Magnetic alignment device and magnetic printing equipment

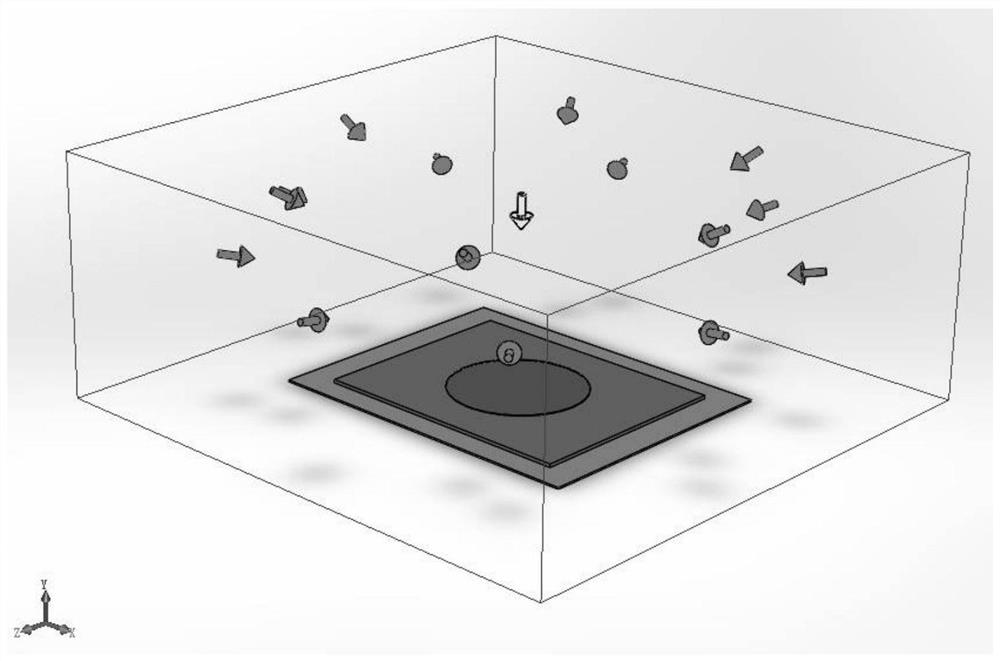

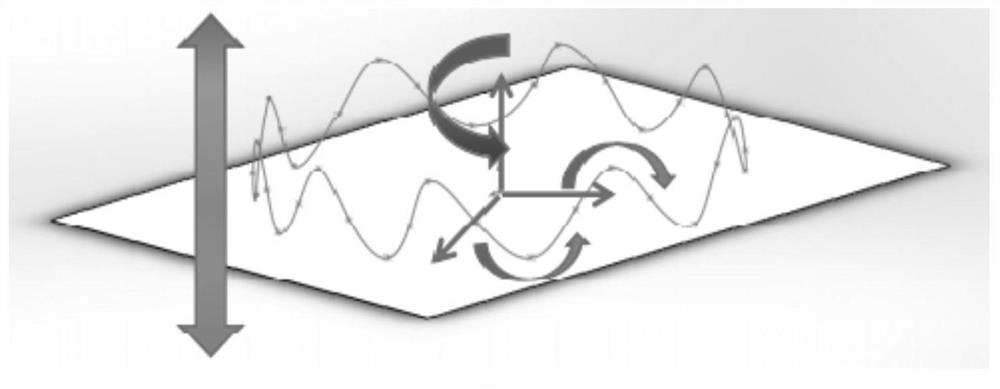

A magnetic printing and magnetic orientation technology, applied in the field of magnetic orientation, can solve the problems of monotonous effect, unsatisfactory, complex structure, etc., and achieve the effect of changing the orientation effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

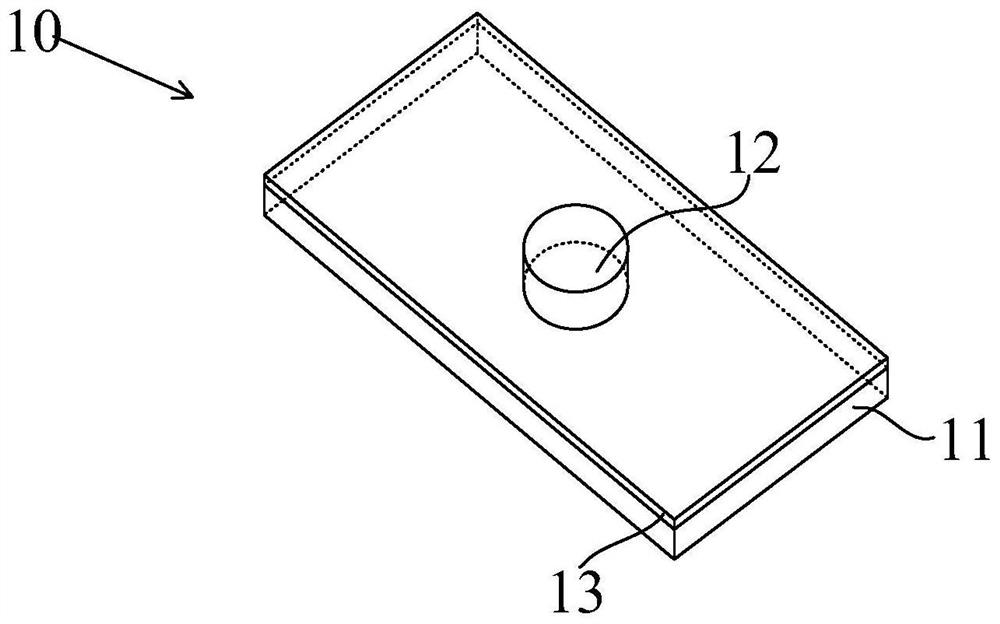

Embodiment 1

[0052] Such as image 3 and Figure 4 As shown, the main surface of the first magnet 11 is arranged in a quadrangular shape. The first magnet 11 is a plate-like structure with a length of 50mm×width of 25×height. The second magnet 12 is a cylinder with a radius of 4 mm×a height of 4 mm. The demagnetizing body 13 is a cuboid with a length of 50 mm×a width of 25×a height of 2. The orthographic projection of the second magnet 12 on the plane where the demagnetizing body 13 is located overlaps with the orthographic projection of the geometric center of the main surface of the first magnet 11 on the plane where the demagnetizing body 13 is located. refer to Figure 5 , Figure 5 yes image 3 The magnetization pattern (a) of the magnetic orientation device 10 shown and image 3 The comparison schematic diagram of the fixed magnetization pattern (b) after the demagnetization body 13 is removed in the magnetic orientation device 10 shown. From Figure 5 It can be seen that th...

Embodiment 2

[0054] Such as Figure 6 and Figure 7 As shown, the main surface of the first magnet 11 is arranged in a triangular shape. The first magnet is a plate-shaped structure with a side length of 38 mm×a thickness of 2 mm. The second magnet 12 is arranged in a cylindrical shape. The orthographic projection of the second magnet 12 on the plane where the demagnetization body 13 is located overlaps with the orthographic projection of the geometric center of the main surface of the first magnet 11 on the plane where the demagnetization body 13 is located. The demagnetizing bodies 13 are arranged in a triangular shape. The demagnetizing body 13 is a plate-shaped structure with a side length of 38mm×0.7mm. A piece of demagnetizing body 13 is arranged between the first magnet 11 and the second magnet 12 . refer to Figure 8 , Figure 8 yes Figure 6 The magnetization pattern (c) of the magnetic orientation device 10 shown and Figure 6 The comparison schematic diagram of the fixe...

Embodiment 3

[0056] Such as Figure 9 and Figure 10 As shown, the main surface of the first magnet 11 is arranged in a triangular shape. The first magnet is a plate-shaped structure with a side length of 38 mm×a thickness of 2 mm. The second magnet 12 is arranged in a cylindrical shape. The orthographic projection of the second magnet 12 on the plane where the demagnetization body 13 is located overlaps with the orthographic projection of the geometric center of the main surface of the first magnet 11 on the plane where the demagnetization body 13 is located. The demagnetizing bodies 13 are arranged in a triangular shape. The demagnetizing body 13 is a plate-shaped structure with a side length of 38mm×0.7mm. Two demagnetizing bodies 13 are arranged between the first magnet 11 and the second magnet 12 . refer to Figure 11 , Figure 11 are magnetic or magnetizable pigment flakes in Figure 9 A schematic diagram of the fixed magnetism effect after magnetic orientation is performed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com