Pollution-free hs aerogel thermal insulation waterproof flame retardant material and preparation method thereof

A technology of thermal insulation and flame retardant materials, which is applied in the field of thermal insulation, thermal insulation and flame retardant, can solve the problems of water failure, poor connectivity of substrates, backward material properties, etc., and achieve the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

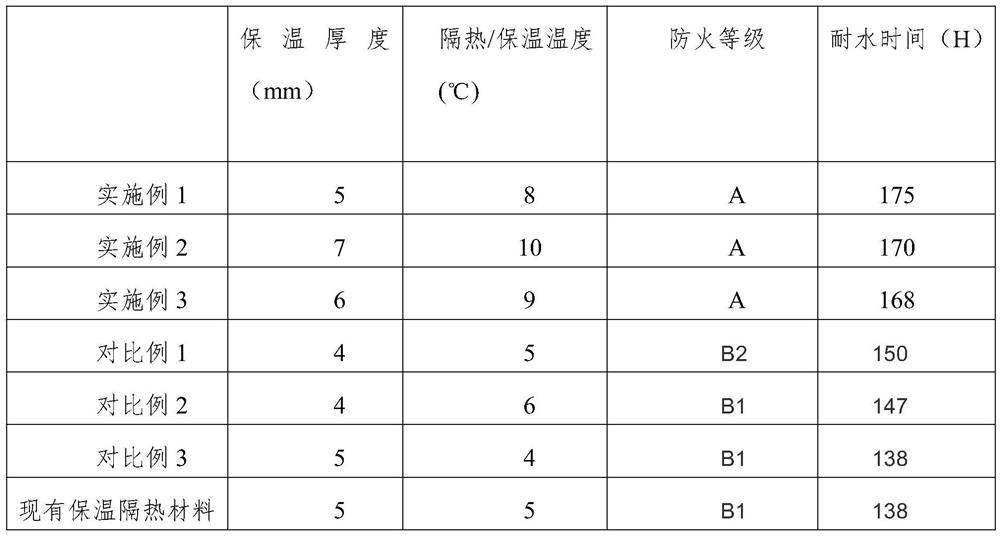

Examples

Embodiment 1

[0031] Pollution-free HS airgel thermal insulation waterproof flame retardant material, composed of airgel, hollow glass beads, calcium powder, silicon charcoal powder, perlite powder, attapulgite powder, cellulose, starch ether, glass fiber, light oxidation Composed of aluminum, white carbon black and adhesive, wherein the mass parts ratio of each component is as follows:

[0032] 4 parts of airgel, 4 parts of hollow glass microspheres, 19 parts of calcium powder, 19 parts of silicon charcoal powder, 6 parts of perlite powder, 14 parts of attapulgite powder, 4 parts of cellulose, 2 parts of starch ether, 9 parts of glass fiber , 9 parts of light alumina, 0.9 parts of white carbon black, 0.9 parts of adhesive,

[0033] The true density of the hollow glass microspheres is 0.20-0.60g / cm 3 , the particle size is between 2-125 microns,

[0034] The preparation method of the non-polluting HS airgel thermal insulation waterproof flame retardant material includes the following step...

Embodiment 2

[0042] Pollution-free HS airgel thermal insulation waterproof flame retardant material, composed of airgel, hollow glass beads, calcium powder, silicon charcoal powder, perlite powder, attapulgite powder, cellulose, starch ether, glass fiber, light oxidation Composed of aluminum, white carbon black and adhesive, wherein the mass parts ratio of each component is as follows:

[0043] Airgel 5 parts, hollow glass microspheres 5 parts, calcium powder 20 parts, silicon charcoal powder 20 parts, perlite powder 7 parts, attapulgite powder 15 parts, cellulose 5 parts, starch ether 3 parts, glass fiber 10 parts , 10 parts of light alumina, 1 part of white carbon black, 1 part of adhesive,

[0044] The true density of the hollow glass microspheres is 0.20-0.60g / cm 3 , the particle size is between 2-125 microns,

[0045] The preparation method of the non-polluting HS airgel thermal insulation waterproof flame retardant material includes the following steps:

[0046] (1) Weigh componen...

Embodiment 3

[0053] Pollution-free HS airgel thermal insulation waterproof flame retardant material, composed of airgel, hollow glass beads, calcium powder, silicon charcoal powder, perlite powder, attapulgite powder, cellulose, starch ether, glass fiber, light oxidation Composed of aluminum, white carbon black and adhesive, wherein the mass parts ratio of each component is as follows:

[0054] Airgel 5 parts, hollow glass microspheres 6 parts, calcium powder 21 parts, silicon charcoal powder 21 parts, perlite powder 8 parts, attapulgite powder 16 parts, cellulose 6 parts, starch ether 4 parts, glass fiber 11 parts , 11 parts of light alumina, 1.1 parts of white carbon black, 1.1 parts of adhesive,

[0055] The true density of the hollow glass microspheres is 0.20-0.60g / cm 3 , the particle size is between 2-125 microns,

[0056] The preparation method of the non-polluting HS airgel thermal insulation waterproof flame retardant material includes the following steps:

[0057] (1) Weigh co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com