A planarization treatment method for ultra-thick film

A processing method and flattening technology, applied in the field of flattening processing of ultra-thick adhesive films, can solve the problems of reduced product reliability, large thickness of metal lines, and high process difficulty, and achieves the goal of reducing the number of times and increasing the uniformity of coverage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as Figure 1 to Figure 11 Shown, a kind of planarization treatment method of super thick adhesive film specifically comprises the following steps:

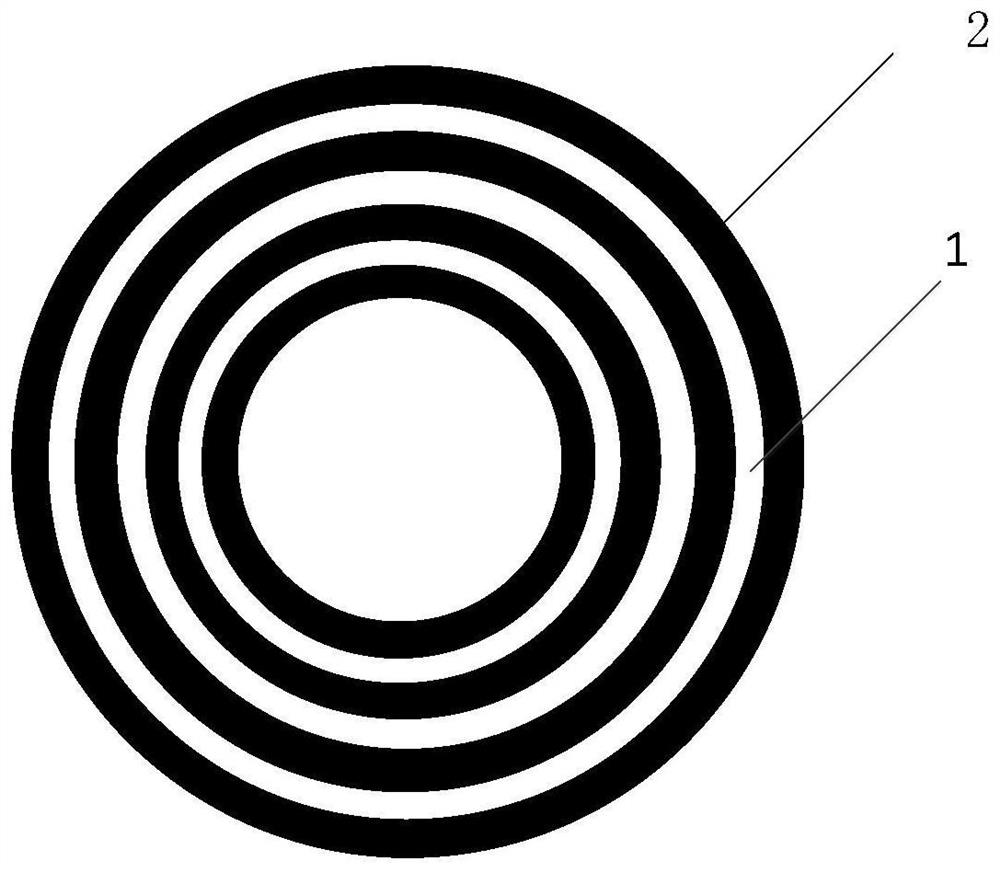

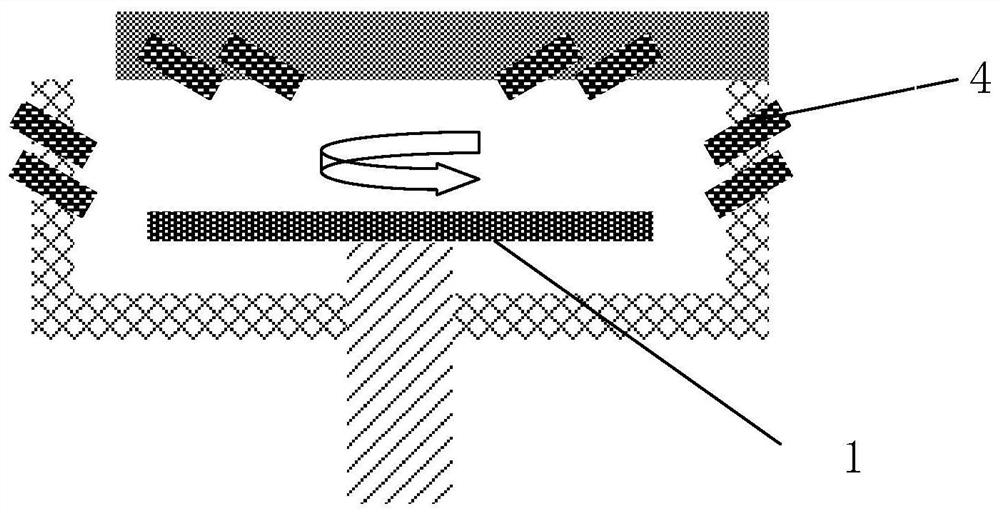

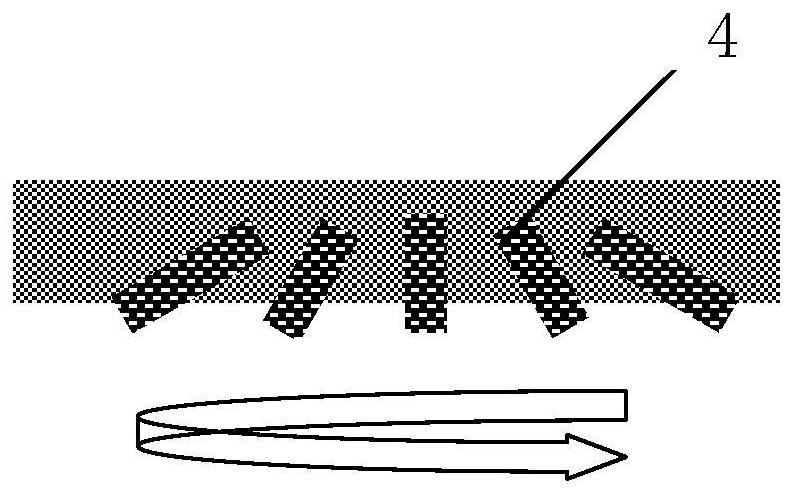

[0034] 101) Preliminary spraying step: heating the bottom of the circuit carrier 1 with the circuit metal wire 2 at 50 to 150 degrees; the height of the circuit metal wire 2 is between 10um and 200um, and the width is between 1um and 1000um. The circuit metal wire 2 itself has a one-layer or multi-layer structure, and its material is a mixture of one or more of titanium, copper, aluminum, silver, palladium, gold, thallium, tin, and nickel. Apply the photoresist 3 on the upper surface of the circuit carrier 1 by direct pasting process, and let it stand for a period of time, the rest time is between 10 seconds and 100 seconds; then rotate the coated photoresist 3, and the speed is controlled at 100 revolutions to 10,000 revolutions per second; wherein, the heating method includes infrared heating to directly heat the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com