Method of depositing wet printed sheets and forming sheet stack

A sheet-stacking and sheet-sheet technology, applied in the graphics industry, printing and placement of sheets on the sheet stack, can solve problems such as irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

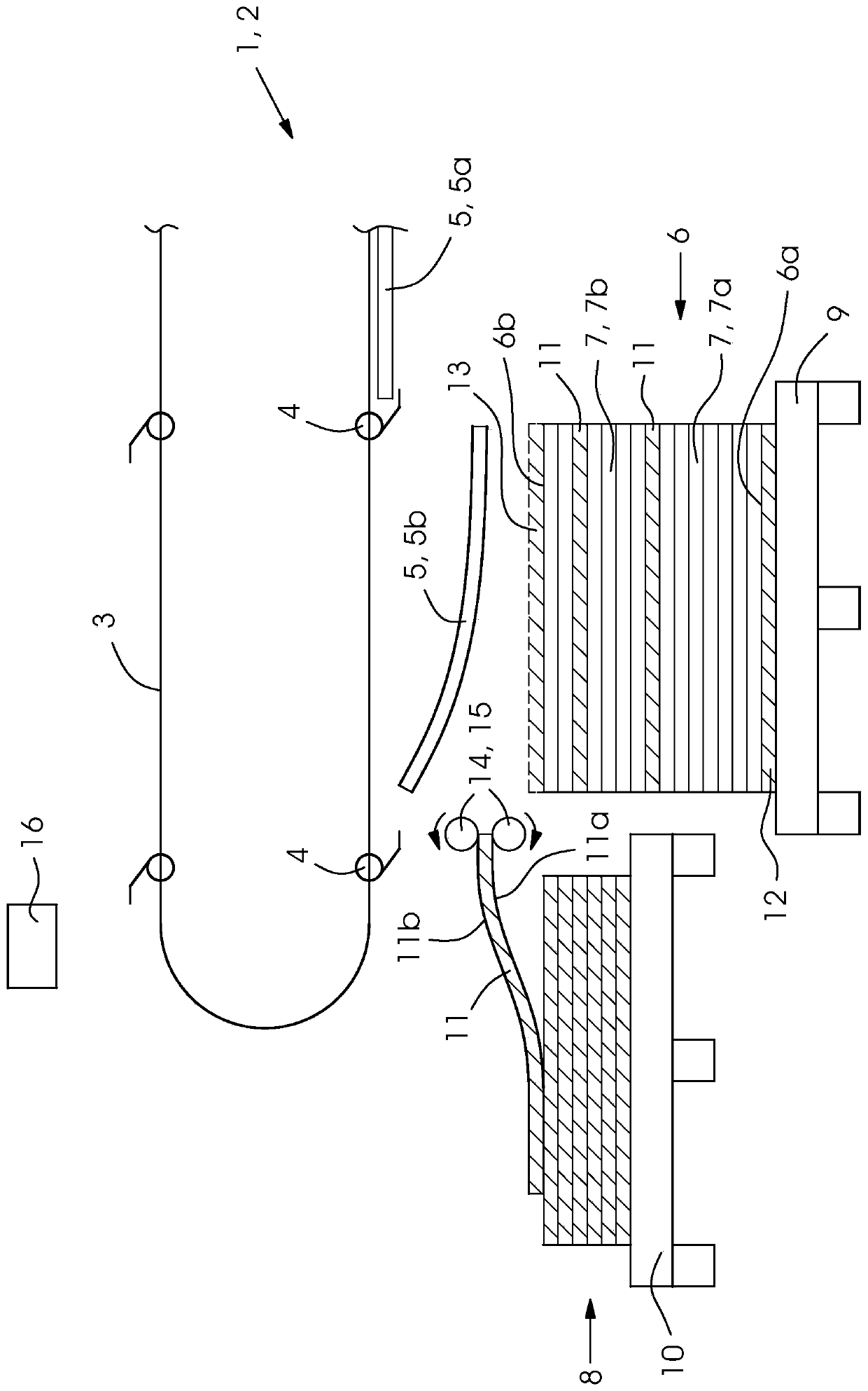

[0037] figure 1A printing press 1 is shown, such as an ink printing press or an offset printing press. The printing press 1 comprises a stacker 2 comprising a chain conveyor 3 with grippers 4 for printed sheets 5 . The reference numeral 5 a designates a conveyed sheet (in gripper lock), and the reference numeral 5 b designates a dropped sheet deposited on the sheet stack 6 (sheet in flight phase). The sheet stack 6 has a bottom side 6 a and a top side 6 b. The sheet stack 6 rests on a stack support 9 and is preferably height-adjustable. In the vicinity of the stack carrier 9 there is an auxiliary stack carrier 10 on which the auxiliary stack 8 formed from the intermediate layer 11 is arranged. The auxiliary stacking bracket 10 is also preferably height adjustable.

[0038] According to the method according to the invention, an intermediate layer 11 (at least one, preferably a plurality of intermediate layers) is introduced into the sheet stack 6 . In this way, a section 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com