Protracted pile frame platform

A technology of stretching and pile frame, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of increasing the cost of turning, increasing the difficulty and cost of transshipment, and the external dimension of the pile driver platform cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

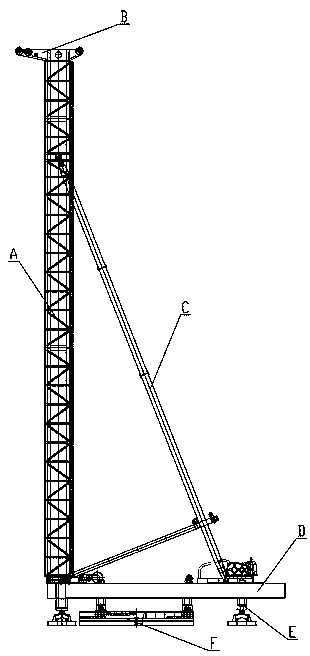

[0020] figure 1 Shown is the existing common walking mobile pile frame structure, the pile frame includes a pile frame platform D, the pile frame platform D is a frame structure composed of longitudinal beams and beams fixedly connected to each other, the longitudinal beams and beams It is welded by section steel or steel plate. A column A is installed on the upper plane of the pile frame platform D, a pulley frame B is arranged on the top of the column A, and a brace is connected between the upper plane of the pile frame platform D and the column A. Rod C, platform leg E is installed on the lower plane of the pile frame platform D, the platform leg E is a hydraulic cylinder, the cylinder body of the hydraulic cylinder is fixedly installed on the pile frame platform D, and the protruding end of the piston rod of the hydraulic cylinder Hinged on the walking chassis F, the walking movement of the entire platform can be realized through the alternate expansion and contraction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com