Special tool for clamping PVC (polyvinyl chloride) pipe

A PVC pipe and clamping technology, which is applied in metal processing and other directions, can solve the problems of prolonging the production process and consuming a lot of time, and achieve the effects of improving production efficiency, reducing time and cost, and reducing the time for clamping and unclamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

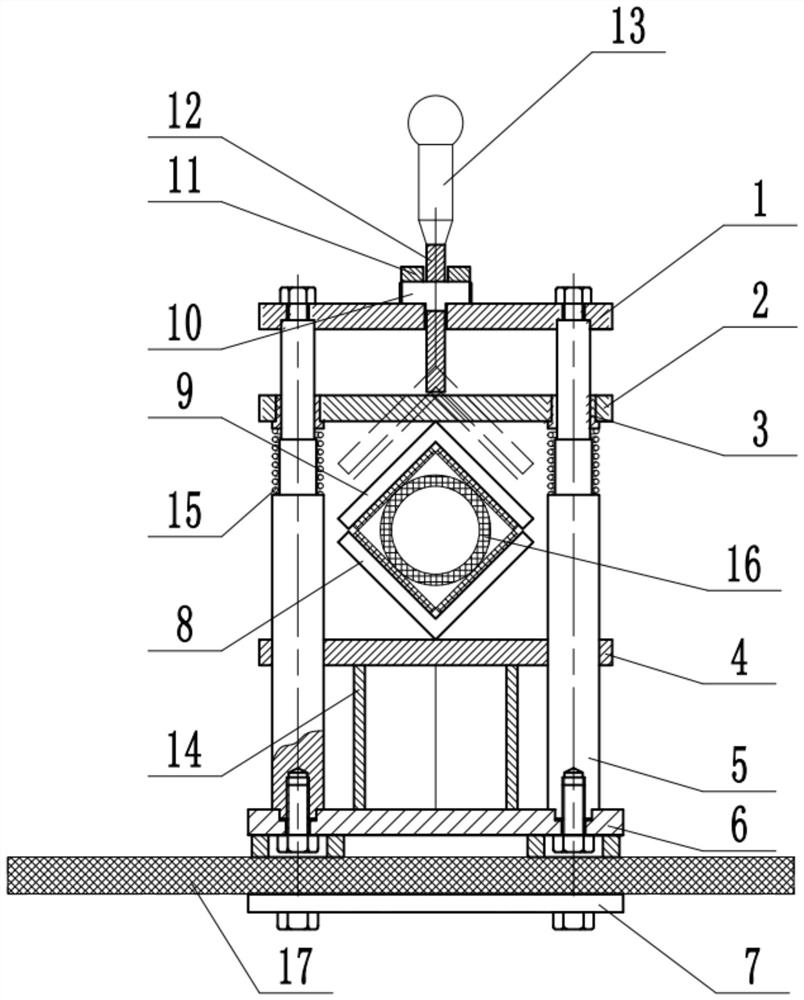

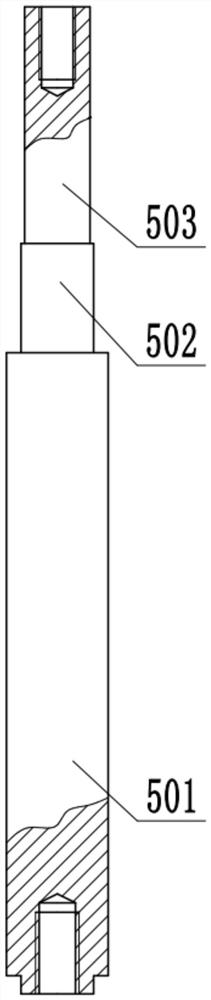

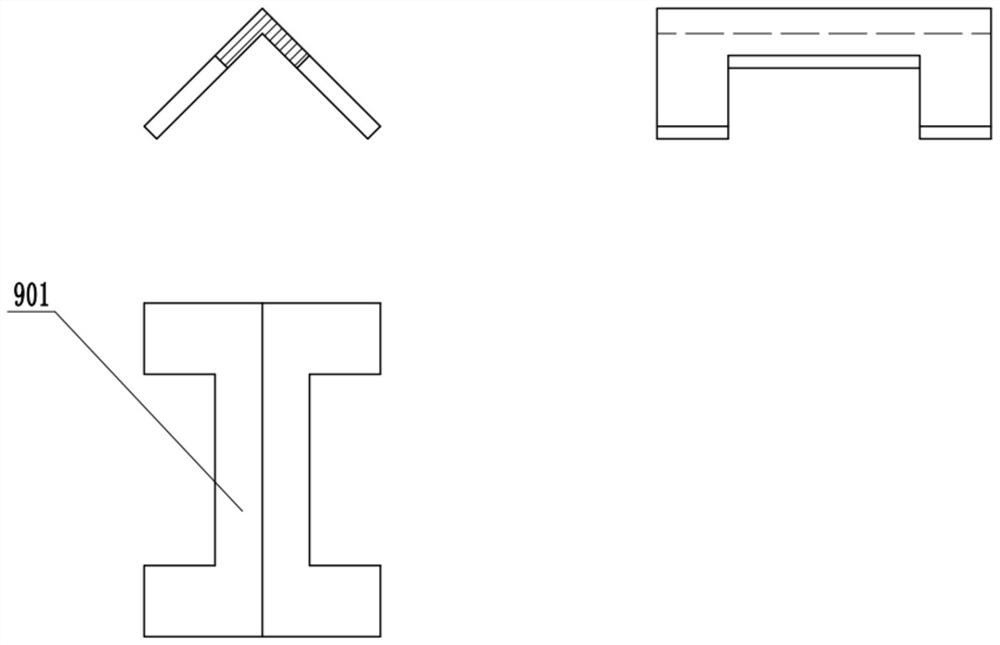

[0022] The reference signs in the drawings of the description include: top plate 1, upper platen 2, guide sleeve 3, lower platen 4, guide post 5, first column section 501, transition column section 502, second column section 503, bottom plate 6, pad Plate 7, lower pressing block 8, upper pressing block 9, clip block 901, axle pin 10, axle pressing block 11, cam 12, handle 13, telescopic rod 14, compression spring 15, PVC pipe 16, workbench 17.

[0023] A kind of special tooling for PVC pipe clamping, for example figure 1 As shown: it includes a workbench 17 and four guide columns 5 symmetrically arranged on the upper surface of the workbench 17. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com