Dust-collector dust cup assembly convenient to clean and dust collector

A technology of vacuum cleaners and dust cups, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., which can solve the problems of inconvenient and impossible cleaning, and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

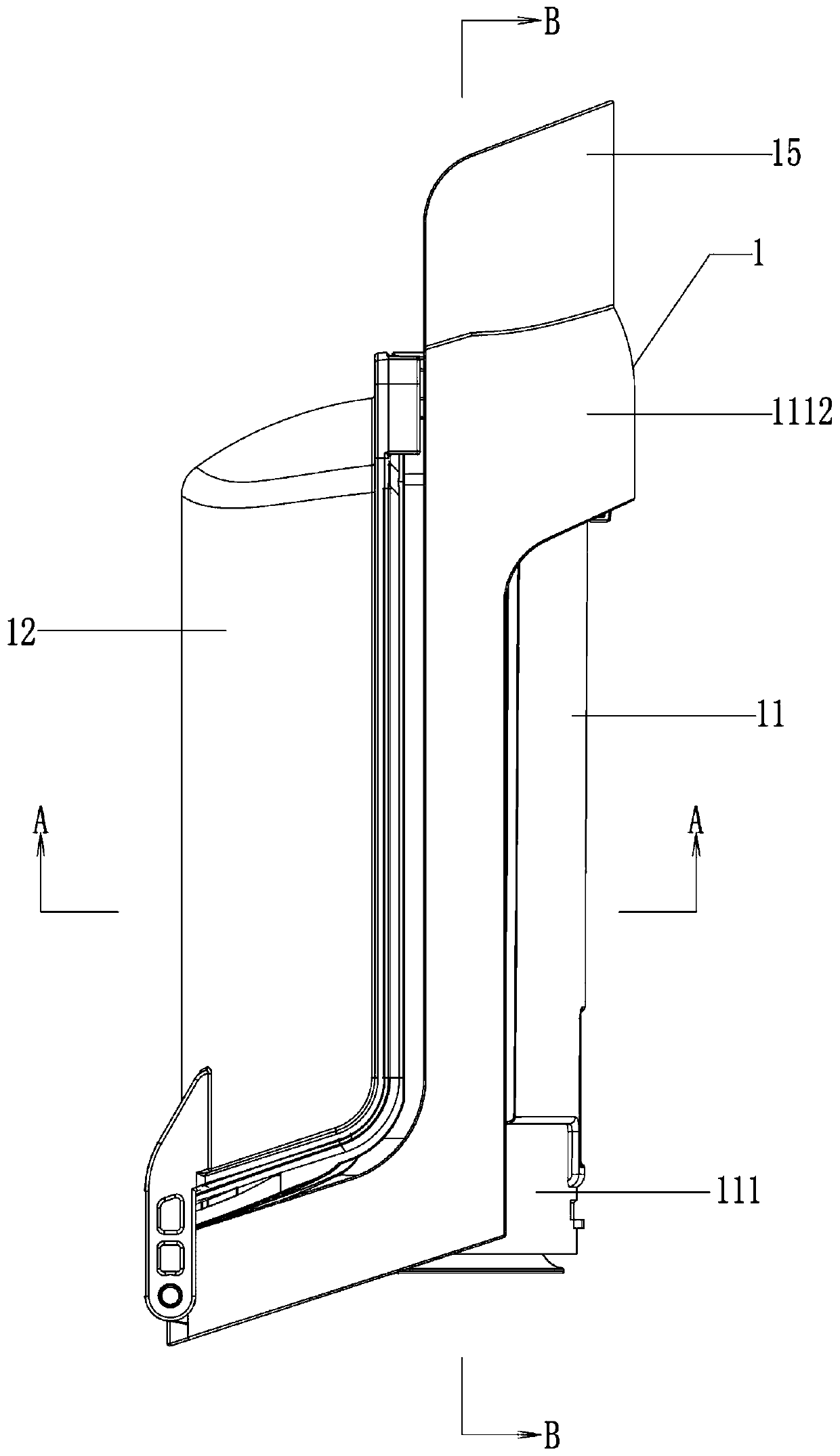

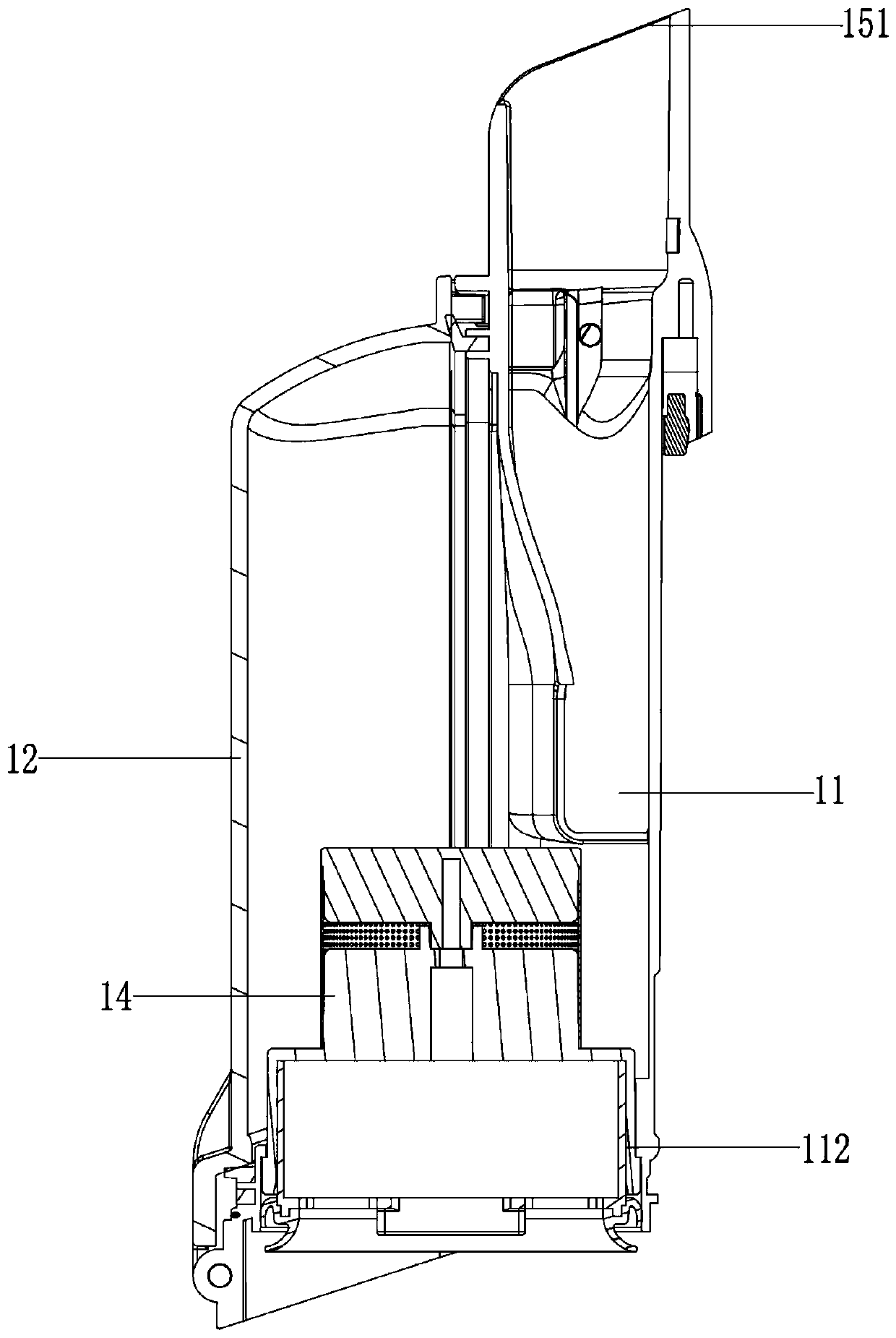

[0027] see Figure 1 to Figure 6 , the figure shows an easy-to-clean vacuum cleaner dust cup assembly provided by an embodiment of the present invention, which includes a dust cup 1, and the dust cup 1 uses any plane along its height direction as a dividing plane to divide the cup body 11 and A cup cover 12, the cup cover 12 is openably connected to the cup body 11, a sealing member 13 (specifically, a sealing strip) is arranged on the edge of the cup body 11, and the first end 111 of the cup body 11 is connected to the main unit 2 of the vacuum cleaner , the first end 111 is provided with an assembly hole 112, and a filter member 14 (that is, a Hypa commonly used in vacuum cleaners, the structure of which will not be described in detail here) is detachably installed in the assembly hole 112.

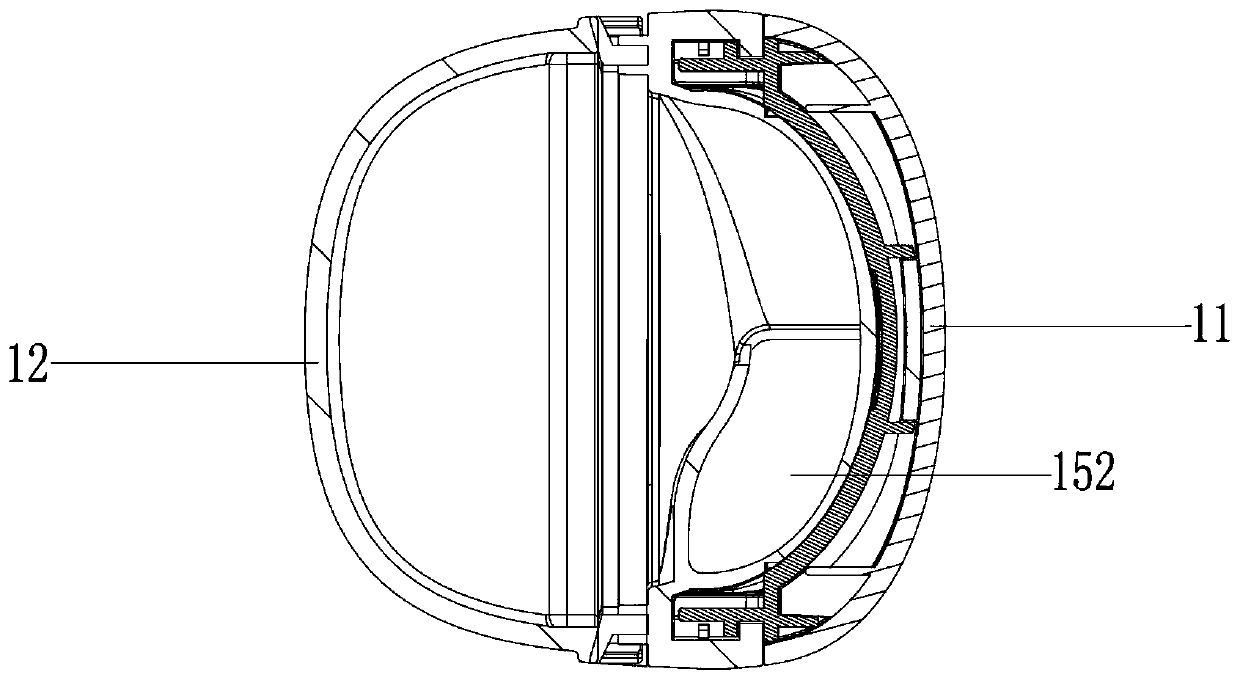

[0028] see Figure 1 to Figure 6 Specifically, the dust cup 1 is an elliptical cylinder as a whole, the cup body 11 occupies three sides of the dust cup 1, and the cup cover 12 occupie...

Embodiment 2

[0034] see Figure 1 to Figure 6 , the figure shows an easy-to-clean vacuum cleaner dust cup assembly and vacuum cleaner provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the cup body 11 is also integrated with an air duct 15; specifically, the air inlet 151 of the air duct 15 is located on the second end 1112 of the cup body 11 opposite to the first end 111, and the air outlet 152 of the air duct 15 extends toward the inside of the cup body 11. Through the setting of the above structure, the air duct is directly integrated on the dust cup, and the air flow no longer needs to pass through the main unit and then enter the dust cup, which can effectively increase the speed of the air flow entering the dust cup and help to improve the cleaning efficiency.

Embodiment 3

[0036] see Figure 1 to Figure 6 , the figure shows an easy-to-clean vacuum cleaner dust cup assembly and vacuum cleaner provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: first A bent end 1111 is formed on the end 111 , and a V-shaped structure is formed between the first end 111 and the bent end 1111 . Through the setting of the above structure, the opening area of the cup cover can be effectively enlarged, which is more convenient for the user, and also convenient for directly dumping the dust outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com