Locking clamp and collimation inspection device

A technology of locking clips and locking segments, which is applied to aiming devices, workpiece clamping devices, manufacturing tools, etc., can solve the problems of complexity, unfavorable production efficiency, and long time-consuming scopes, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

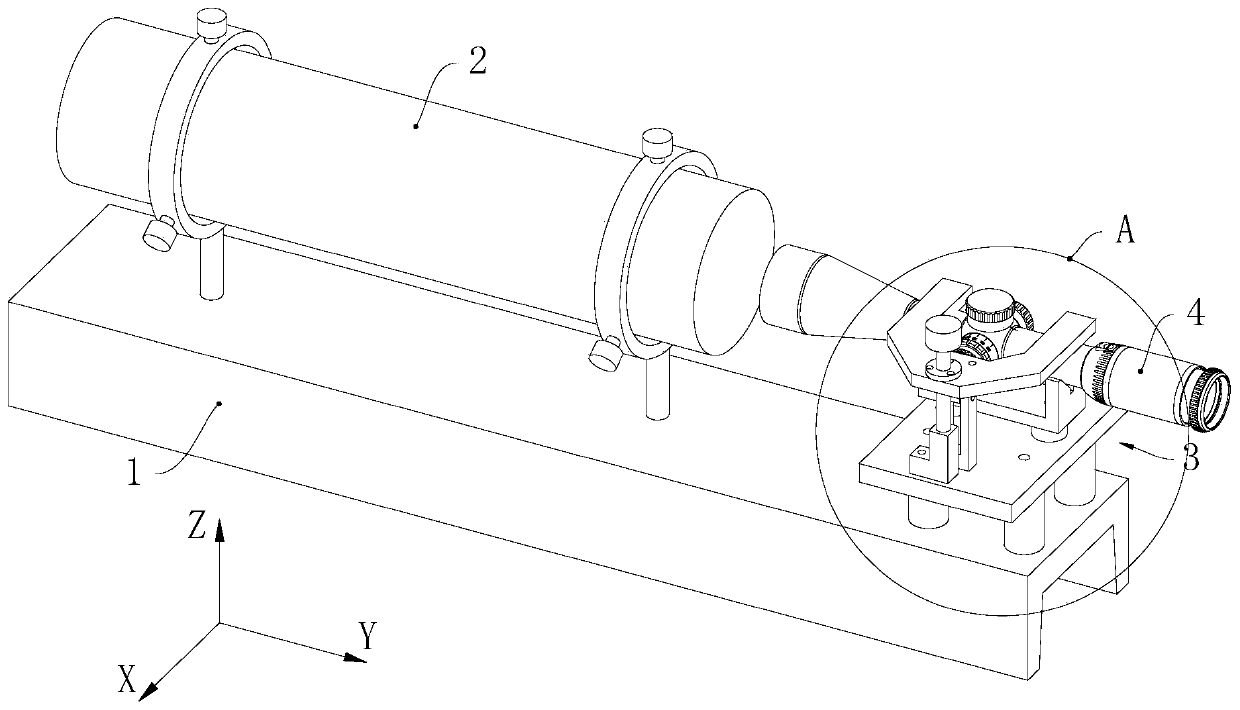

[0026] This example refers to figure 1 The spatial Cartesian coordinate system shown is described.

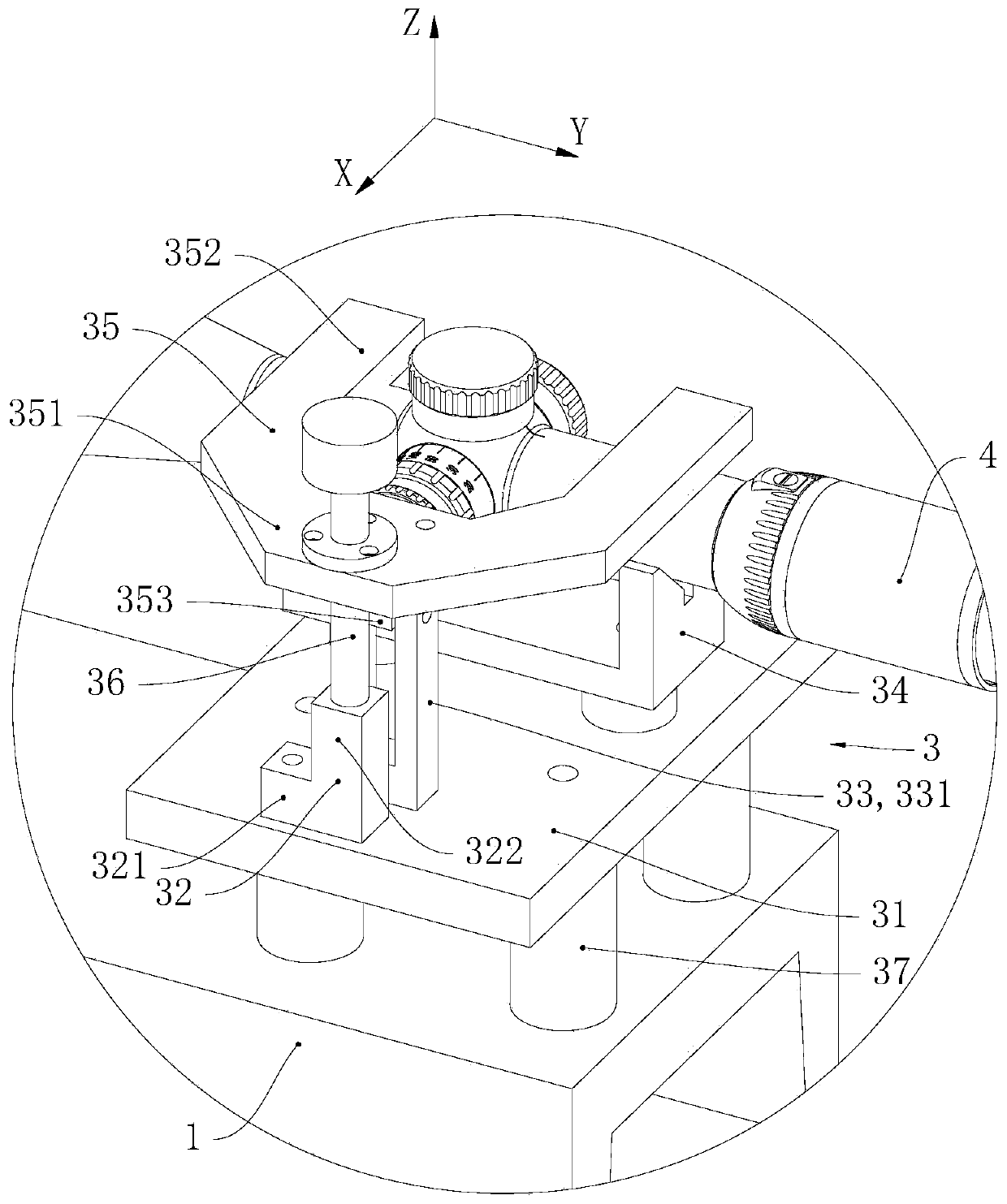

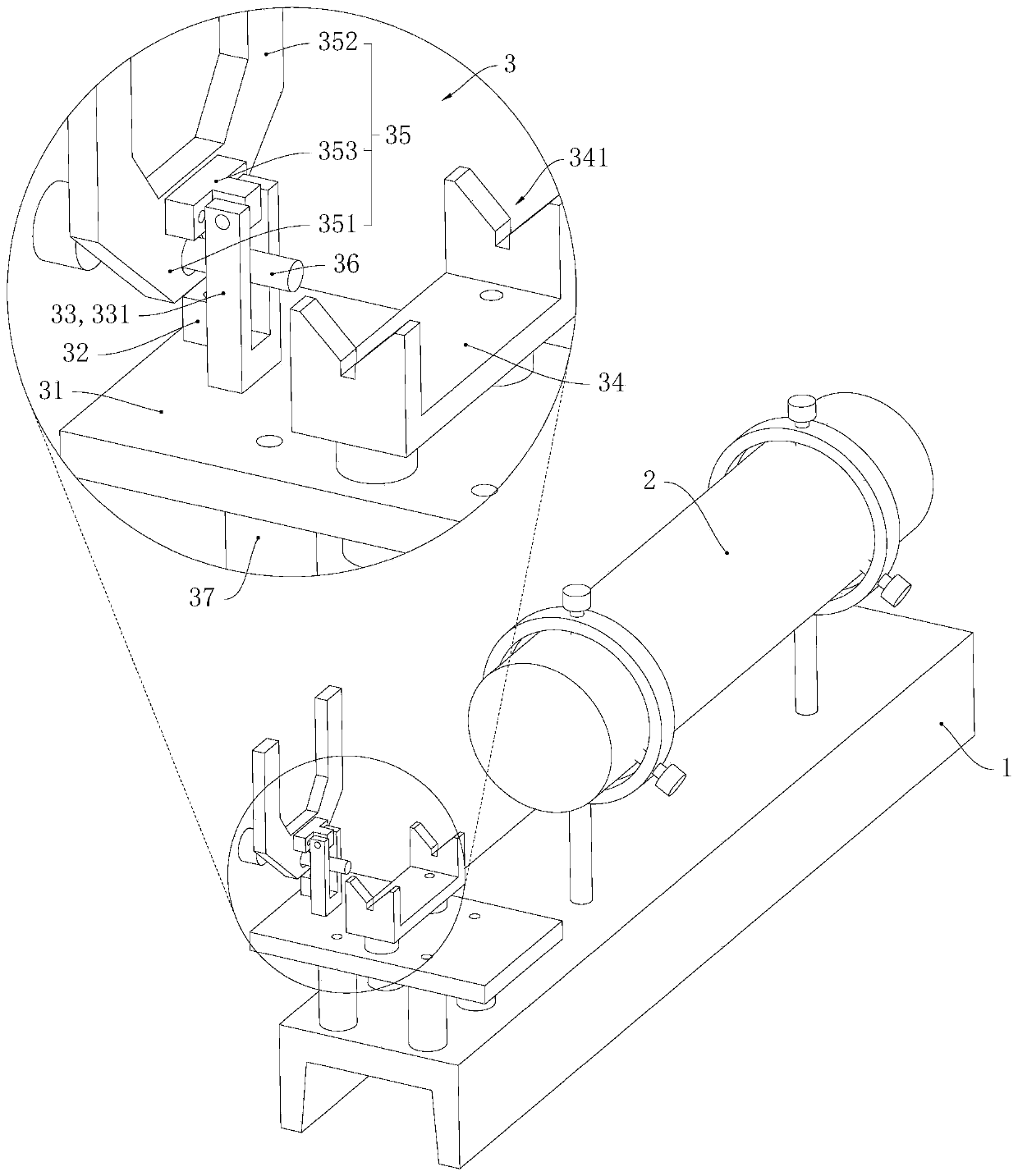

[0027] Please refer to Figure 1 to Figure 2 , the aiming inspection device of this embodiment includes a detection table 1, a collimator 2 and a locking fixture 3 of this embodiment, the collimator 2 and the locking fixture 3 are all installed on the detection table 1, and the axis of the collimator 2 The direction is along the Y-axis direction, the collimator 2 and the locking fixture 3 are distributed along the Y-axis direction, and the locking fixture 3 clamps the locking scope 4 .

[0028] Please refer to Figure 1 to Figure 2 , the locking fixture 3 includes an installation base 31, a hinged frame 33, a positioning tooth clamp 34, a clamp arm 35 and an adjustment assembly, the adjustment assembly includes a support block 32 and an adjustment bolt 36, the installation base 31 is fixed on the detection table 1, and the positioning teeth clamp 34 and the hinged frame 33 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com