Salt dissolving tank liquid level optimization and control method

A technology of optimized control and liquid level controller, which is applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., and can solve problems such as too large fluctuations in liquid level measurement values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

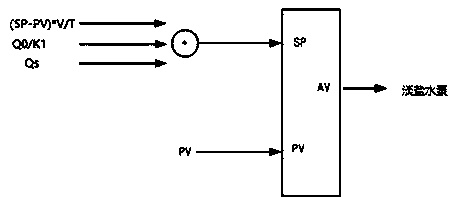

[0011] The technical solution includes the following aspects: (1) establishment of the vertex curve; (2) calculation of water inflow; (3) optimization control; (4) liquid level controller.

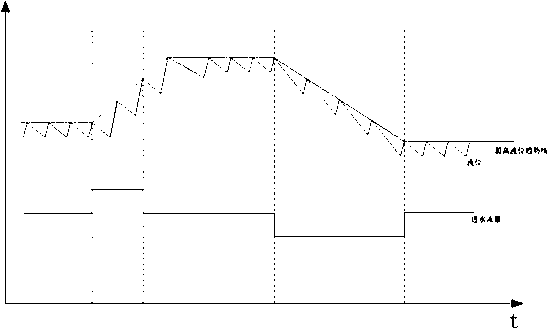

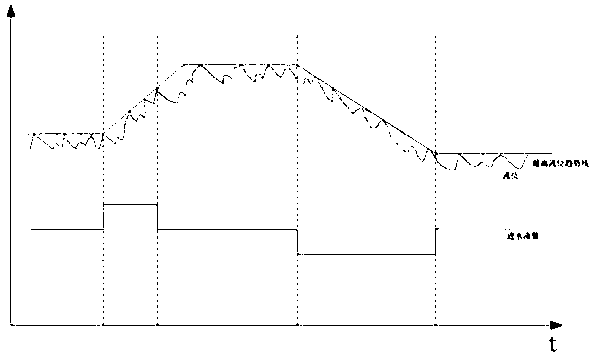

[0012] The establishment of the above (1) vertex curve: For the variable of liquid level, each scan cycle of the system is compared with the value of the previous cycle. If the value of the current cycle is greater than the value of the previous cycle, the value of this cycle is Record it and compare it with the next cycle. If the current cycle is smaller than the previous cycle, record the previous cycle, and then compare it with the value of the next cycle. Finally, the highest output value will always be maintained. If the highest value remains unchanged for several cycles, the highest value of the current salting cycle is considered to be the current value. When the next salting cycle starts, the highest value of the previous cycle will be delayed by the corresponding salting cycle unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com