Processing line and processing method for unlocking yoke springs

A technology for processing wires and jumping rods, which is applied in wire processing, wire manufacturing springs, and other household appliances to achieve the effects of improving processing efficiency, reducing burden, and reducing scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

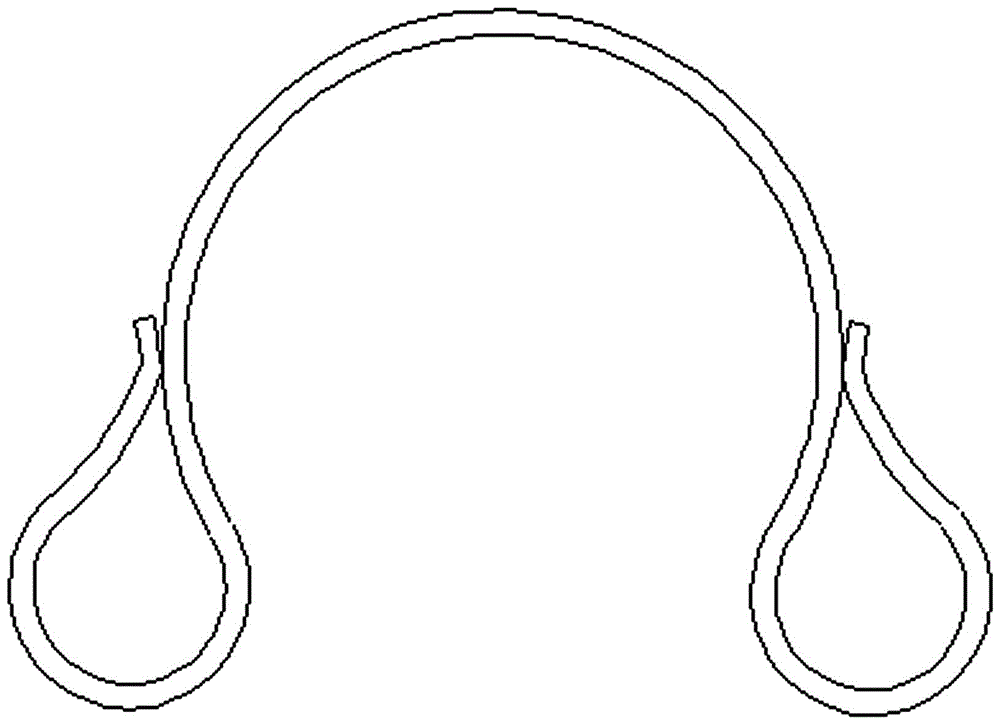

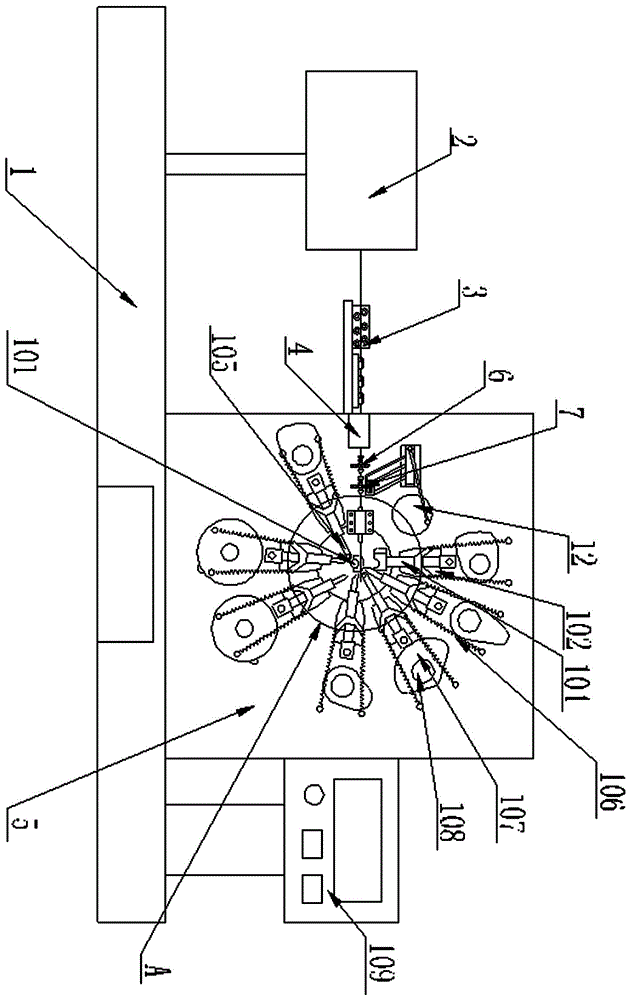

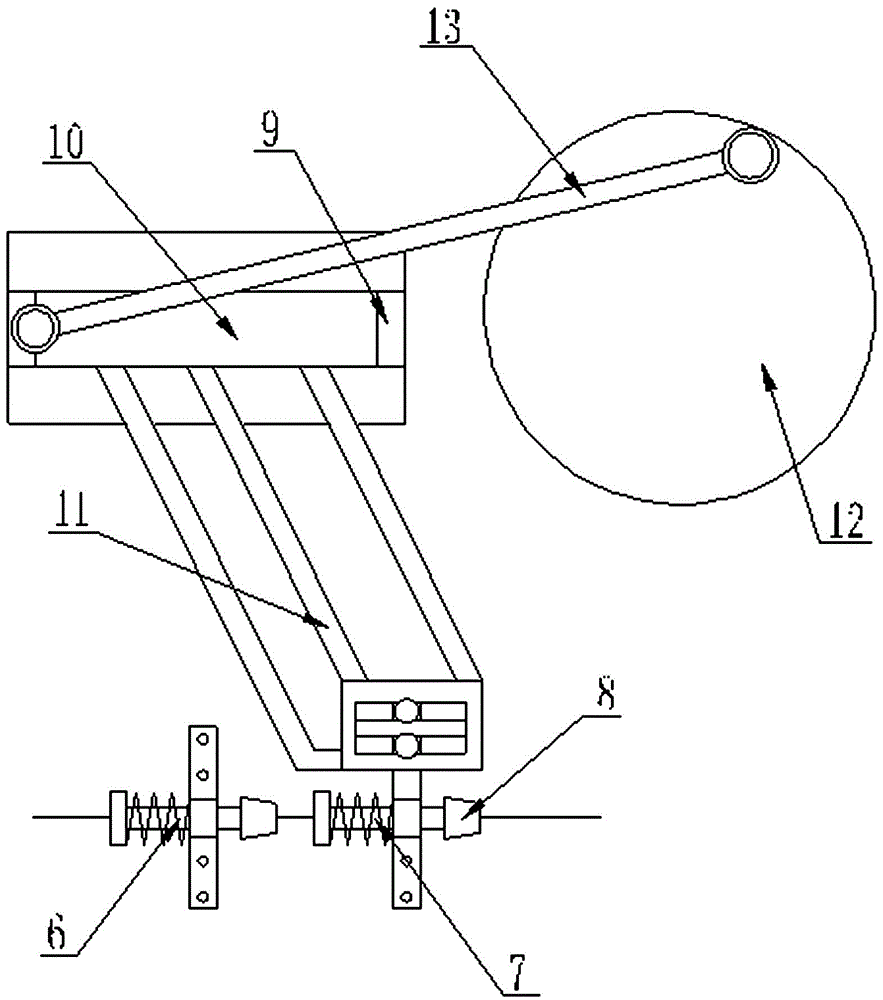

[0021] Embodiment one: if figure 1 As shown, a kind of jumper spring processing line according to the present invention includes a feeding mechanism, a lubricating mechanism and a processing mechanism, and the feeding mechanism includes a feeding tray 2 and a straightening wheel group 3 arranged on a support 1, and the feeding The raw material is wound on the disc 2, the straightening wheel set 3 includes at least two pairs of rollers with clearance fit, the middle part of the rollers is provided with an annular wire feeding groove, the lubrication mechanism includes a lubrication box 4 with a lubricant inside, and the side wall of the lubrication box 4 A through hole for the steel wire to pass is arranged on the top, and the feeding tray 2, the straightening wheel group 3 and the lubrication box 4 are arranged and arranged on the support 1 in sequence, and the steel wire enters the processing mechanism after being lubricated.

[0022] The processing mechanism includes a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com