A kind of air tightness detection method

An air-tightness detection and air-tightness technology, which is used in liquid/vacuum measurement for liquid tightness, and by detecting the appearance of fluid at the leak point, to improve detection efficiency, simplify the inflation process, and prevent leak detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

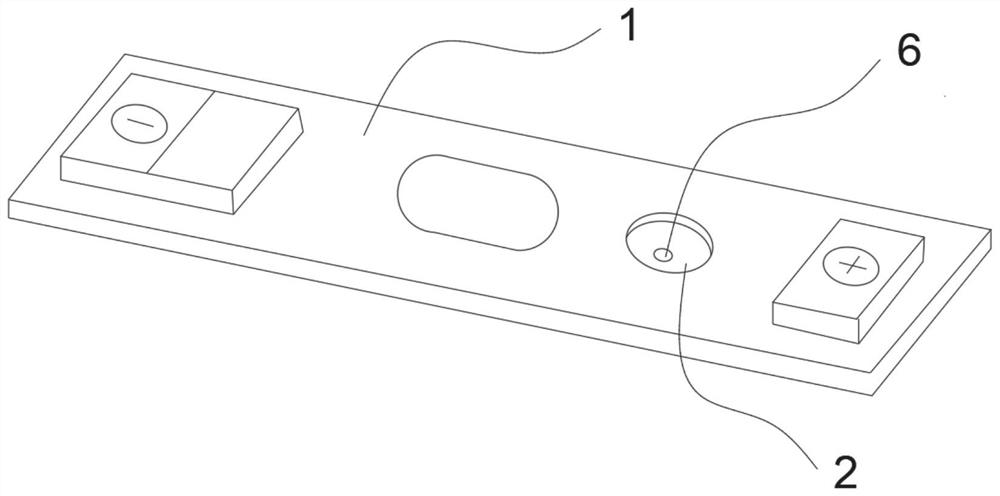

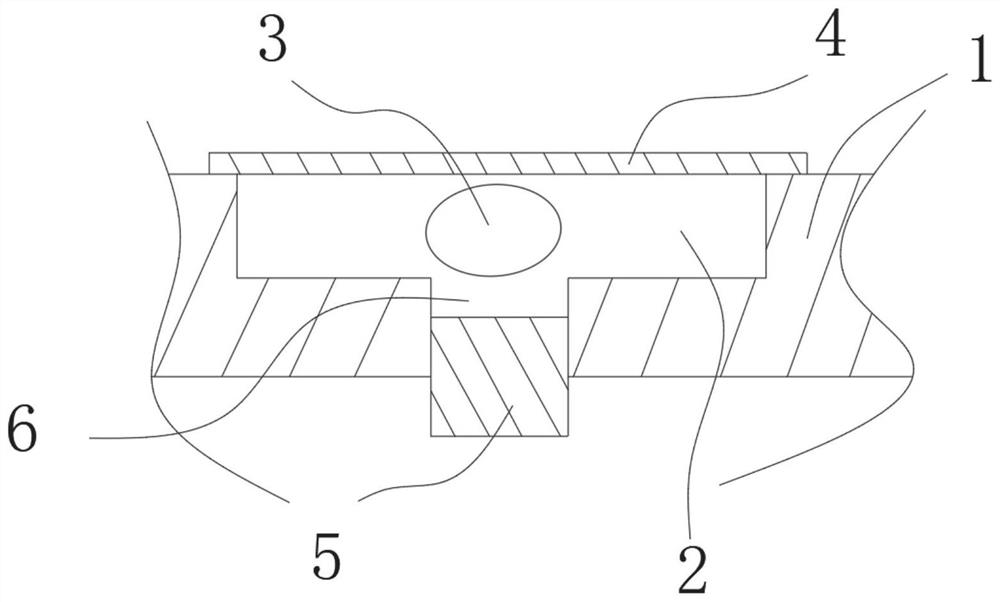

[0046] see figure 1 and figure 2, put the PP airbag 3 filled with helium into the liquid injection port 2 of the square lithium battery cover plate 1, the liquid injection hole 6 at the lower end is sealed with a rubber plug 5, and the upper end is sealed with an aluminum welding sheet 4, which is generated when the sealing is used. The heat of the airbag 3 is melted to release the helium, and then the square lithium battery cover 1 is detected in the special equipment to detect whether the helium exceeds the standard. If it is detected that the helium exceeds the standard, the airtightness of the welding seal is not good. If the excess helium is not detected, insert the rubber plug 5 with a needle to form a gap, vacuumize the square lithium battery cover plate 1 in a special device and check again whether there is excessive helium, if it is detected that the helium exceeds the standard, weld The airtightness of the seal is good. If the helium gas is not detected to exceed ...

Embodiment 2

[0048] see figure 1 with figure 2 Put the airbag 3 filled with helium into the liquid injection port 2 of the square lithium battery cover plate 1, the liquid injection hole 6 at the lower end is sealed with a rubber plug 5, and the airbag is crushed by using a repair welding piece 4 designed with an acute angle at the upper end 3. Then weld and seal, use the sharp angle to puncture the airbag and release the helium, and then put the square lithium battery cover 1 in the special equipment to detect whether there is excessive helium. If it is detected that the helium exceeds the standard, the airtightness of the welding seal is not good. If the excess helium is not detected, insert the rubber plug 5 with a needle to form a gap, vacuumize the square lithium battery cover plate 1 in a special device and check again whether there is excessive helium, if it is detected that the helium exceeds the standard, weld The airtightness of the seal is good. If the helium gas is not detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com