Switch cabinet manufacturing device and switch cabinet manufactured through device

A technology for preparing devices and switch cabinets, which is applied in the cooling/ventilation of substation/switchgear, details of substation/switch arrangement, feeding device, etc., and can solve the problem of no buffer device, metal plate position offset, and no metal plate Issues such as limits and fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

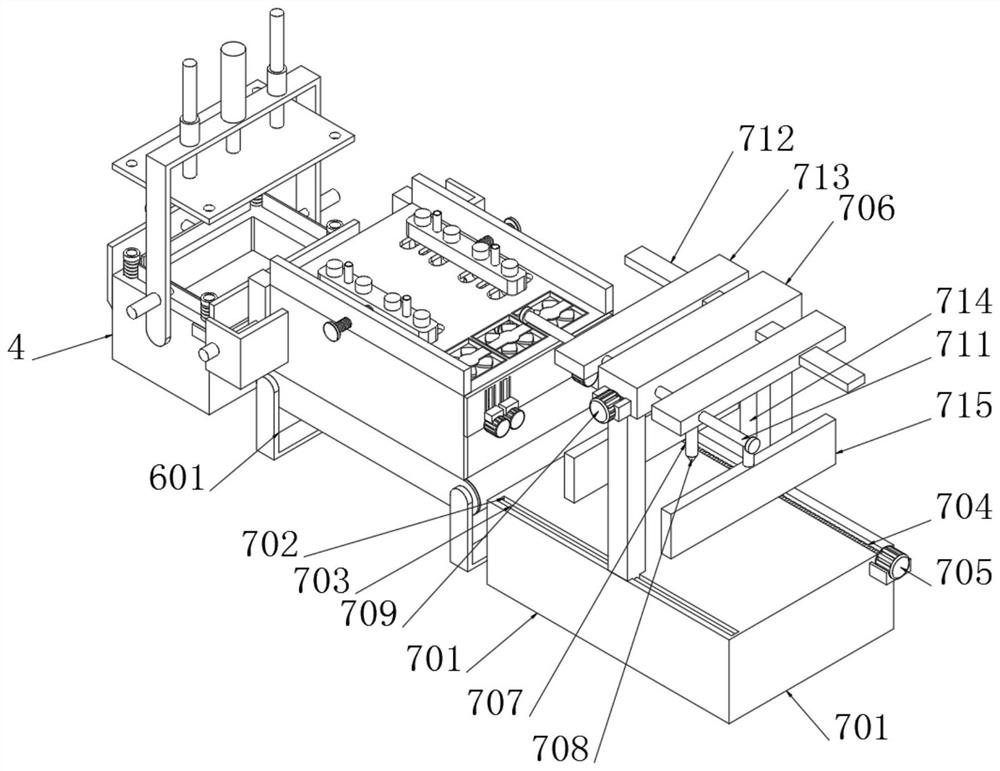

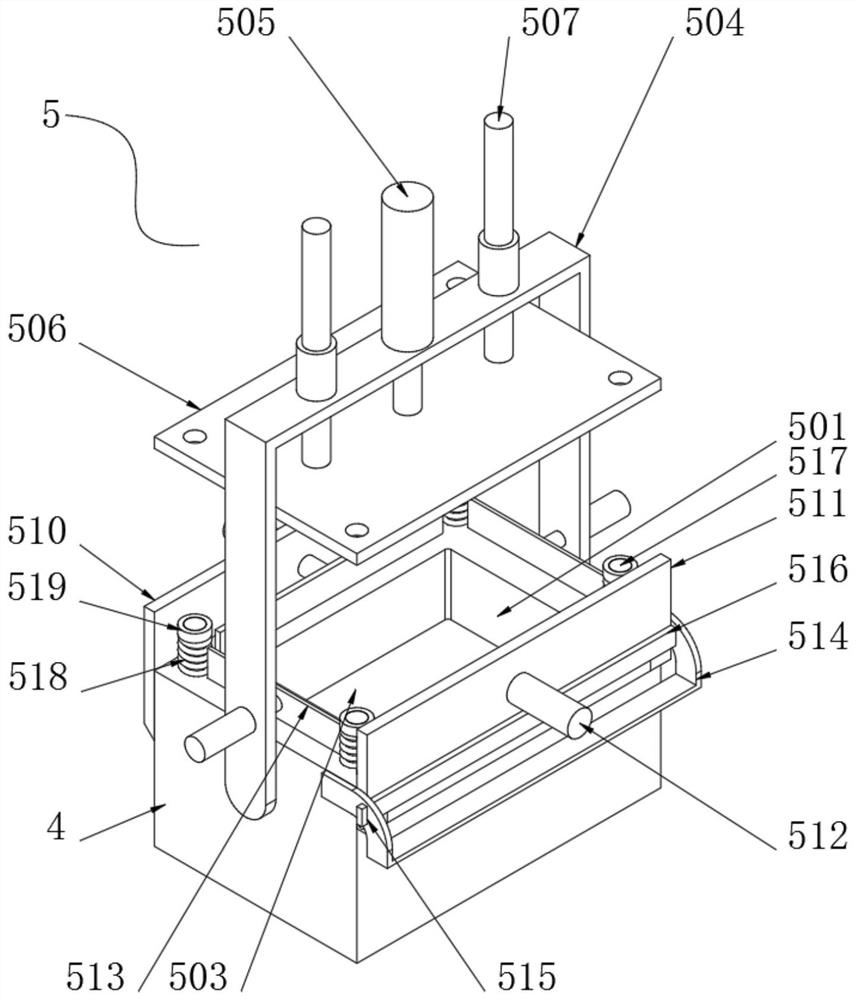

[0063]Example 1: Such asFigure 1-7 As shown, the present invention provides a technical solution, a switchgear preparation device including a stamping die 4, a molded assembly 5 is mounted on the side of the stamped lower mold 4;

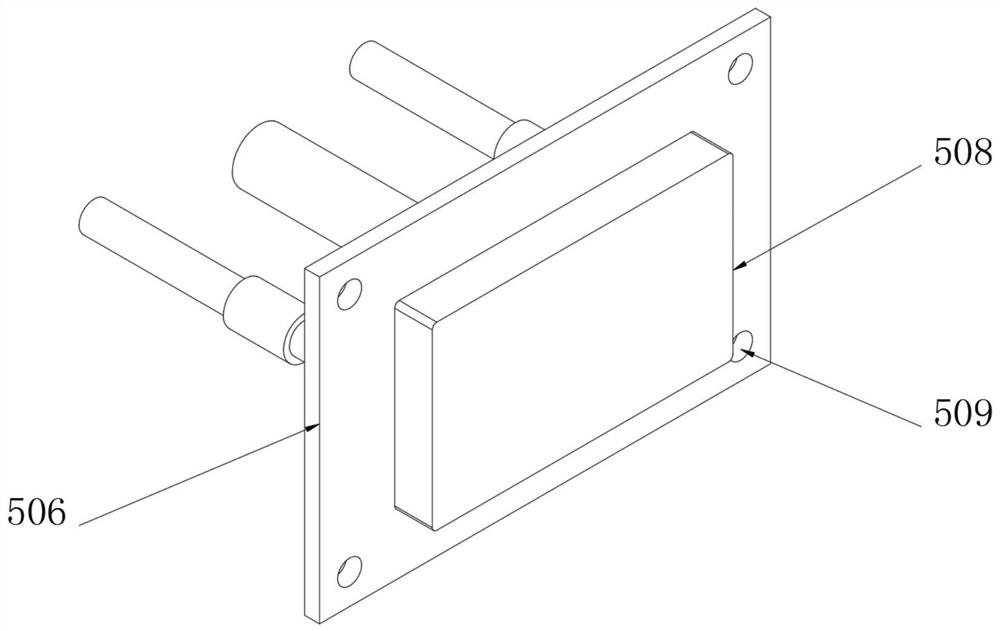

[0064]The forming assembly 5 includes a press cavity 501, a supporting hydraulic cylinder 502, a molded launch plate 503, a U-shaped support rod 504, a lower pressure hydraulic cylinder 505, a lower pressure molding plate 506, a guide connection rod 507, a lower pressure molded block 508, a guide hole 509, fixed mounting plate 510, rotating the mounting plate 511, clamping electric push rod 512, clamping plate 513, curved fixing frame 514, fixing hole 515, limit rod 516, guide post 517, cushion spring 518 and buffer pad 519;

[0065]The stamping cavity 501 is opened in the center of the stamper lower mold 4, and the stamping cavity 501 is sidedly fixedly mounted, and the support cylinder 502 is mounted. The top end of the support cylinder 502 is welded to the m...

Embodiment 2

[0077]Example 2: Such asFigure 8-13As shown, the present invention provides a technical solution, a switchgear, including a cabinet 1, a connecting assembly 2 on the cabinet 1;

[0078]The connecting assembly 2 includes a connection port 201, a slide 202, a slide groove 203, a sealing plate 204, a slide plate 205, a T-type fixing block 206, a connecting plate 207, an inverse port 208, a fixed connection block 209, and a rotating connection block 210, placement The cartridge 211, the support base 212, the fixed column 213, the cartridge 214, and the card 215;

[0079]The central portion of the cabinet 1 is sided there is a connection port 201, and the interior end of the cabinet 1 is located at the position of the connecting port 201, and the inner side of the cabinet 1 is located at both sides of the placement groove 202, and the slide groove 203 is opened. The inner side of the placing slot 202 is slidably mounted, and the sealing plate 204 is welded from one end of the placement groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com