Cloth cutting device for textile production

A cutting device and fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of low cutting efficiency, low cutting precision, and deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

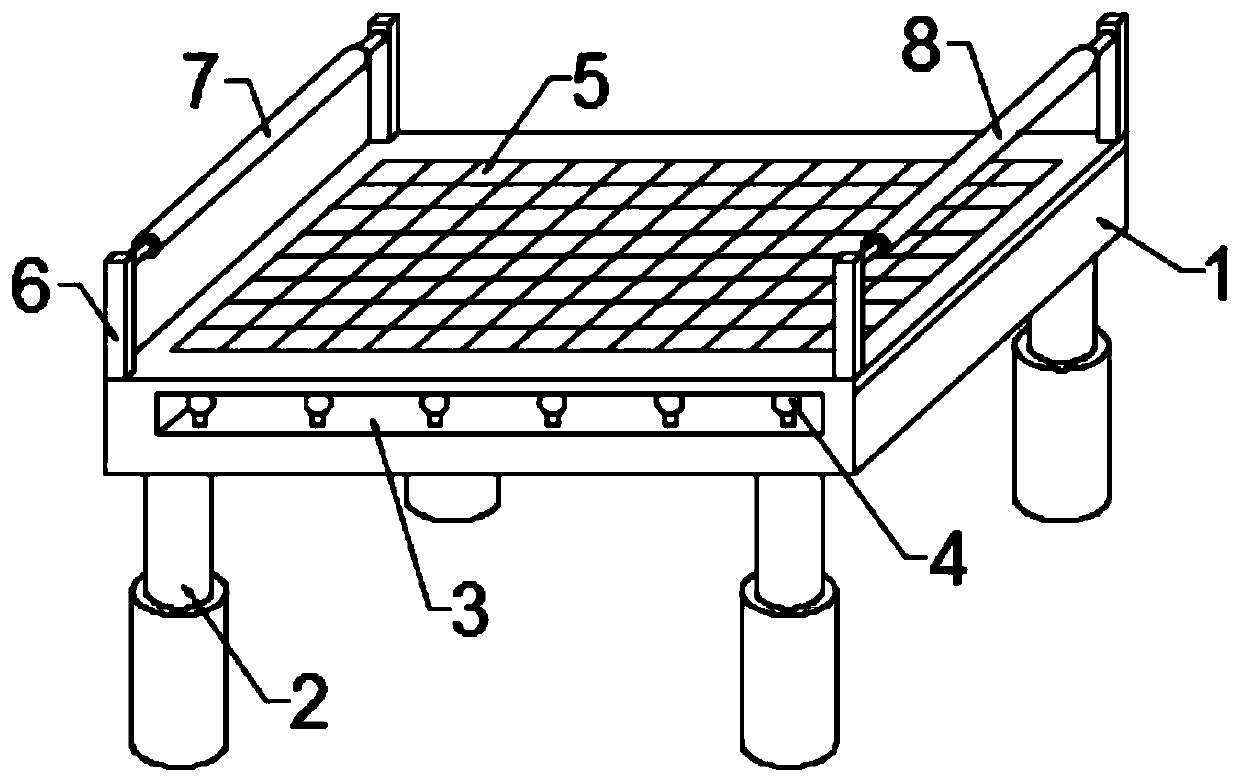

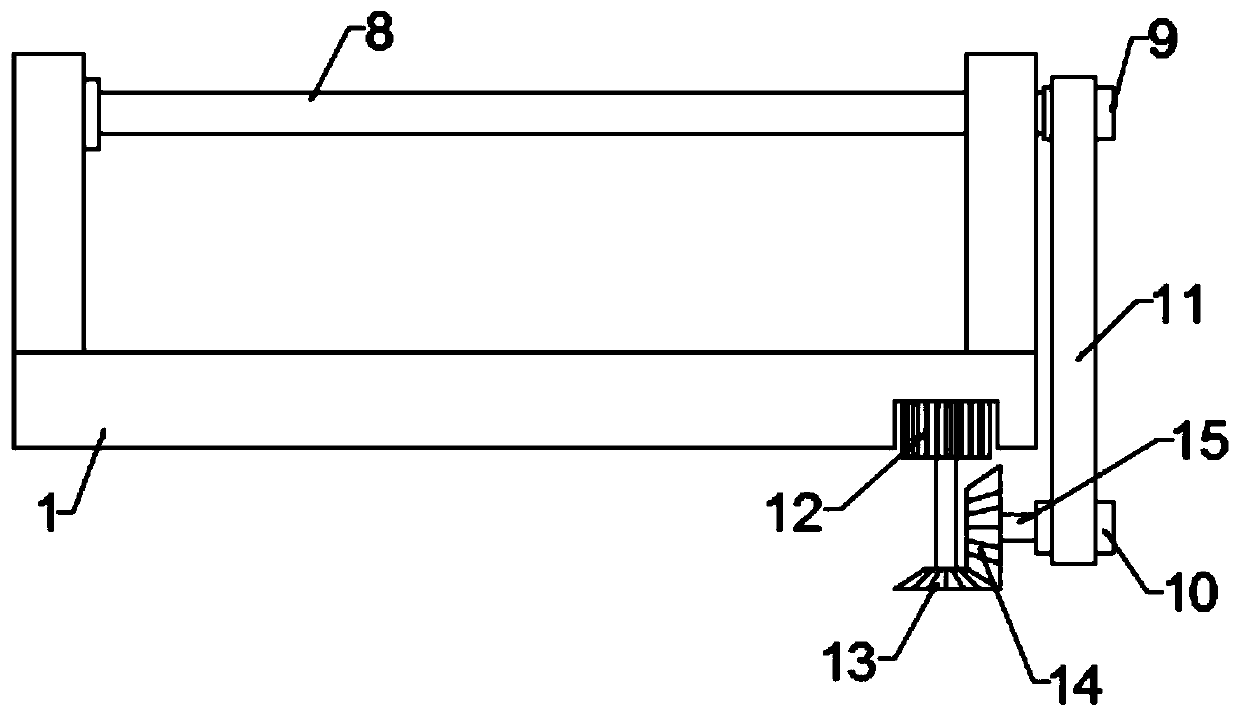

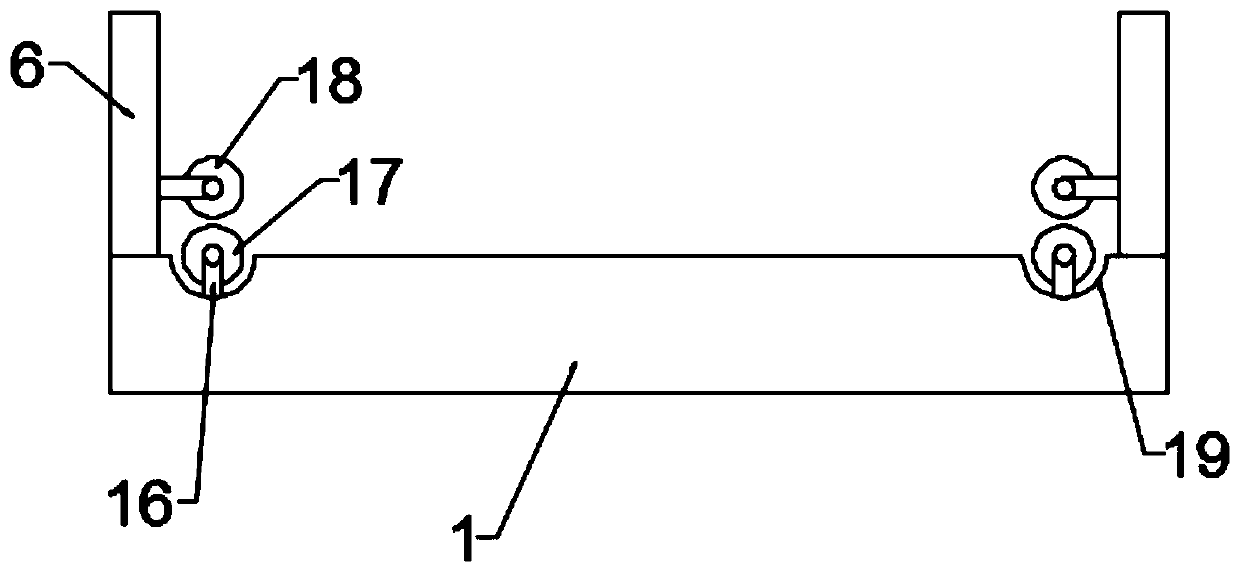

[0041] see Figure 1~5 In one embodiment provided by the present invention, a cloth cutting device for textile production includes a cutting platform 1, the bottom end of the cutting platform 1 is fixed with an automatic telescopic column 2, and the top of the cutting platform 1 is a table top 5, The two ends of the upper surface of the table top 5 are provided with a cloth pressing mechanism; the top of the table top 5 is provided with a winding roller 7 and a traction roller 8; the upper surface of the table top 5 is provided with a vertical cutting mechanism and a horizontal cutting mechanism, The vertical cutting mechanism includes a horizontal guide rail 20 and a lateral movement bar 22 installed on the horizontal guide rail 20, and the horizontal cutting mechanism includes a vertical guide rail 21 and a vertical movement bar installed on the vertical guide rail 21 23. The cutting assembly is slidably installed on the lateral movement bar 22 and the vertical movement bar ...

Embodiment 2

[0053] see Figure 6 and Figure 8 , In yet another embodiment provided by the present invention, the cutting assembly includes a cutting block 30, and a slider 31 is fixed on the inner side of the cutting block 30; A chute 29 is provided; the cutting block 30 is slidably installed on the lateral movement bar 22 and the vertical movement bar 23 through the sliding block 31 and the chute 29 .

[0054] Further, the cutting assembly includes a cutting knife 33, and the cutting knife 33 is slidably installed in the knife groove 32 provided outside the slider 31, and the inner wall of the knife groove 32 is provided with a spring buckle 36, and the cutting knife 33 is provided with an adjustment hole 35 matched with the spring buckle 36 , and a pressing plate 34 is fixed on the top of the scissors 33 .

[0055] Before cutting, the cutting knife 33 cooperates with the adjustment hole 35 at the lower part through the spring buckle 36, and the blade of the cutting knife 33 is hidden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com