Zero reference adjusting device

A zero-position reference and adjustment device technology, applied in cable installation devices, cable installation, equipment for dismantling/armored cables, etc., can solve the problems of cumbersome adjustment process, affecting cable stripping efficiency, etc., to improve the convenience of use 、Ensure the effect of normal zero reference correction function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] For ease of understanding, combined here Figure 1-19 , the specific application structure and working method of the present invention are further described as follows:

[0065] The present invention can be applied to a stripper for stripping cables, such as a manually-adjustable stripper or even an automatic stripper. The following is a specific embodiment with the automatic peeler, and the details are as follows:

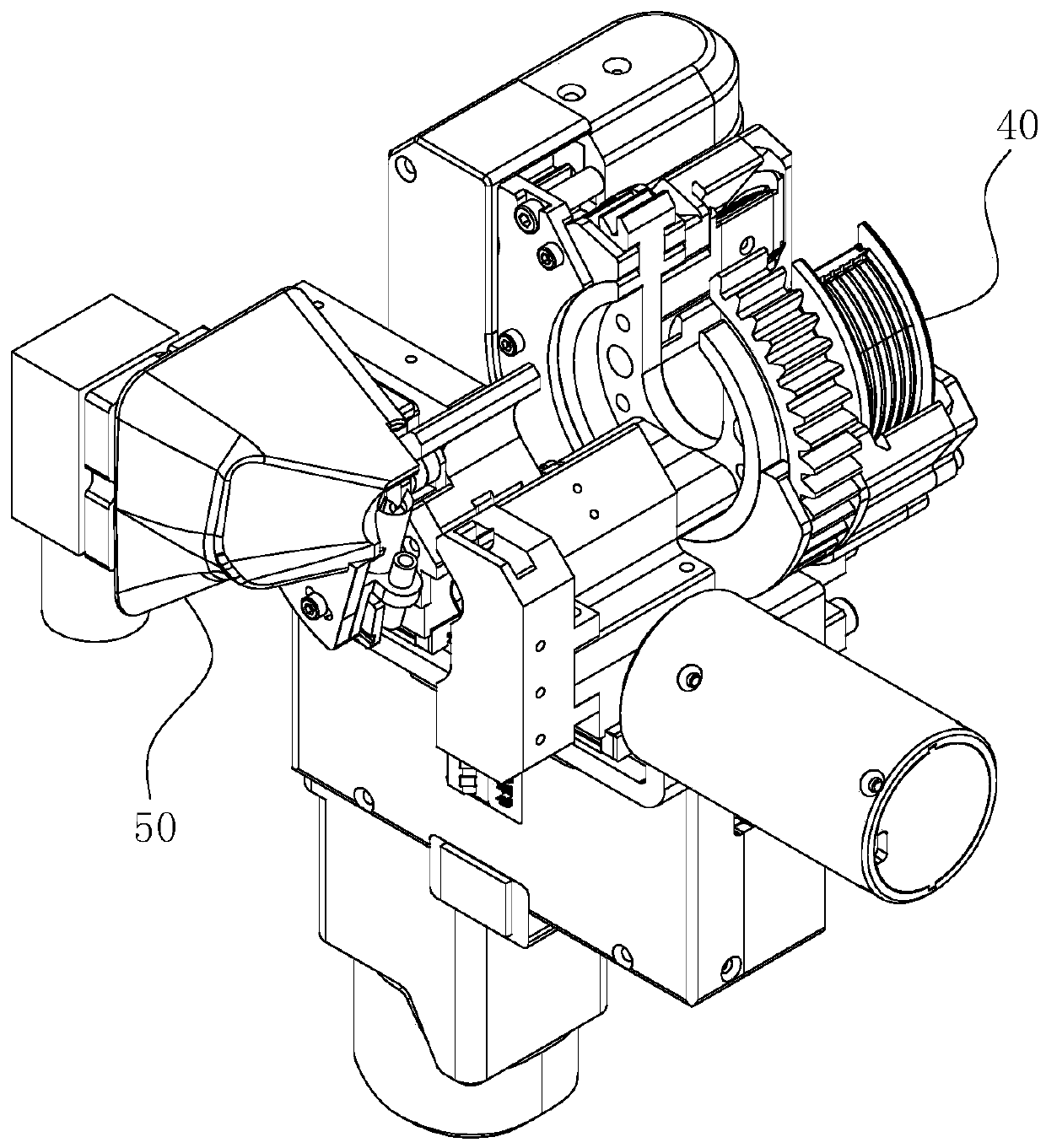

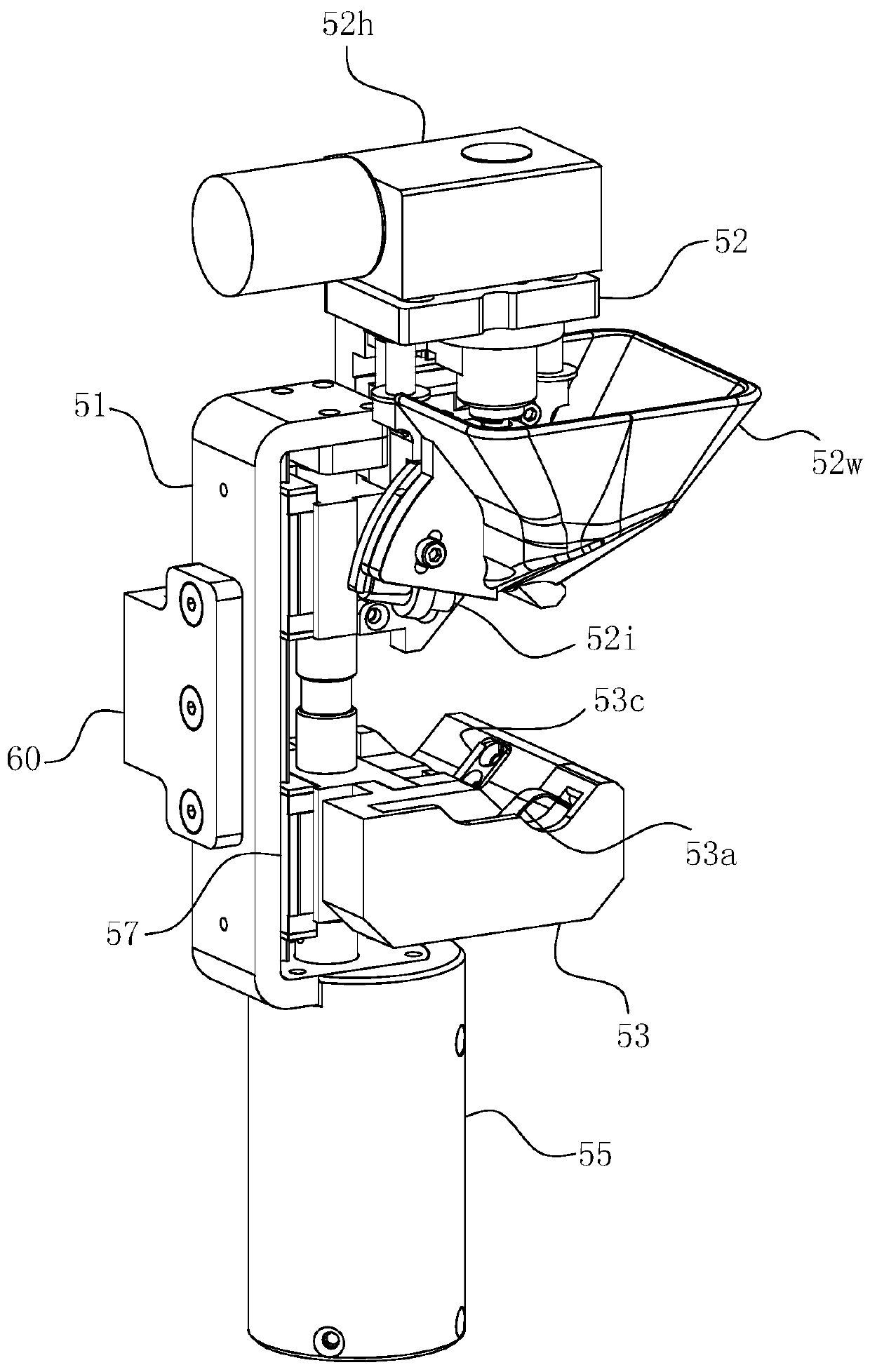

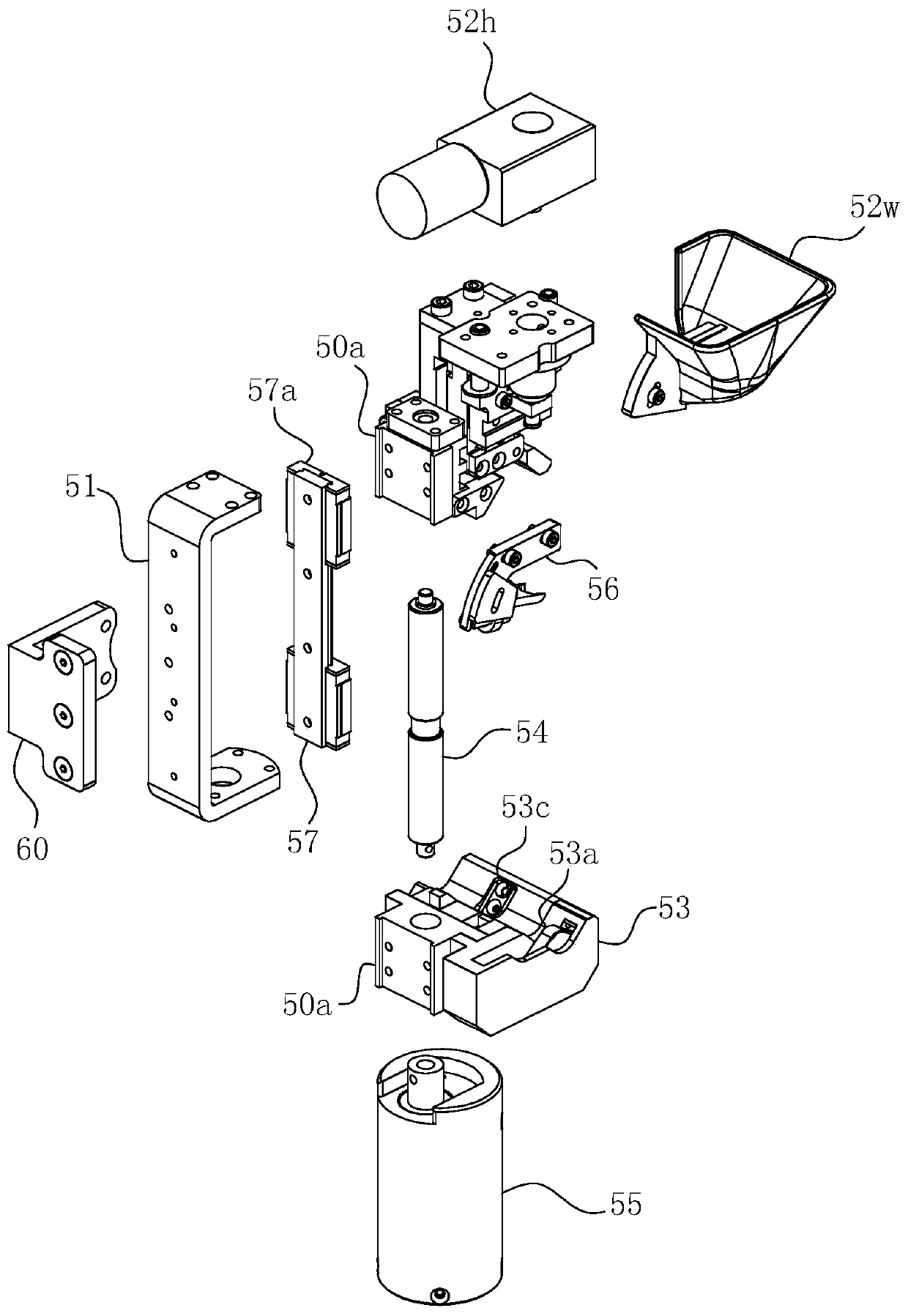

[0066] Such as figure 1 Shown automatic peeler, it is mainly made of peeling fixture 50 and drive unit 40 two parts; figure 2 The shown adapter frame 60 is fixed on the power shaft of the drive unit 40; and the drive unit 40 is then fixed on external devices such as an axial follower mount, a robot arm or even a hand-held insulating pole to realize the high-altitude cable Purpose of peeling operation. For the peeling jig 50, on the premise of including the zero reference adjustment assembly of the present invention, it also includes the jig opening adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com