A double external lead terminal coil and a winding method

A technology of double outer leads and lead terminals, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformer/inductor components, etc., can solve the problem of too many turns of wire and achieve high production efficiency , the effect of rapid processing and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

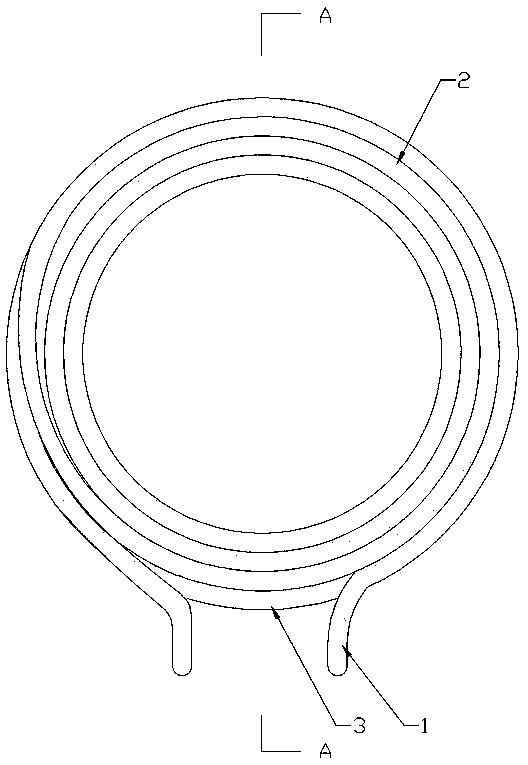

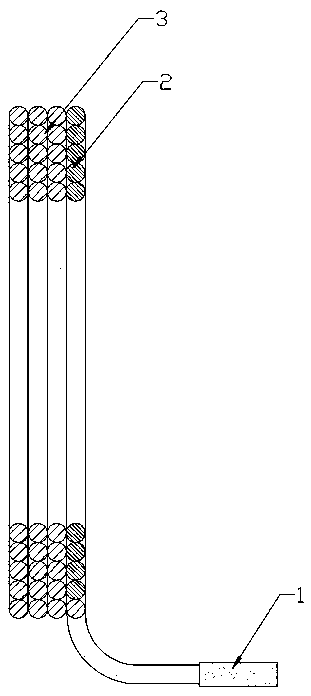

[0015] Reference attached Figure 1-2 , a double outer lead terminal coil, which is composed of M×N wire turns; both lead terminals 1 are located on the outermost layer at one end of the entire coil, and it is characterized in that the inner wire turns of the coil have the following structure Winding; the starting wire starts from the outermost layer on the side of the two lead terminals 1, and wraps a single wire M circles from outside to inside to the smallest wire circle to form the end bezel part 2, and then arranges layers horizontally and winds N-1 circles; The wire at the position of the N-1 lap wraps one lap and enters the M-1 layer. This layer is arranged in a total of N-1 laps and meets the end bezel part 2, and then laps and enters the M-2 layer. Reversely rewind again; reciprocate in this way until the first layer rewinds N-0.5 circles to reach the starting position of the end bezel part 2 to form the body bezel part 3;

[0016] The M is an even number greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com