Method for judging cleaning condition of secondary water supply and storage equipment

A technology for secondary water supply and equipment, which is used in complex mathematical operations, instruments, data processing applications, etc., and can solve problems such as judging the cleanliness of water storage equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0160] The invention provides a method for judging the cleanliness of secondary water supply and storage equipment, comprising the following steps:

[0161] Step 1: Calculating the sample attenuation coefficient for judgment analysis and the water temperature corresponding to the sample attenuation coefficient.

[0162]In this step, the sample attenuation coefficient refers to the attenuation coefficient of the tap water stored in the water storage equipment within the evaluation and analysis time period, which is characterized in that the outflow time used to calculate the attenuation coefficient is within the evaluation and analysis time period, and the evaluation and analysis time period is An artificially set period of time dedicated to judging and analyzing the cleanliness of water storage equipment; the sample attenuation coefficient is preferably calculated under the condition that tap water flows out of the water storage equipment in the order in which it flows into the...

Embodiment 2

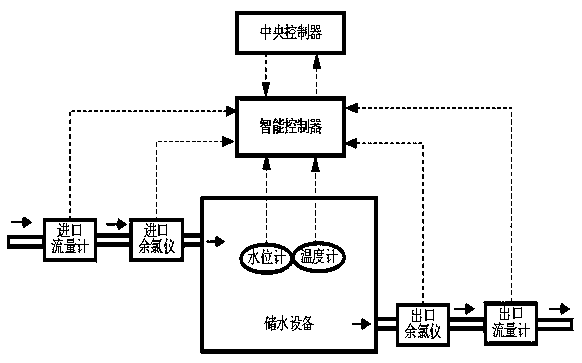

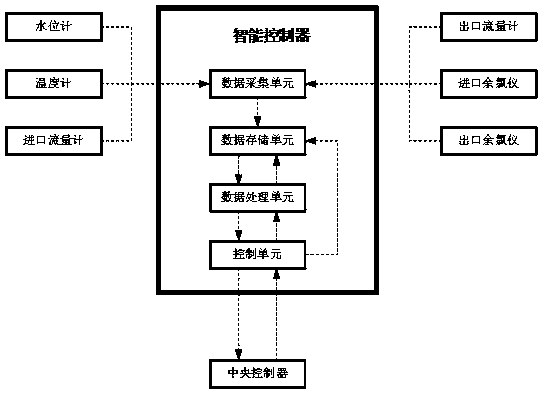

[0305] This embodiment is further described on the basis of embodiment 1 in conjunction with specific actual data, specifically: a stainless steel water tank with a volume of 33 cubic meters is selected as a secondary water supply and storage device in an industrial park, and its water intake passes through a float valve control, the specific structure is as figure 1 , 2 shown. Among them, the sample attenuation coefficient and cleaning attenuation coefficient involved in the judging process are all calculated under the condition that the tap water flows out of the water storage device in the order in which it flows into the water storage device. Under these conditions, the evaluation of the cleanliness of the secondary water supply and storage equipment includes the following steps:

[0306] Step 1: Calculating the sample attenuation coefficient for judgment analysis and the water temperature corresponding to the sample attenuation coefficient.

[0307] In this step, the c...

Embodiment 3

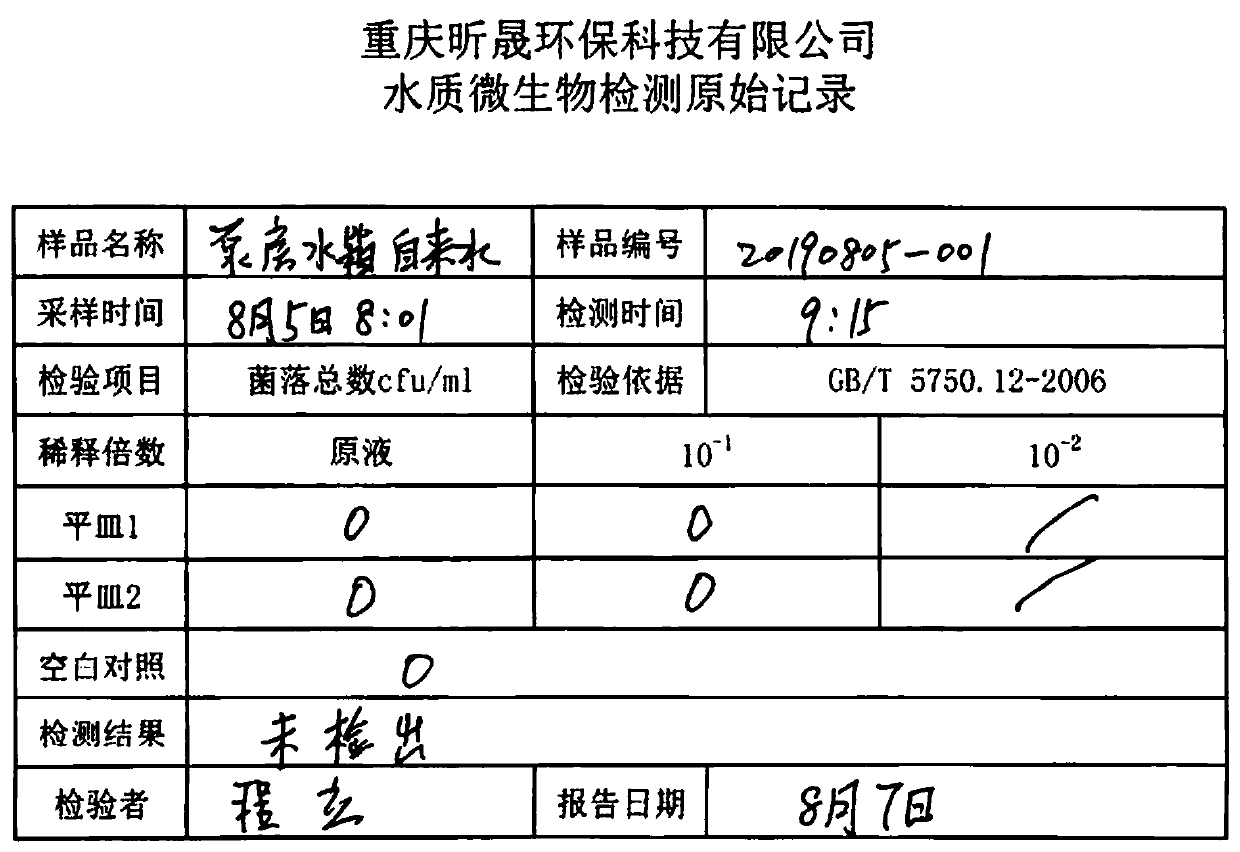

[0460] This embodiment is to verify the accuracy of the present invention by performing microbial detection on tap water in the judged water storage equipment on the basis of Example 2, specifically: a water storage equipment in an industrial park on August 4, 2019 Cleaning is completed and put into use at 18:40 on the same day. The management system for evaluating and analyzing the cleanliness of the water storage equipment in the present invention starts to run immediately. Samples are taken from the water storage equipment at 8:01 on August 5, 2019, and at 9:00 a.m. on the same day 15 The samples were inspected, the inspection item was the total number of bacterial colonies, and the inspection basis was GB / T5750.12-2006. On August 7, 2019, the inspection result was "not detected". The inspection results were as follows: image 3 As shown, it proves that the cleaning of the water storage equipment is effective; at 6:10 on August 11, 2019, the intelligent controller of the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com