Gas transmission system and gas transmission method

A technology of gas transmission and gas, which is applied in gas/liquid distribution and storage, pipeline system, container filling method, etc., and can solve problems such as the limitation of supply gas usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, features and advantages of the present invention more comprehensible, several preferred embodiments are specifically cited below, together with the accompanying drawings, which are described in detail as follows.

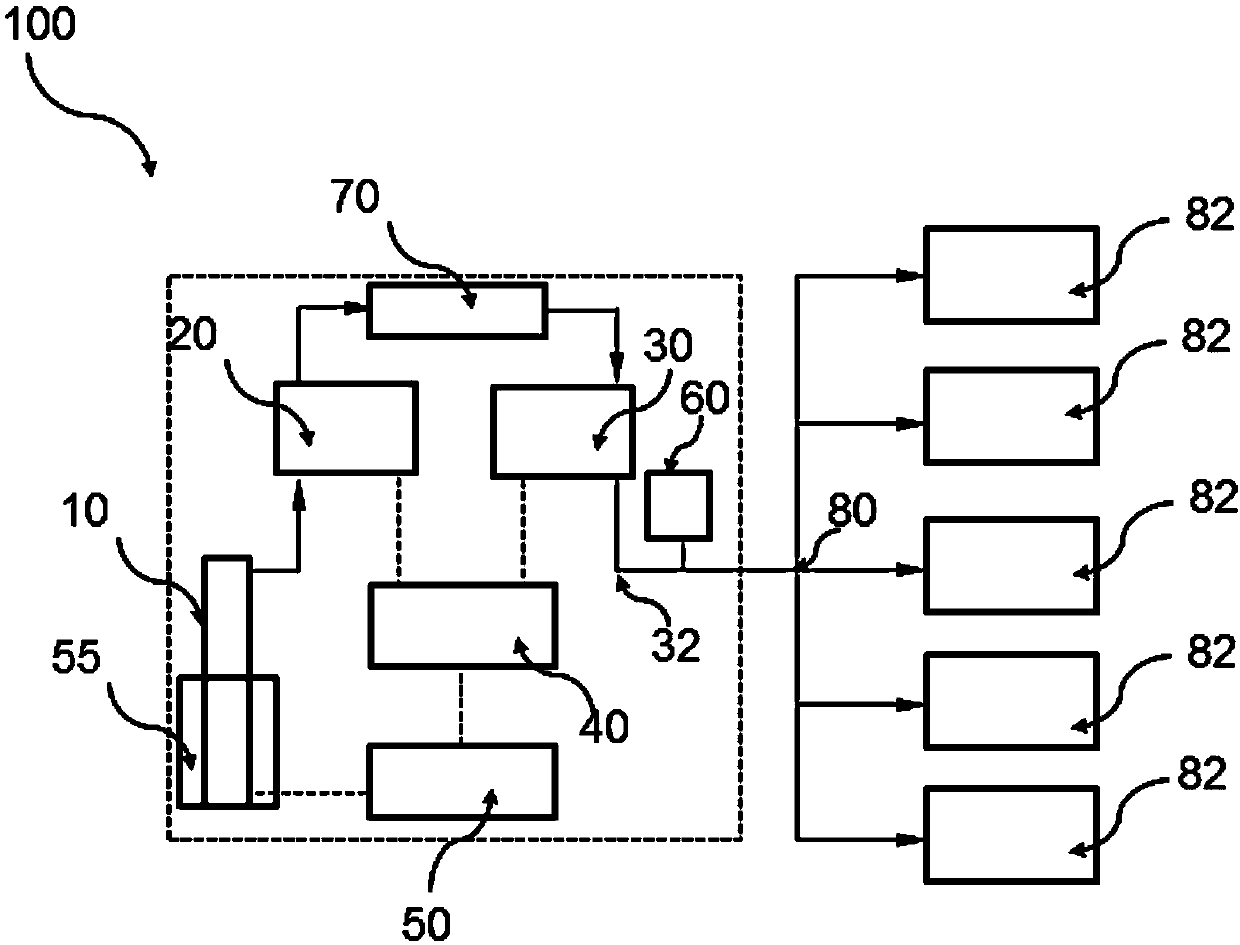

[0038] figure 1 A schematic representation of an implementation of a gas delivery system according to the invention is shown. The gas transmission system 100 mainly includes: a gas cylinder 10 ; an electronic mass flow controller 20 ; an electronic mass flow meter 30 and a controller 40 .

[0039] The electronic mass flow controller 20 is connected to the gas cylinder 10 and is used to control a gas output in the gas cylinder 10 . The gas cylinder 10 contains a liquid precursor or a gas precursor. In one embodiment, the gas cylinder 10 contains low-volatility vapor pressure process gas, such as SiH2Cl2, WF6, HF, Cl2, Si2H6, and the like. A typical mass flow controller 20 is controlled by a valve (valve), which can be manually ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap