Battery structure, battery and preparation method thereof

A battery and current technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as tilting of the transfer piece, increase the risk of breakage failure of the circuit breaker pin, and complicated switching process, so as to reduce the breakage The effect of the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the following embodiments may be combined with each other or partially replaced in any possible manner.

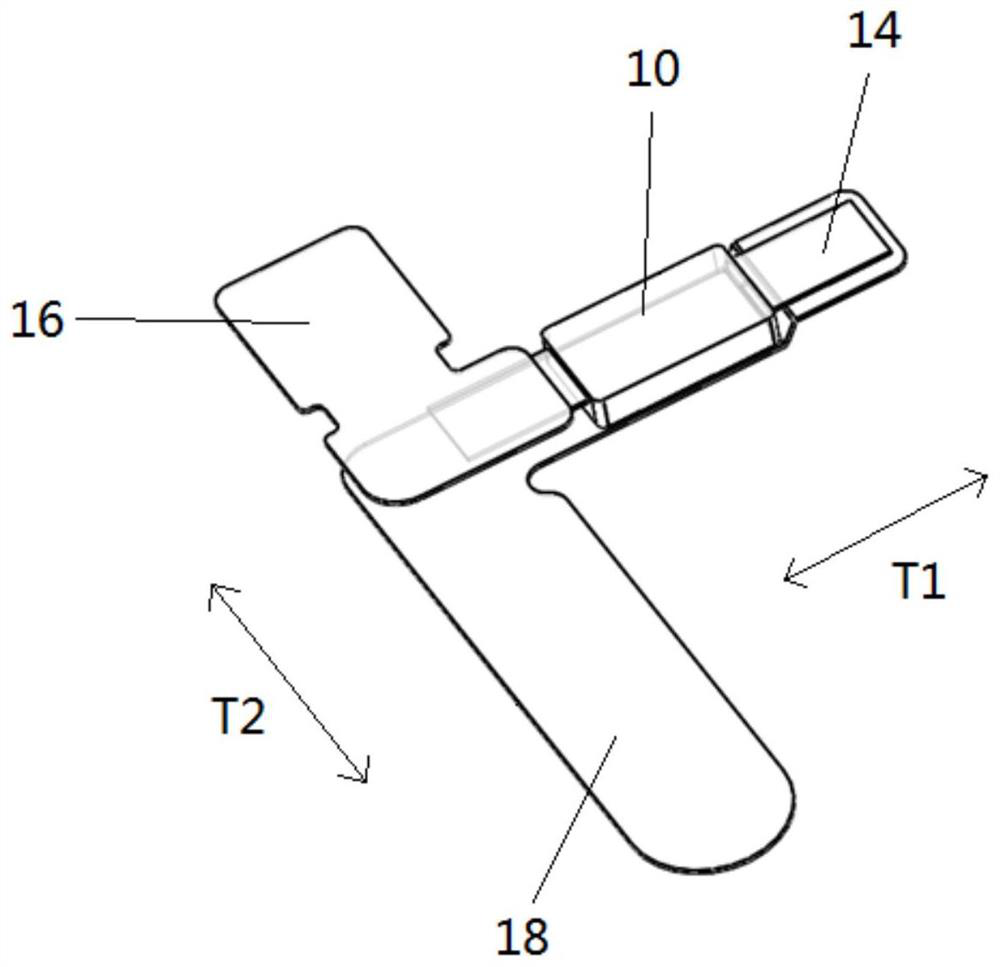

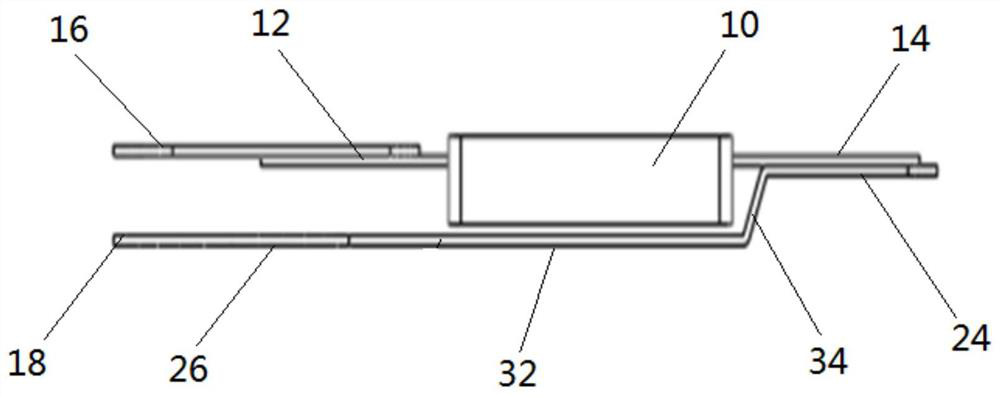

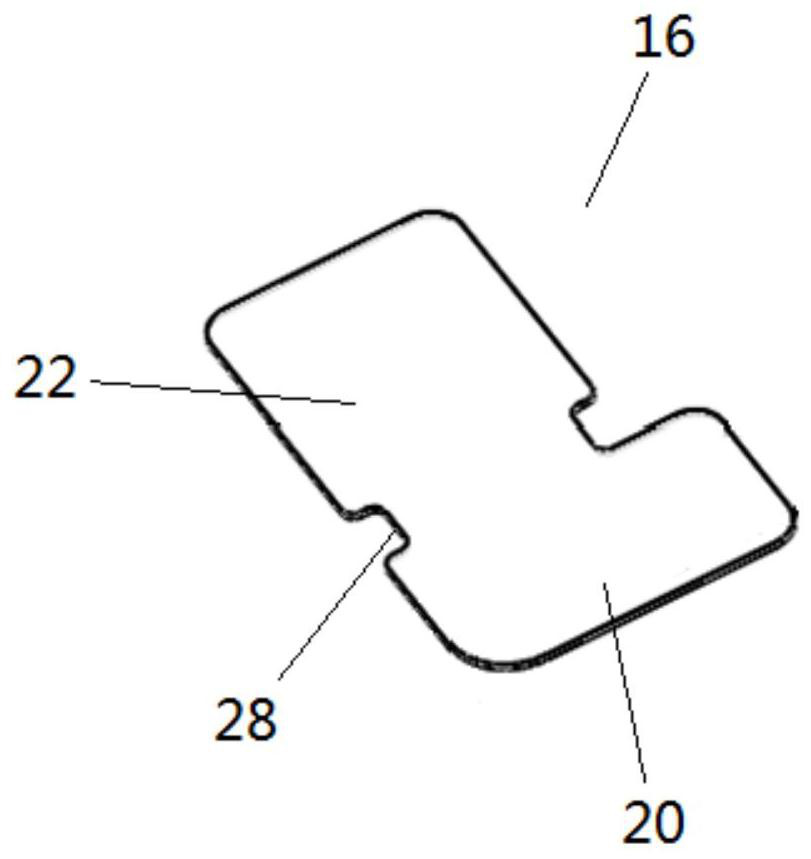

[0038] First refer to Figure 1 to Figure 4 , which shows a battery structure according to one embodiment of the present invention. As shown, the battery structure includes a circuit element 10, exemplarily, in one possible embodiment of the present invention, the circuit element 10 includes a circuit breaker. like figure 1 and figure 2 As shown, the circuit element 10 is provided with a first contact 12 and a second contact 14 extending in a first direction T1 , wherein the first contact 12 and the second contact 14 are exposed sections of the body of the circuit element 10 Also referred to herein as pins of the circuit element 10 , the transition piece 16 and the turn-out piece 18 are coupled to the first contact 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com