Method for evaluating heat release of lithium ion battery

A technology of lithium-ion battery and heat release, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of long time consumption, change of authenticity, slow temperature rise, etc., to reduce material costs and improve cost-effectiveness ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

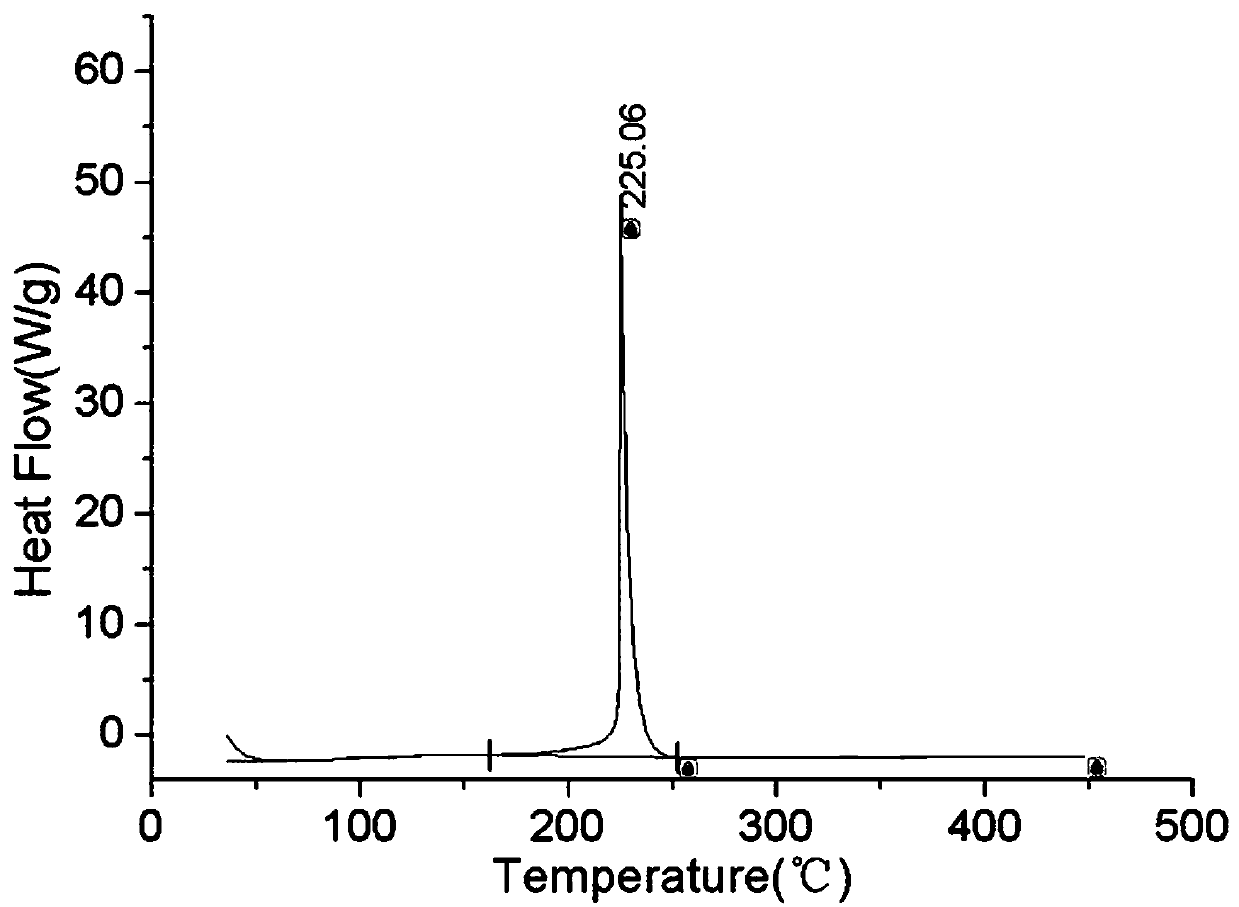

[0060] A method for evaluating the heat release of lithium-ion batteries, comprising the steps of:

[0061] S1. Provide a cylindrical 18650-2.8Ah lithium-ion battery, charge it with a constant current of 0.5C to 4.2V, and a constant voltage of 4.2V until the current is less than 30mA, and adjust the lithium-ion battery to a 100% SOC state;

[0062] S2. dismantling the adjusted lithium-ion battery to obtain the positive electrode sheet, negative electrode sheet and diaphragm;

[0063] S3. Wash the positive electrode sheet, negative electrode sheet and separator with DMC for 3 times, put them in a vacuum oven, and dry them in vacuum at 40°C for 12h;

[0064] S4. slice the above-mentioned positive electrode sheet and negative electrode sheet into circular electrode sheets with a diameter of 3mm, place the diaphragm between the sliced positive electrode sheet and the negative electrode sheet, put it into a high-pressure crucible, and inject the electrolyte, Assembled into a min...

Embodiment 2

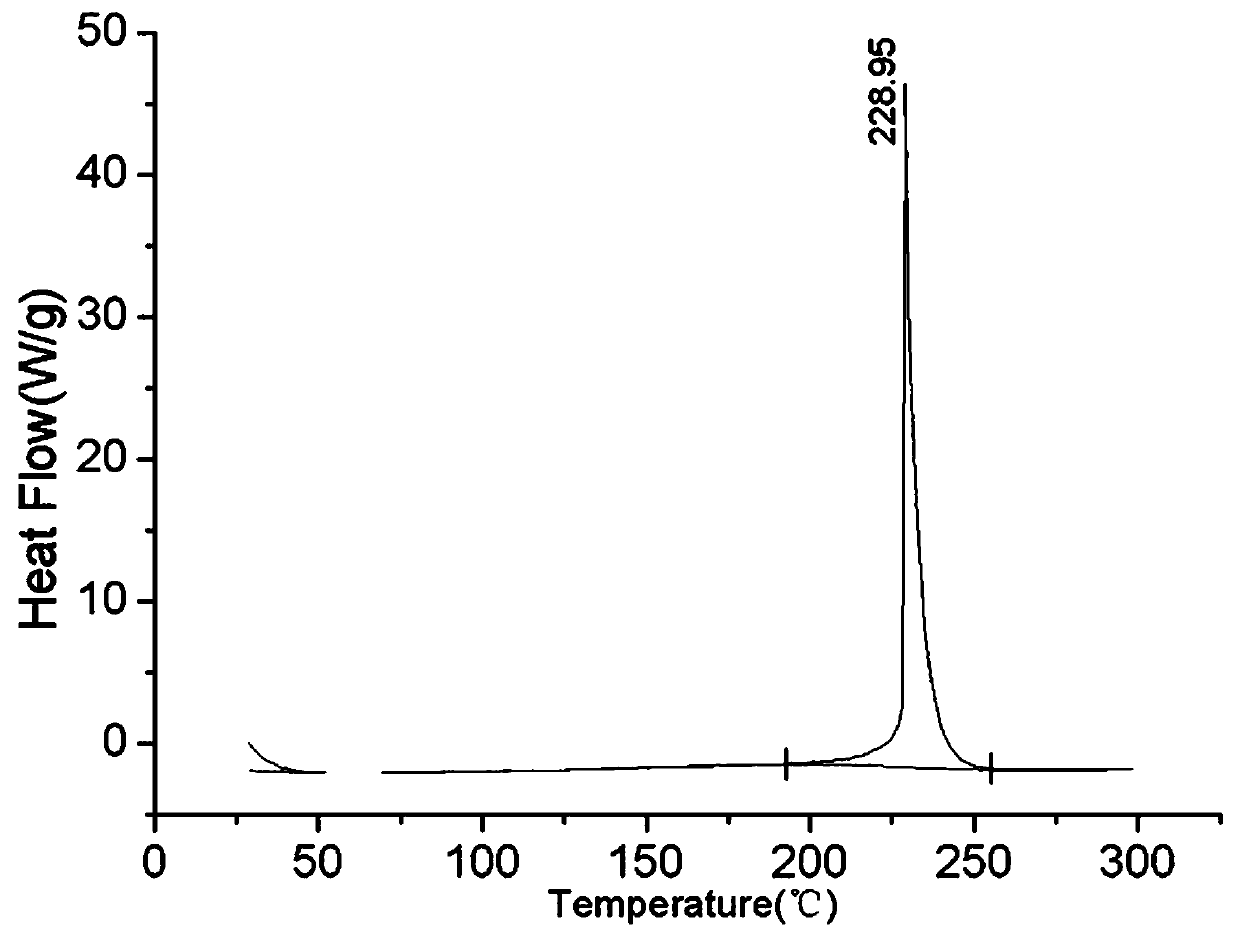

[0071] A method for evaluating the heat release of lithium-ion batteries, comprising the steps of:

[0072] S1. Provide a cylindrical 18650-2.75Ah lithium-ion battery, charge it with a constant current of 0.5C to 4.2V, and a constant voltage of 4.2V until the current is less than 27.5mA, and adjust the lithium-ion battery to a 100% SOC state;

[0073] S2. dismantling the adjusted lithium-ion battery to obtain the positive electrode sheet, negative electrode sheet and diaphragm;

[0074] S3. Wash the positive electrode sheet, negative electrode sheet and separator with DMC for 4 times, put them in a vacuum oven, and dry them in vacuum at 25°C for 12h;

[0075] S4. Slice the above-mentioned positive and negative electrodes into circular poles with a diameter of 2-3 mm, place the diaphragm between the sliced positive and negative electrodes, put it into a high-pressure crucible, and inject the electrolytic Liquid, assembled into a miniature full battery; wherein, in the steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com