Full-automatic equipment for inflating tubeless tire

A tubeless tire, fully automatic technology, applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc., can solve problems such as inflatable and tubeless tire deformation, reduce labor intensity, improve production efficiency, and simplify the inflation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

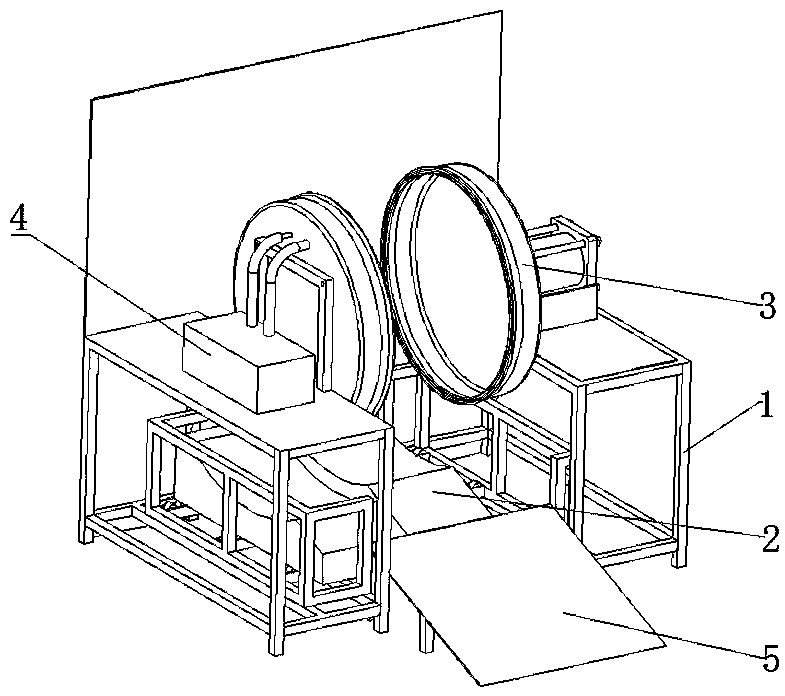

[0016] Such as figure 1 As shown, a fully automatic equipment for inflating a vacuum tire includes a support frame 1, a tire positioning device 2, an inflation device 3 and a control system 4 are arranged on the support frame, the tire positioning device is used to limit the tire, and the inflation device can The tubeless tire is axially clamped, and the inflation device can perform the detonation and inflation operations on the tubeless tire in sequence through the control system;

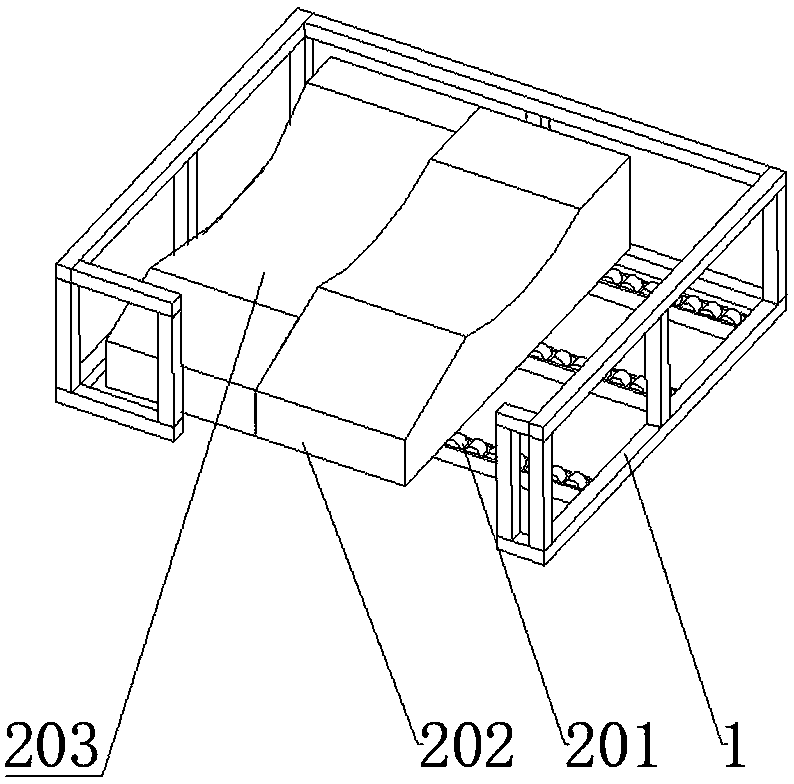

[0017] Such as figure 2 As shown, the tire positioning device 2 is composed of a nylon wheel guide rail 201 and a tire stop block 202, the nylon wheel guide rail is fixed on the support frame, the tire stop block is supported on the nylon wheel guide rail, and the supporting surface of the tire stop block Two positioning grooves 203 are provided, and the two positioning grooves are used for positioning tires of two diameters;

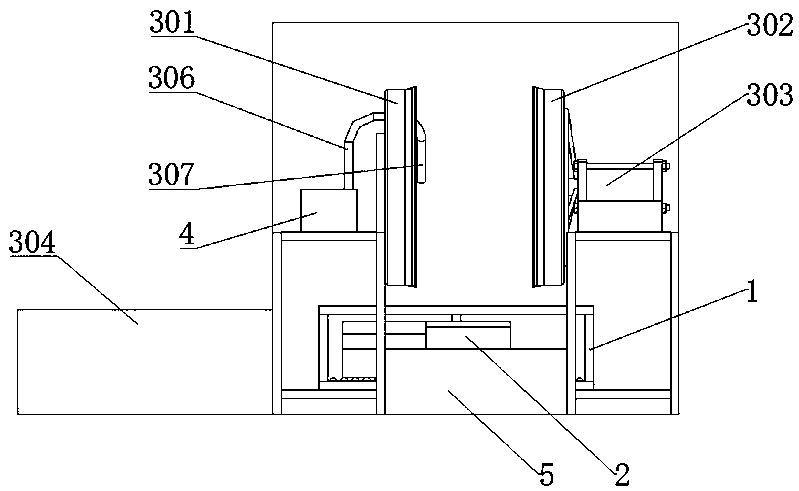

[0018] Such as image 3 with Figure 4 As shown, the inflation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com