Well washing valve capable of achieving forward and reverse circulating well washing

A technology for reverse circulation well flushing and well flushing valve, which is applied in the direction of flushing wellbore, wellbore/well components, earth-moving drilling, etc., can solve the problem of difficult to meet the needs of downhole tubing cleaning, and achieves simple structure, simple operation and convenience. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments. It should be noted that, on the premise of not conflicting, the various embodiments or technical features described below can be combined arbitrarily to form new implementations. example. Unless otherwise specified, the materials and equipment used in this embodiment can be purchased from the market.

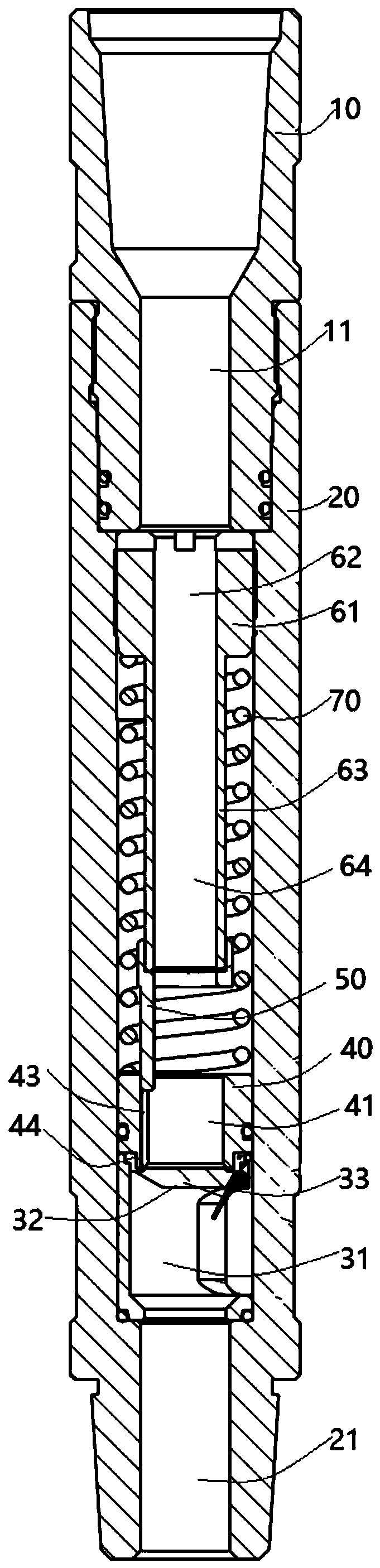

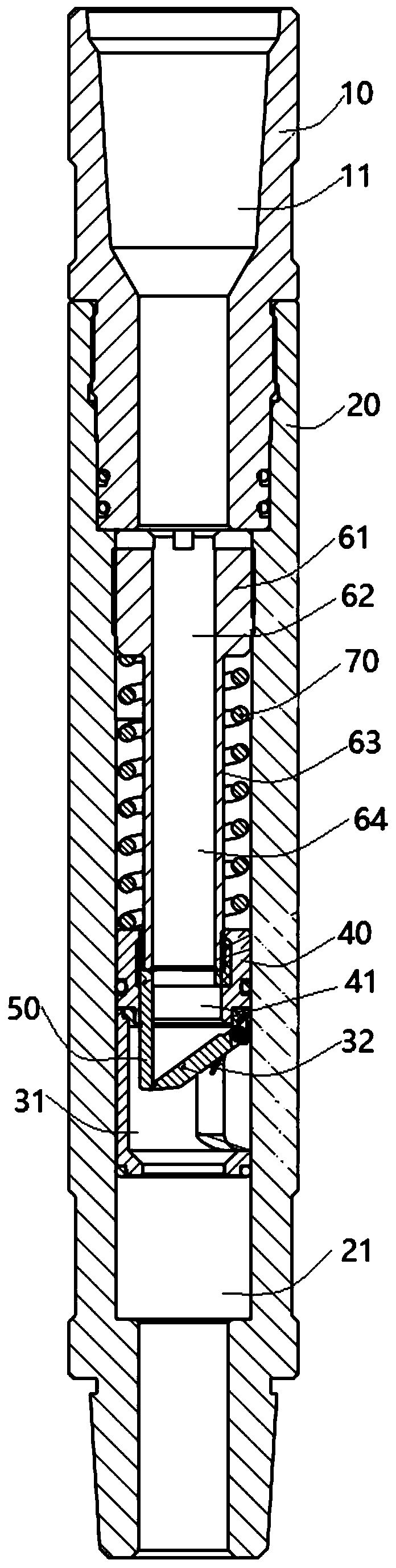

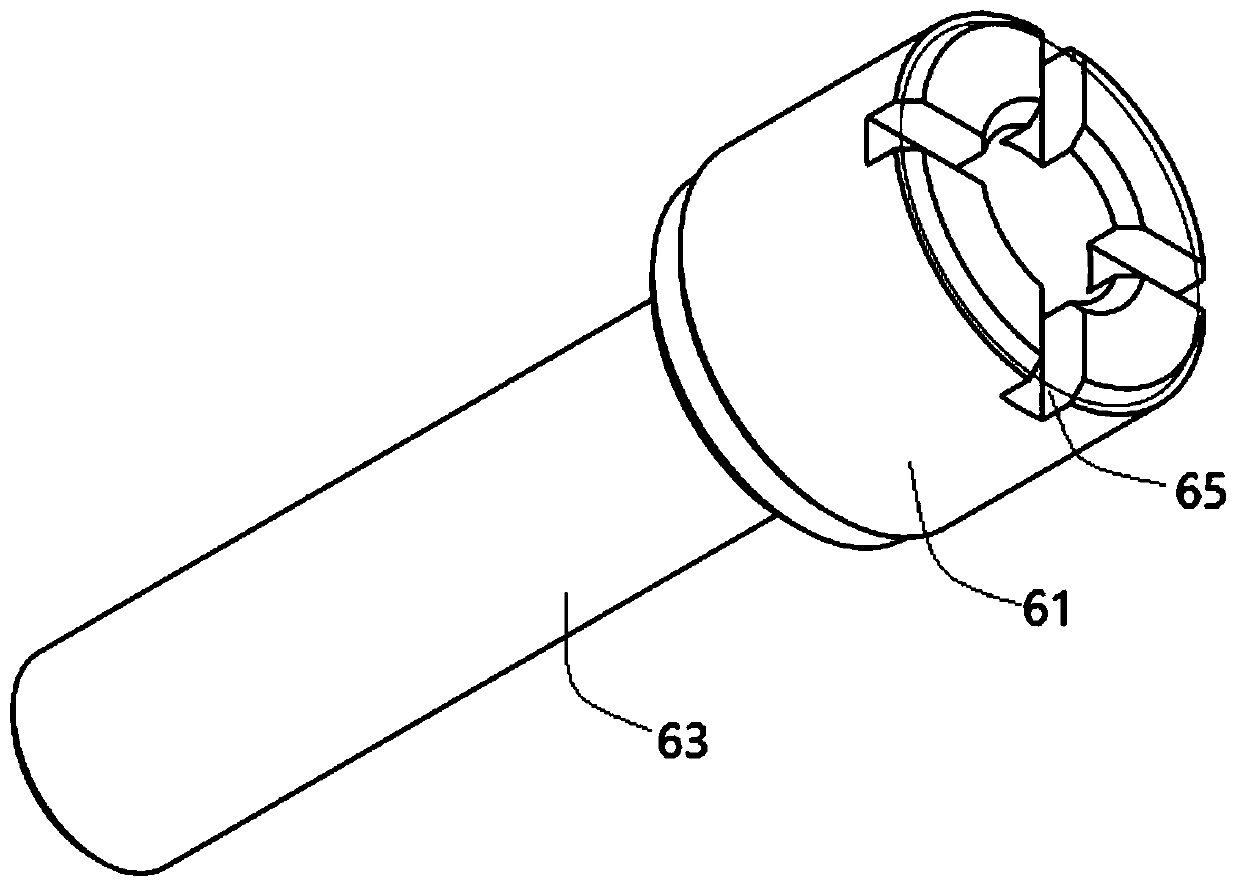

[0033] see Figure 1-4 , a well flushing valve capable of realizing positive and negative circulation flushing, comprising an upper joint part 10 and a lower joint part 20 sleeved on the lower part of the upper joint part 10;

[0034] The upper joint part 10 is provided with a hollow cavity 11 axially penetrating its top and bottom, and the lower joint part 20 is provided with an installation cavity 21 axially penetrating its top and bottom, and the installation cavity 21 communicates with the hollow cavity 11; the upper joint part 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com