Experimental device for simulating single-joint dynamic variable load variable inertia of an industrial robot

A technology for industrial robots and experimental devices, applied in manipulators, manufacturing tools, etc., can solve the problems of complex structure, difficult control, and difficult to realize dynamic change of inertia, and achieve the effects of easy adjustment, convenient installation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

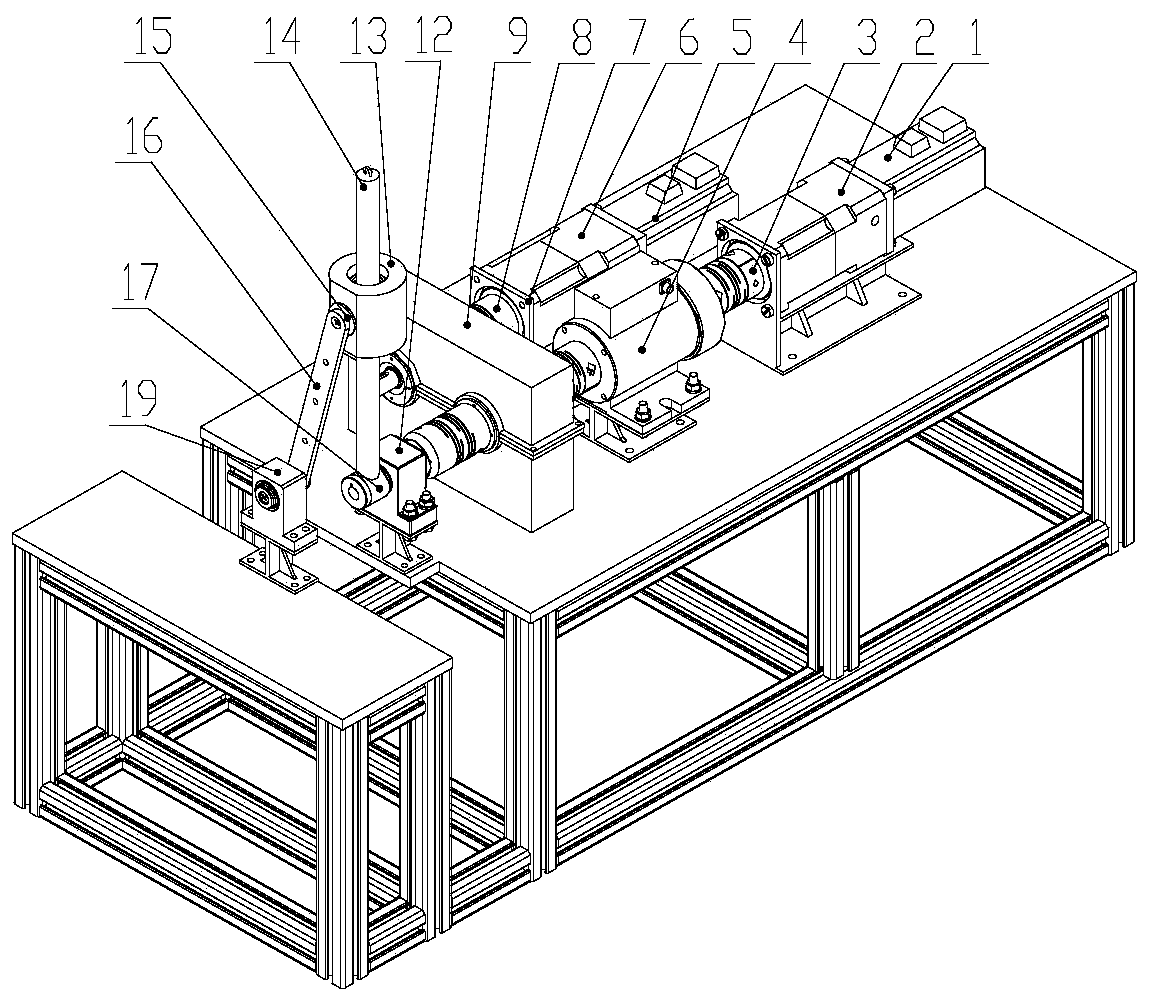

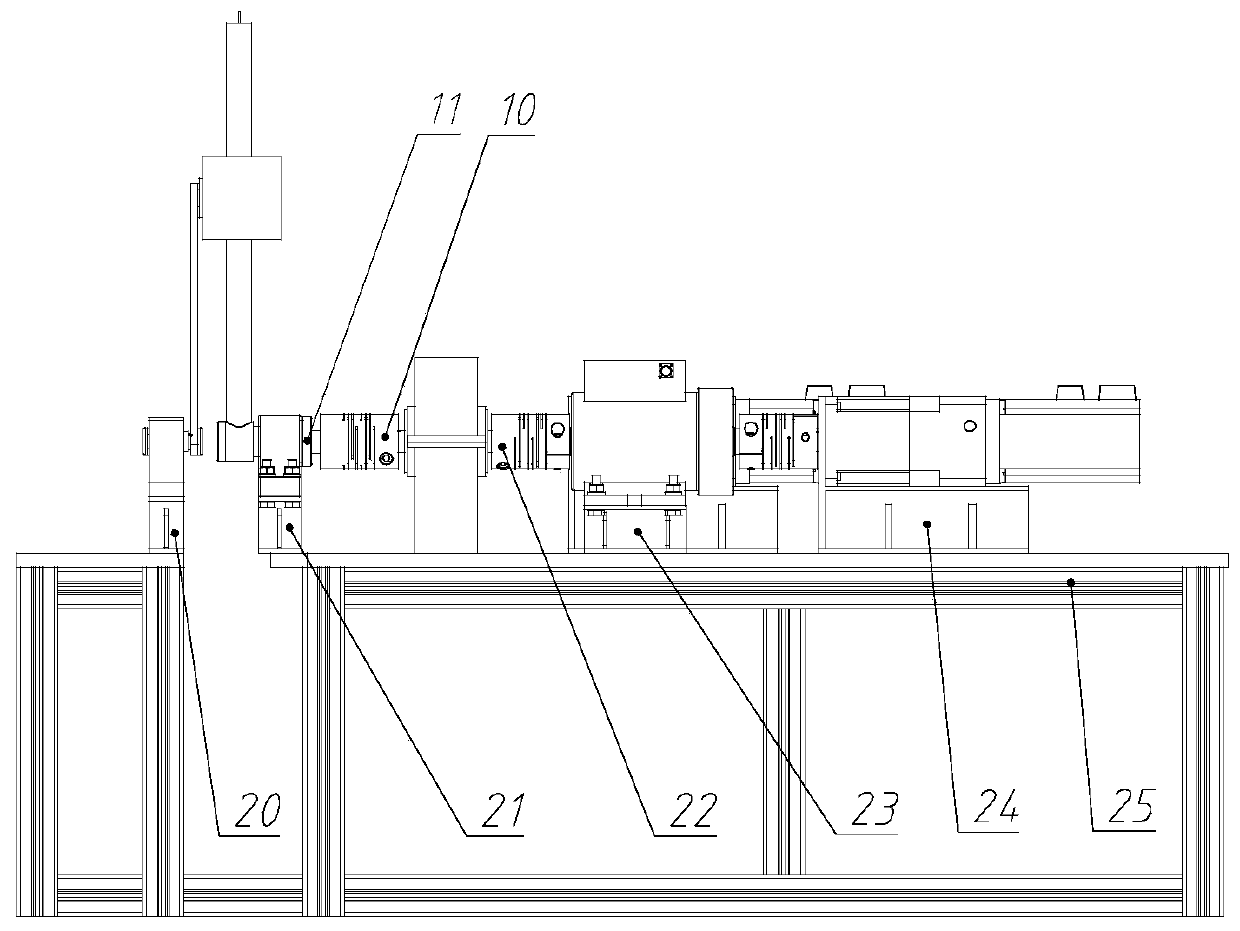

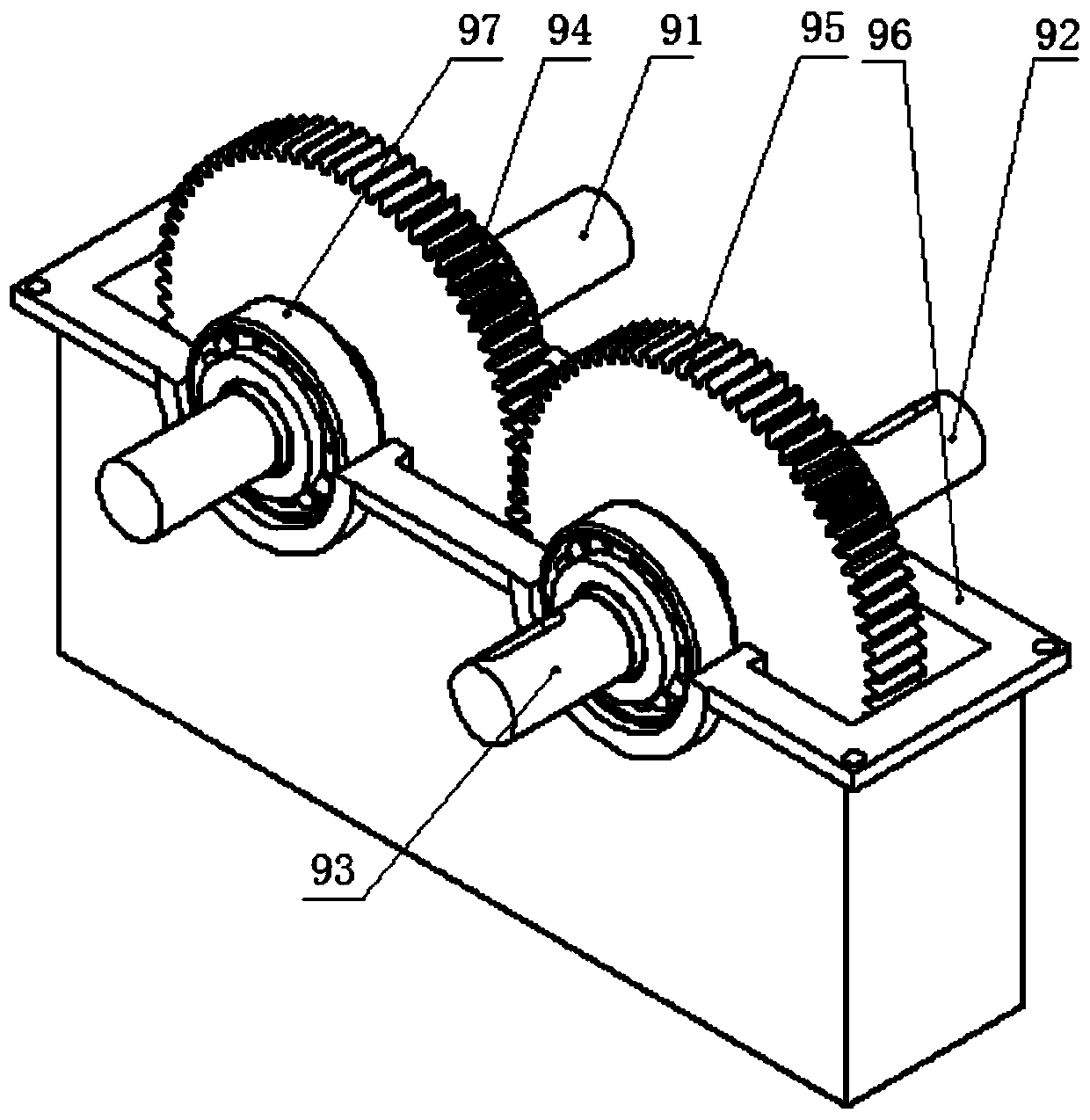

[0038] The present invention will be further described below in conjunction with accompanying drawing:

[0039] like Figure 1-10 As shown, an experimental device for simulating the dynamic variable load and variable inertia of industrial robot joints, the first frame 25, the second frame 26, the first input servo motor 1, the first reducer 2, the first coupling 3, Dynamic torque sensor 4, gear transmission box 9, second coupling 22, angle sensor 11, first double bearing housing 12, variable inertia lever arm 14, third coupling 10, rotating shaft 17, second input servo motor 5 , the second reducer 6, the fourth coupling 8, the mass slider 13, the swing arm 16, the second double bearing housing 19, the rotating shaft 18, the first support base 21, the second support base 23, the third support base 24. The fourth support base 7 and the fifth support base 20.

[0040] Both the first input servo motor 1 and the first reducer 2 are fixed on the third support base 24, and the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com