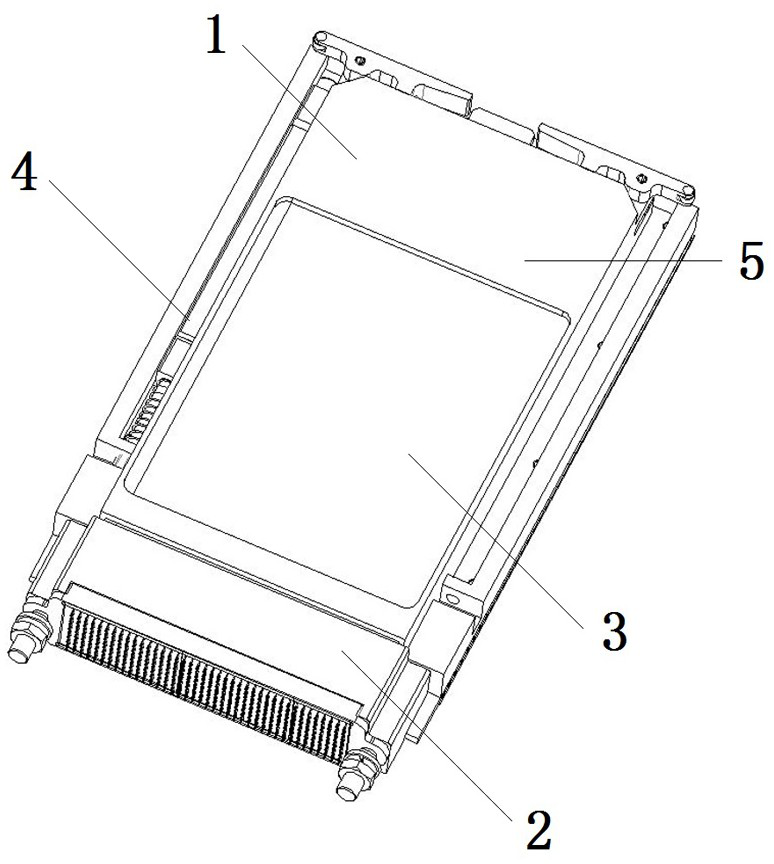

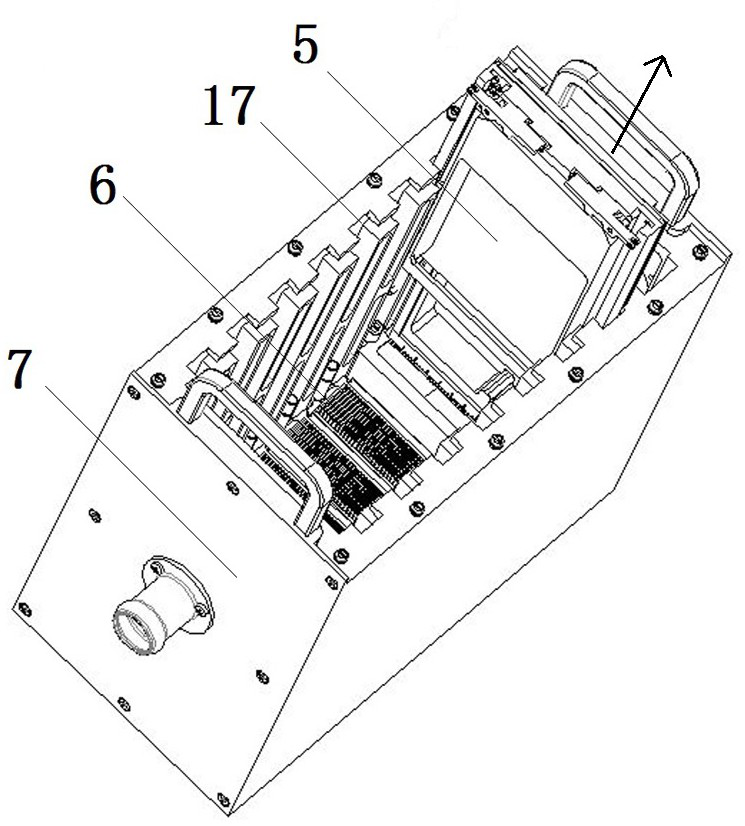

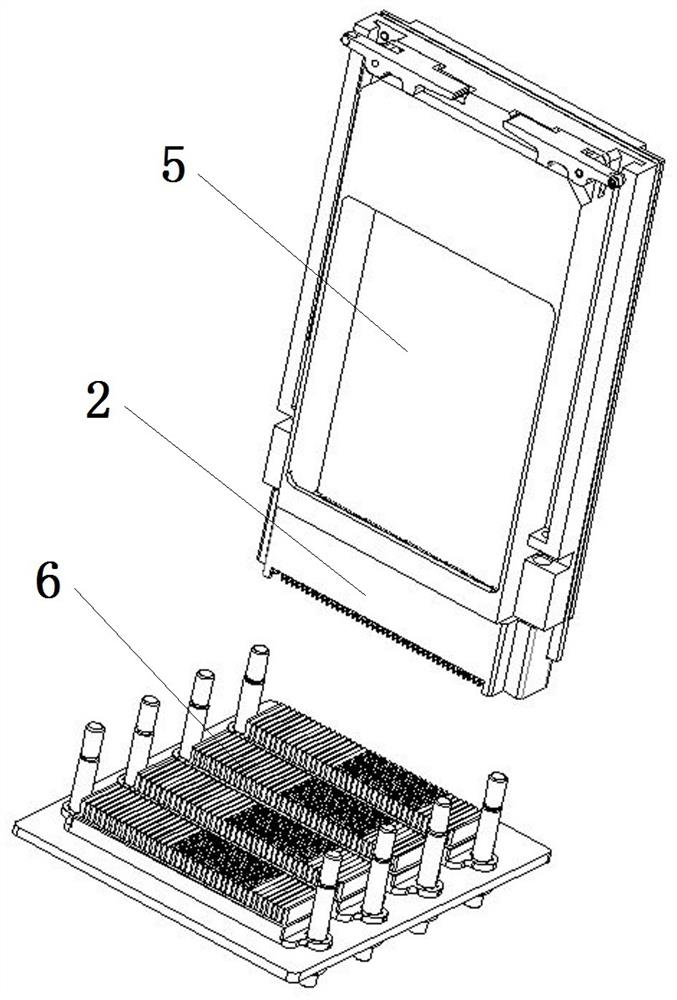

[0065] Such as Figure 1 to Figure 4 As shown, the inter-board connection assembly of the present invention includes a sub-board plug assembly 5 and a backplane socket assembly 6, and the backplane socket assembly 6 is fixedly installed in the cabinet 7, and a guide groove 17 is provided on the inner wall of the cabinet, and the sub-board plug The assembly 5 can be inserted into the chassis along the guide groove 17 and plugged with the backplane socket assembly 6, and the sub-board plug assembly 5 can be inserted according to figure 2 The direction shown by the arrow in the center is pulled out from the chassis 7. The sub-board plug assembly 5 also includes a sub-board fixing frame 1 for installing the sub-board 3. The sub-board fixing frame 1 is a rectangular frame structure. The front end of 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com