Rotating body reflecting film posting device

A technology of a reflective film and a rotating body is applied in the field of reflective film sticking devices for rotating bodies, which can solve the problems of difficult reflective film sticking, etc., and achieve the effects of short time consumption, labor-saving work process and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The rotating body on the anti-collision guardrail is generally set as a cylinder, and at least one groove is opened on the cylinder. Reflective film needs to be posted in the groove.

[0042] At present, the company mainly produces three types of rotating bodies, which are concentric rings with grooves on the outer diameter. The first type has an inner diameter of 140±100mm, an outer diameter of 220±10mm and a height of 480mm; the second type has an inner diameter of 140±10mm, an outer diameter of 350±10mm and a height of 480mm; the third type has an inner diameter of 140±10mm and an outer diameter of 350±10mm , height 240mm.

[0043] In the process of pasting the reflective film of the rotating body, the rotating body needs to be sleeved on the device of the present application, and then the reflective film is pasted in the groove of the rotating body by rotating.

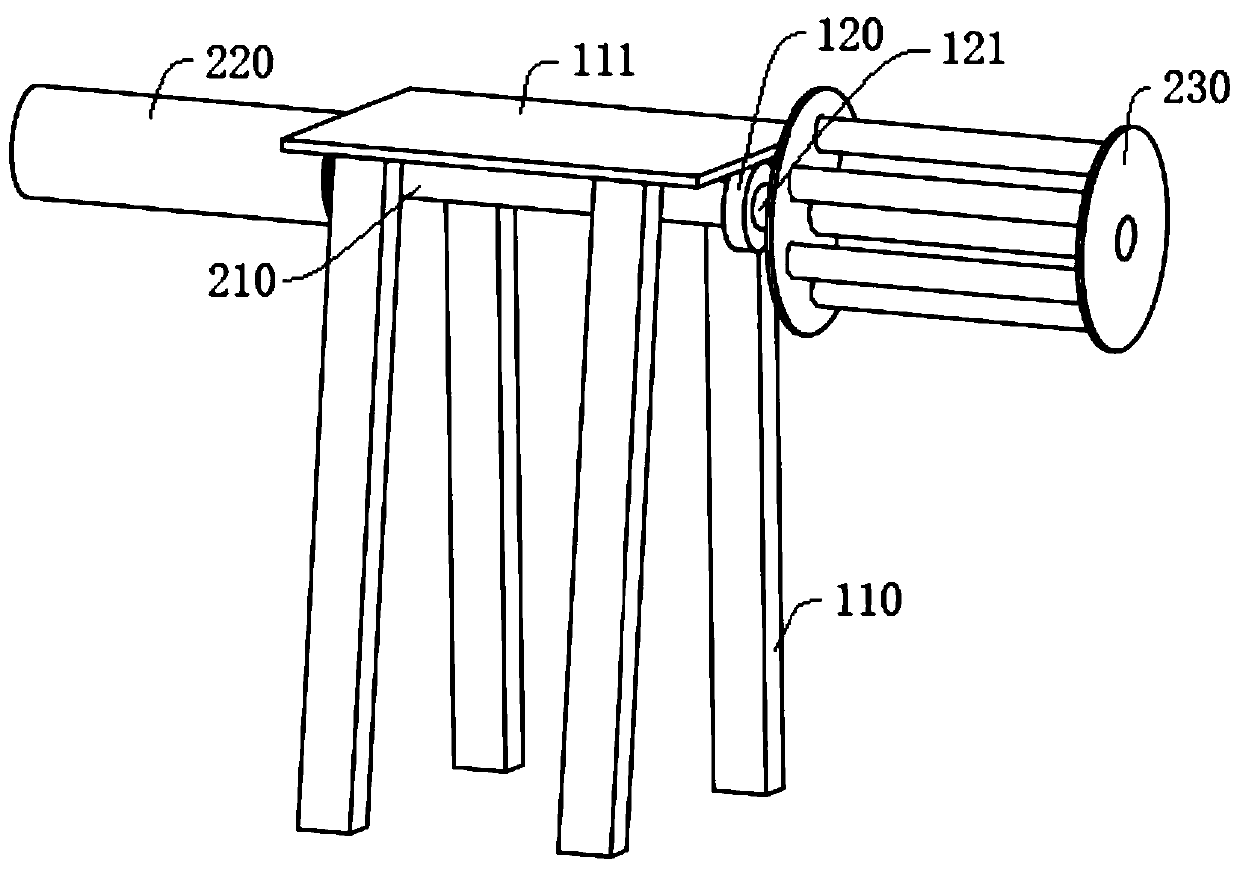

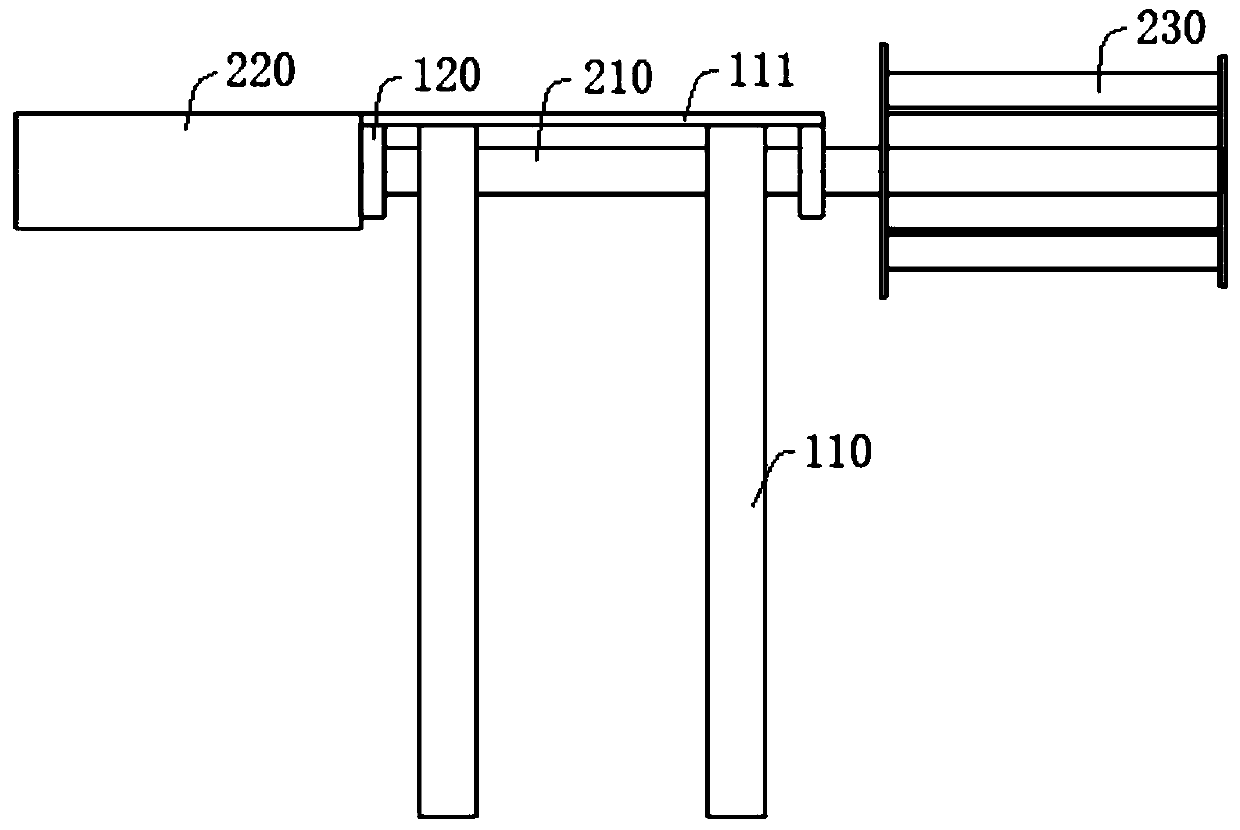

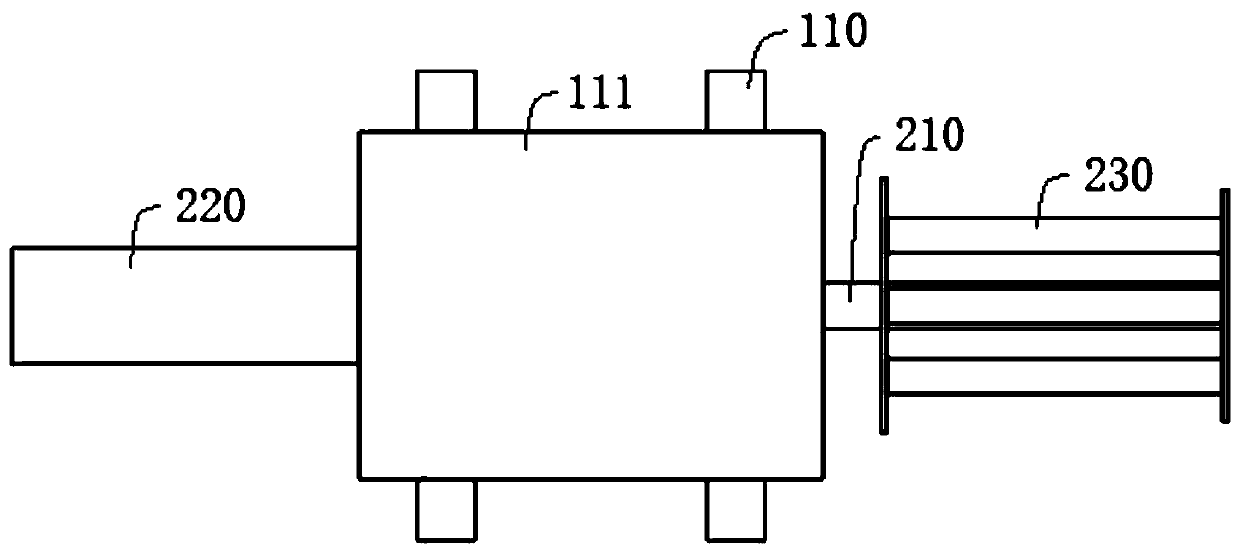

[0044] like Figure 1-Figure 3 As shown, a rotating body reflective film sticking device in this embo...

Embodiment 2

[0048] In actual use, large-scale operations are required, and when manual labor cannot meet the output requirements, the completely manual method is not suitable for production and improves production efficiency.

[0049] And because the size of the rotating body is different, the quality of the rotating body is also different. In order to adapt to different anti-collision guardrails, the size of the hollow in the middle of the rotating body will change. A rotating body is formed, so that the rotating body also rotates during the rotating process of the rotating roller 220. A second mounting hole 221 is opened on the surface of the rotating roller 220, and an adjusting assembly 400 is arranged in the second mounting hole 221. The elastic member 420 controls the height of the top pressing block 410, so that the top pressing block 410 fits the inner wall of the hollow center of the rotating body and presses the rotating body. And turn.

[0050] like Figure 4-6 As shown, a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com