Packaging product processing glue rolling device

A packaging product and glue rolling technology, which is applied in the direction of the surface coating liquid device, coating, etc., can solve the problems of easy glue sticking, uneven application, unfavorable processing and use of packaging products, etc., so as to save the cleaning process, The effect of rapid processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

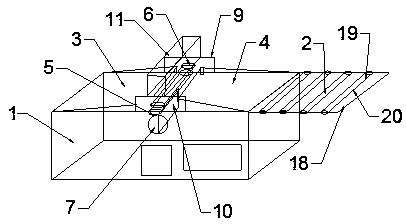

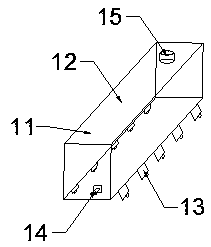

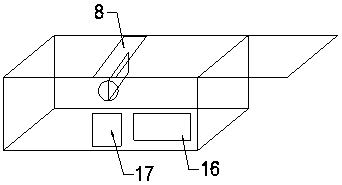

[0014] Such as Figure 1 to Figure 3 As shown, the present invention is a rubber rolling equipment for processing packaging products, including a main body frame 1, an auxiliary unloading roller 2, a material lifting plate 3, a material lifting plate 4, a driving rubber roller 5, and a driven rubber roller 6 and the power motor 7, the inner surface of the body frame 1 is fixedly connected with the power motor 7, and the upper surface of the body frame 1 is provided with a grooved long hole 8, and the two sides of the grooved long hole 8 in the length direction are respectively The active rubber roller 5 is fixedly connected with the bearing, the one side surface of the body frame 1 in the width direction is fixedly connected with a fixed support plate I9, and the other side surface of the body frame 1 in the width direction is fixed with a support plate II10, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com