Low-power-consumption and high-precision hot fluid metering method

A measurement method and high-precision technology, applied to the volume/mass flow generated by electromagnetic effects, and the application of electromagnetic flowmeters to detect fluid flow, etc., can solve the problems of inaccurate flow measurement, difficult application, unstable water flow, etc., and improve accuracy degree, improve measurement accuracy and stability, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

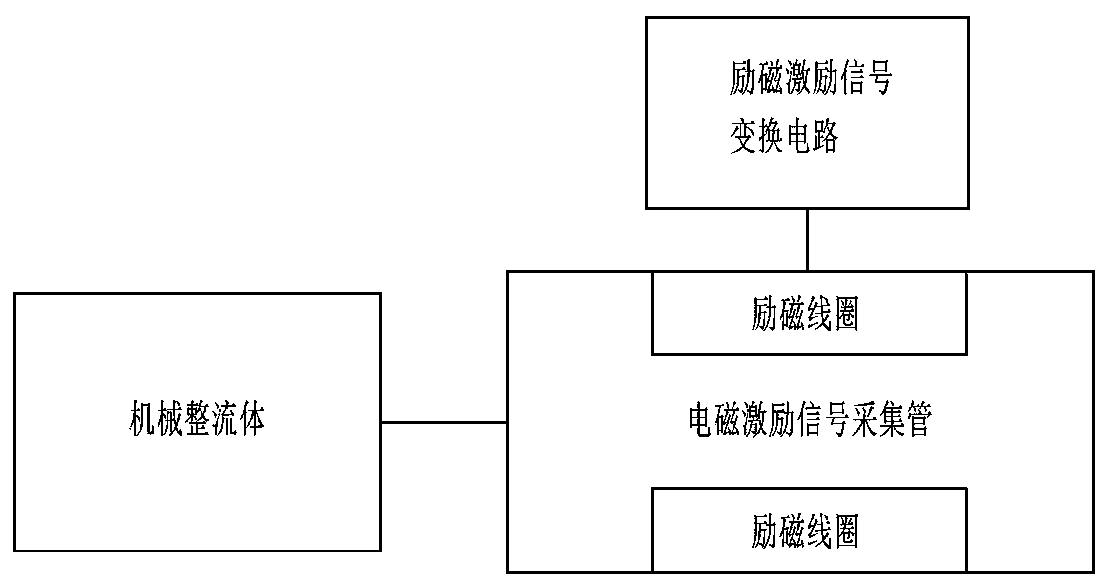

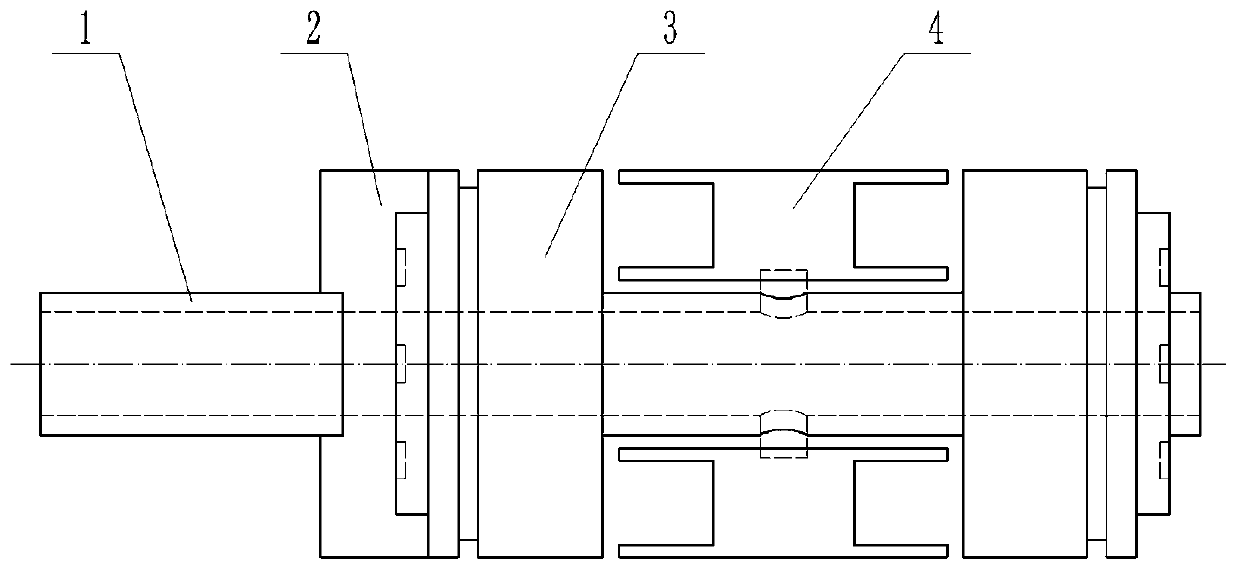

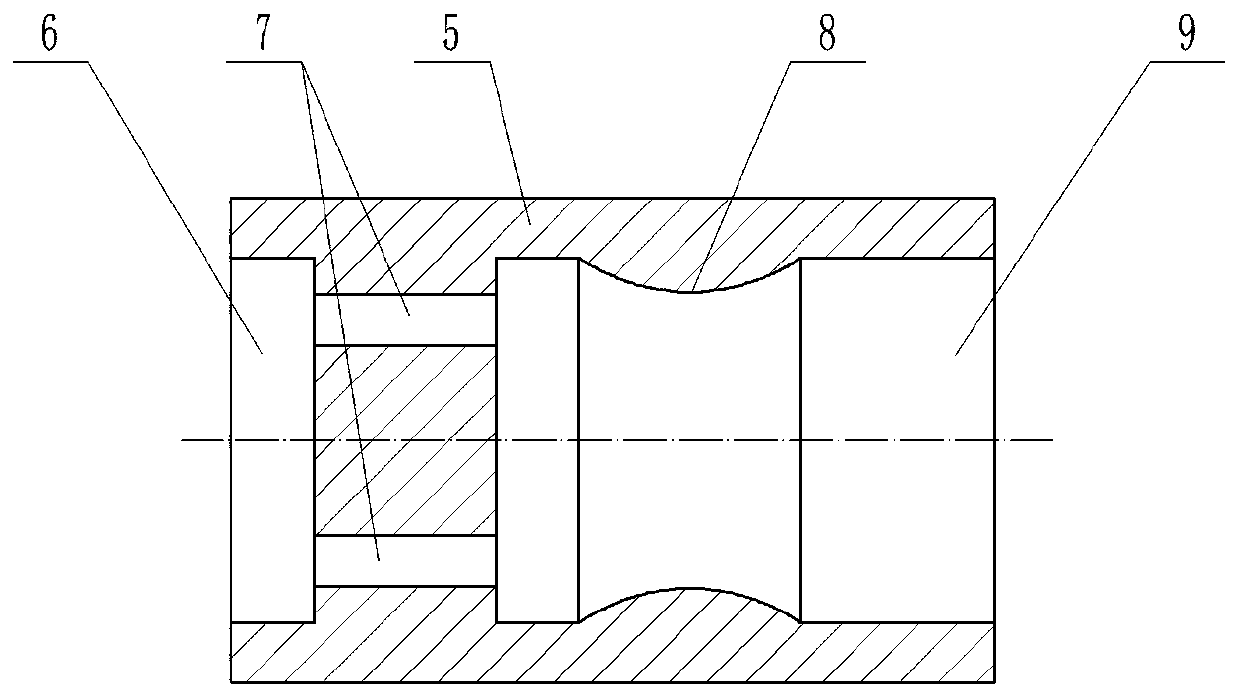

[0024] according to Figure 1~6 The specific steps of the present invention are described in detail. The low-power-consumption and high-precision thermal fluid metering method includes the following steps: step 1, the fluid in the pipeline enters the rectification holes 7 through the rectification inlet 6 of the mechanical rectifier body 1, and then the rectification holes 7 divide the pipeline The turbulent flow and turbulent flow in the flow are rectified and adjusted to make it a straight flow, so as to improve the measurement accuracy and stability of the electromagnetic flowmeter. The mechanical rectifier body 1 is composed of a rectifier body body 5 , the front end of the rectifier body body 5 is provided with a rectification inlet 6 , and the rectification inlet port 6 is connected to several rectification holes 7 arranged on the front side of the rectifier body body 5 . Several rectification holes 7 arranged inside the rectifier main body 5 of the mechanical rectifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com