An automatic spraying robot

An automatic spraying and robotic technology, which is applied in the directions of manipulators, spraying devices, manufacturing tools, etc., can solve the problems of difficulty in ensuring spraying quality, low degree of automation, and difficulty in controlling spray heads, and achieves consistent, guaranteed spraying quality, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

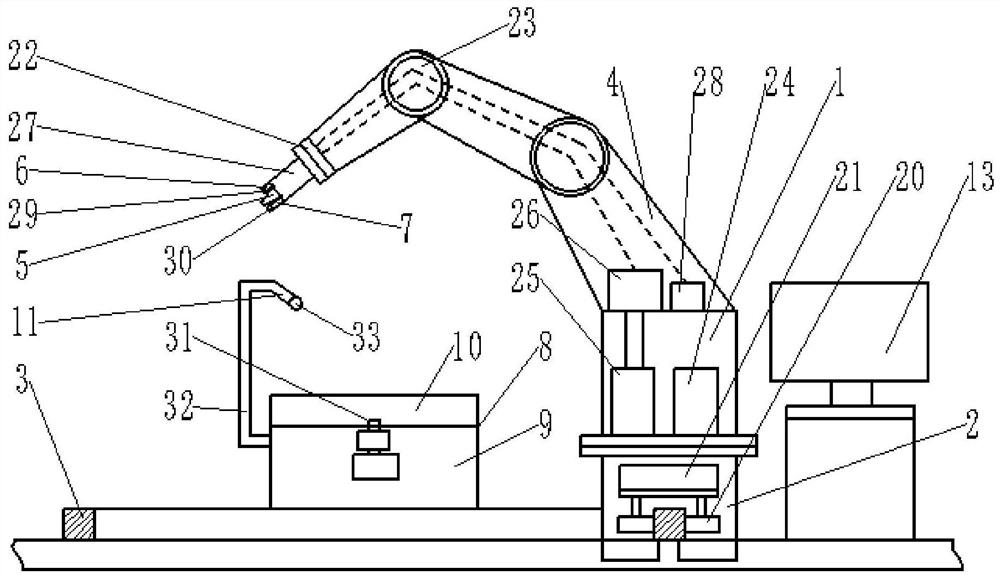

[0047] Such as Figure 1 to Figure 3 As shown, the invention provides an automatic spraying robot, comprising:

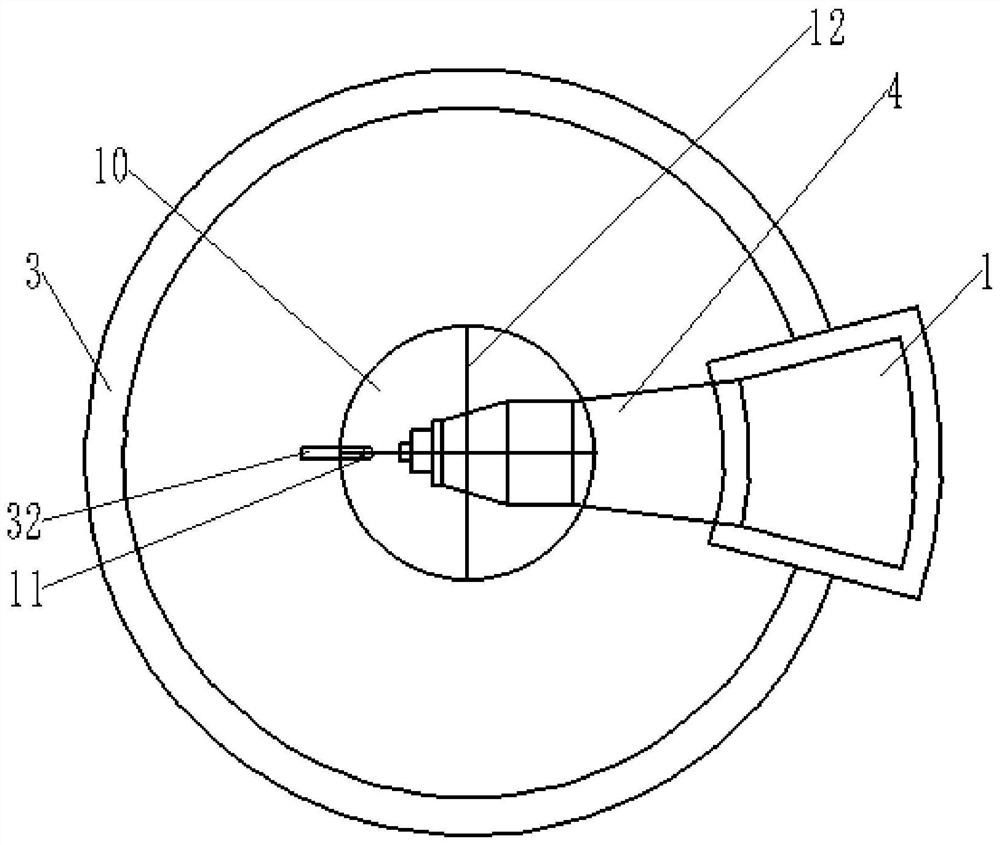

[0048] Spraying device 1, the lower end of the spraying device 1 is provided with a sliding base 2, the lower end of the sliding base 2 is slidably connected with an annular track 3, the upper end of the sliding base 2 is provided with a spraying arm 4, and the front end of the spraying arm 4 is provided with a spray head 5. A first image acquisition component 6 and a distance measuring component 7 are arranged on one side of the spray head 5;

[0049] Placement platform 8 is arranged in the center of circular track 3, and the lower end of said placement platform 8 is provided with a placement frame 9, and above the placement frame 9, a turntable 10 is arranged, and a second image acquisition assembly 11 is arranged above one side of said turntable 10, The upper surface of the turntable 10 is provided with a coordinate scale 12;

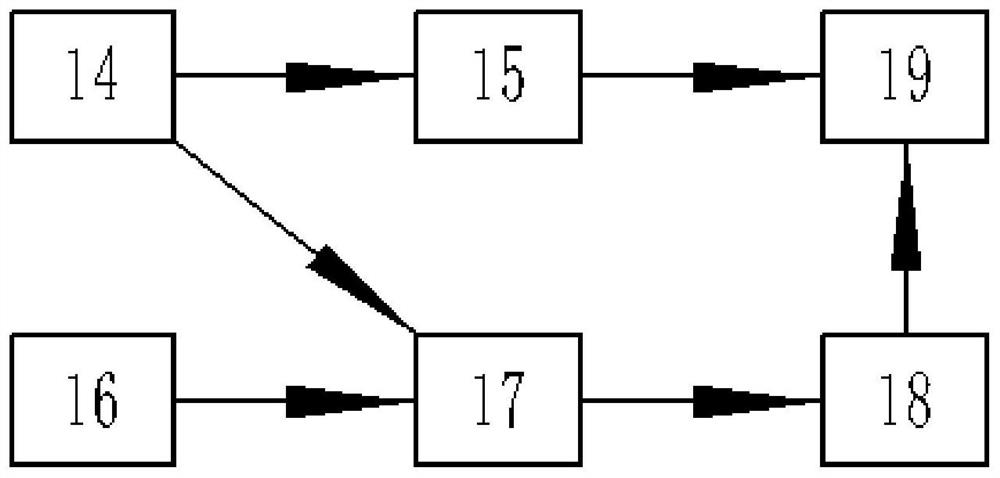

[0050] The control device 13 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com