Single-converter double-steel smelting technology for BOF converter

A technology of steel smelting and converter blowing, which is applied in the field of BOF single-furnace double-steel smelting technology, can solve the problems of reducing the amount of slag in the ladle, the low hit rate, and reducing the rate of phosphorus return, so as to reduce the production cost of steelmaking, Improve the hit rate and reduce the effect of peroxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

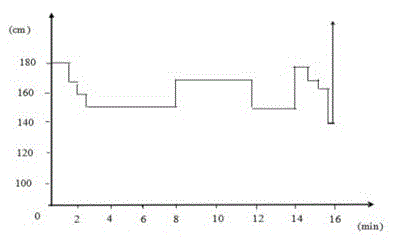

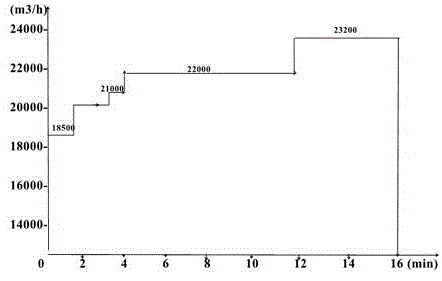

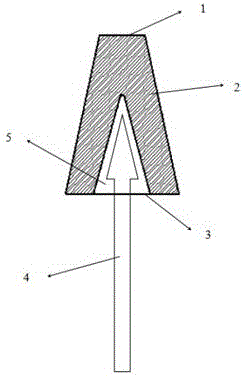

[0024] 1. The technical parameters of the converter tilting motor unit are that the rated current of the motor is 50HZ, and the speed is 589r / min. When it is put into production, the execution current of the motor is 38HZ. At the end of the first ladle tapping of the converter, because there was still about 60 tons of molten steel in the furnace, the slag blocking operation could not be carried out. It was determined that the running time in the 36° interval of the furnace return (-92° to -56°) was 6s. Due to the current motor operating parameters, the tilting speed of the furnace body is not particularly ideal, resulting in a large amount of slag in the first ladle, resulting in a high rate of phosphorus return to the ladle. From 2014 to 2015, due to the large amount of slag in the first tapping of the converter, the transfer of molten steel The phosphorus composition of the finished steel products in large quantities is inconsistent. In order to reduce the amount of slag fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com