Environment-friendly building material and preparation method thereof

A kind of building materials, green and environmental protection technology, applied in the field of building materials, to achieve the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

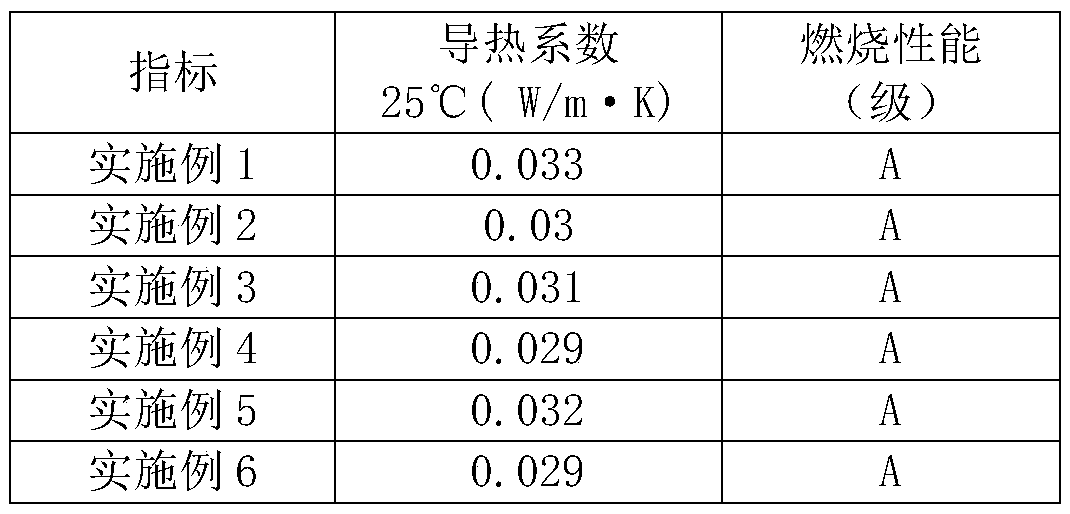

Examples

Embodiment 1

[0026] A green and environmentally friendly building material, characterized in that it is made of the following raw materials in parts by weight: 70 parts of silicon acrylic emulsion, 3 parts of zirconia, 27 parts of nano silicon dioxide, 33 parts of lithium borate, and 7 parts of hollow glass microspheres , 9 parts of wood fiber, 3 parts of dispersant, 292 parts of filler, 13 parts of humectant, 500 parts of neutral water.

[0027] The filler is composed of the following raw materials in parts by weight: 80 parts of aggregate shell powder, 120 parts of fly ash, 5 parts of mica powder, 7 parts of vermiculite, and 80 parts of desulfurized gypsum powder.

[0028] The silicone acrylic emulsion is silicone polyacrylic acid emulsion.

[0029] The dispersant is an aqueous dispersant sodium polyacrylate.

[0030] Described humectant is alcohol sub-12.

[0031] The preparation method of a green and environment-friendly building material specifically includes the following steps.

...

Embodiment 2

[0038] A green and environmentally friendly building material, characterized in that it is made of the following raw materials in parts by weight: 75 parts of silicon acrylic emulsion, 4 parts of zirconia, 28 parts of nano silicon dioxide, 34 parts of lithium borate, and 8 parts of hollow glass microspheres , 9 parts of wood fiber, 3 parts of dispersant, 293 parts of filler, 14 parts of humectant, 500 parts of neutral water.

[0039] The filler is composed of the following raw materials in parts by weight: 80 parts of aggregate shell powder, 120 parts of fly ash, 5 parts of mica powder, 7 parts of vermiculite, and 80 parts of desulfurized gypsum powder.

[0040] The silicone acrylic emulsion is silicone polyacrylic acid emulsion.

[0041] The dispersant is water-based sodium polyacrylate.

[0042] Described humectant is alcohol sub-12.

[0043] The preparation method of a green and environment-friendly building material specifically includes the following steps.

[0044] (1...

Embodiment 3

[0050] A green environmental protection building material is characterized in that it is made of the following raw materials in parts by weight: 80 parts of silicon acrylic emulsion, 5 parts of zirconia, 29 parts of nano silicon dioxide, 35 parts of lithium borate, and 9 parts of hollow glass microspheres , 10 parts of wood fiber, 4 parts of dispersant, 295 parts of filler, 15 parts of humectant, 500 parts of neutral water.

[0051] The filler is composed of the following raw materials in parts by weight: 80 parts of aggregate shell powder, 120 parts of fly ash, 5 parts of mica powder, 7 parts of vermiculite, and 80 parts of desulfurized gypsum powder.

[0052] The silicone acrylic emulsion is silicone polyacrylic acid emulsion.

[0053] The dispersant is an aqueous water-based dispersant sodium polyacrylate.

[0054] Described humectant is alcohol sub-12.

[0055] The preparation method of a green and environment-friendly building material specifically includes the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com