Dust collector brush head and dust collection method

A technology for a vacuum cleaner and a brush head, applied in the field of vacuum cleaner brush heads and dust collection, can solve problems such as poor user experience, laborious cleaning for users, and easy entanglement of hair, etc., and achieve the effect of improving cleaning efficiency, improving cleaning effect, and cleaning a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

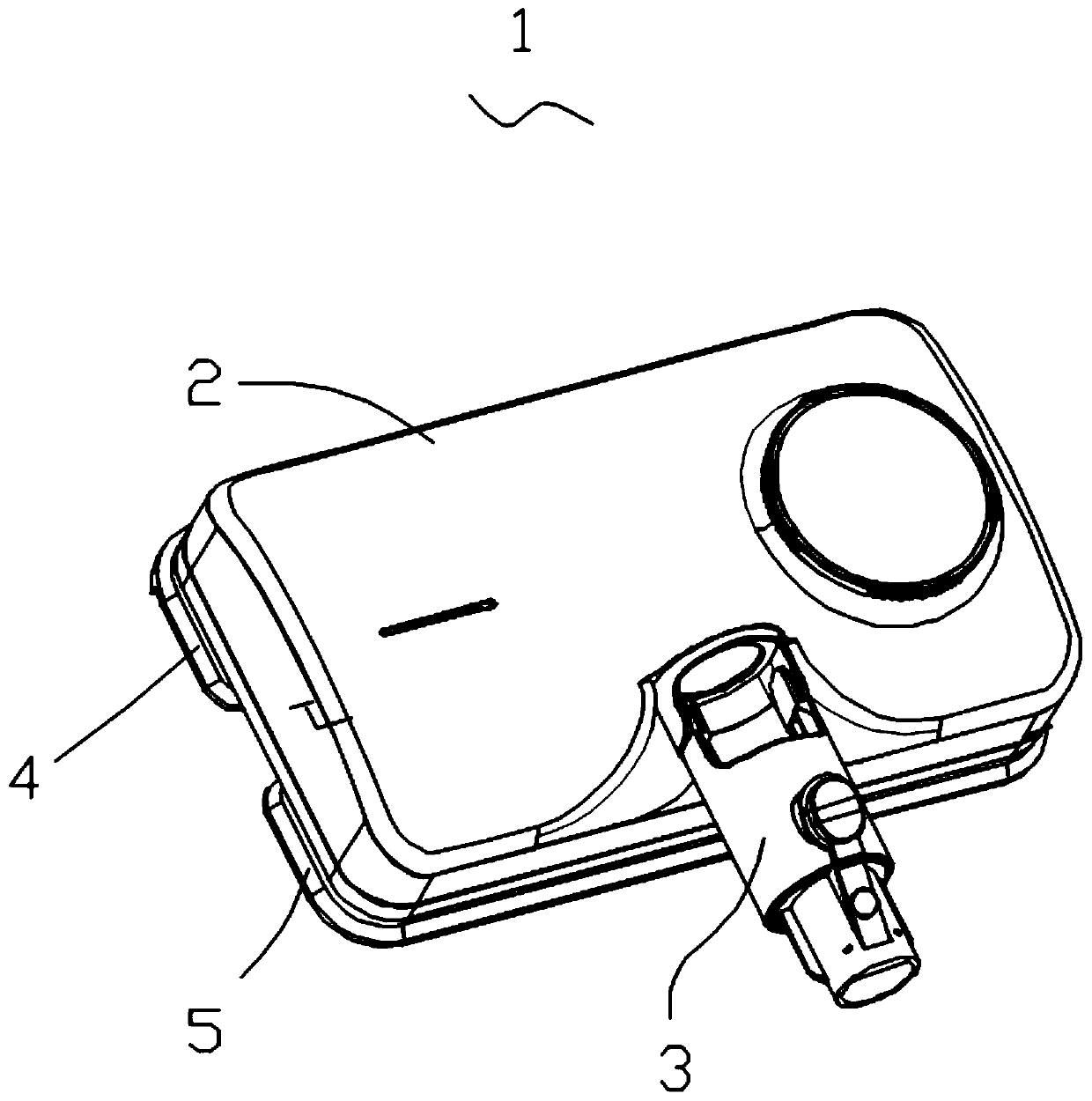

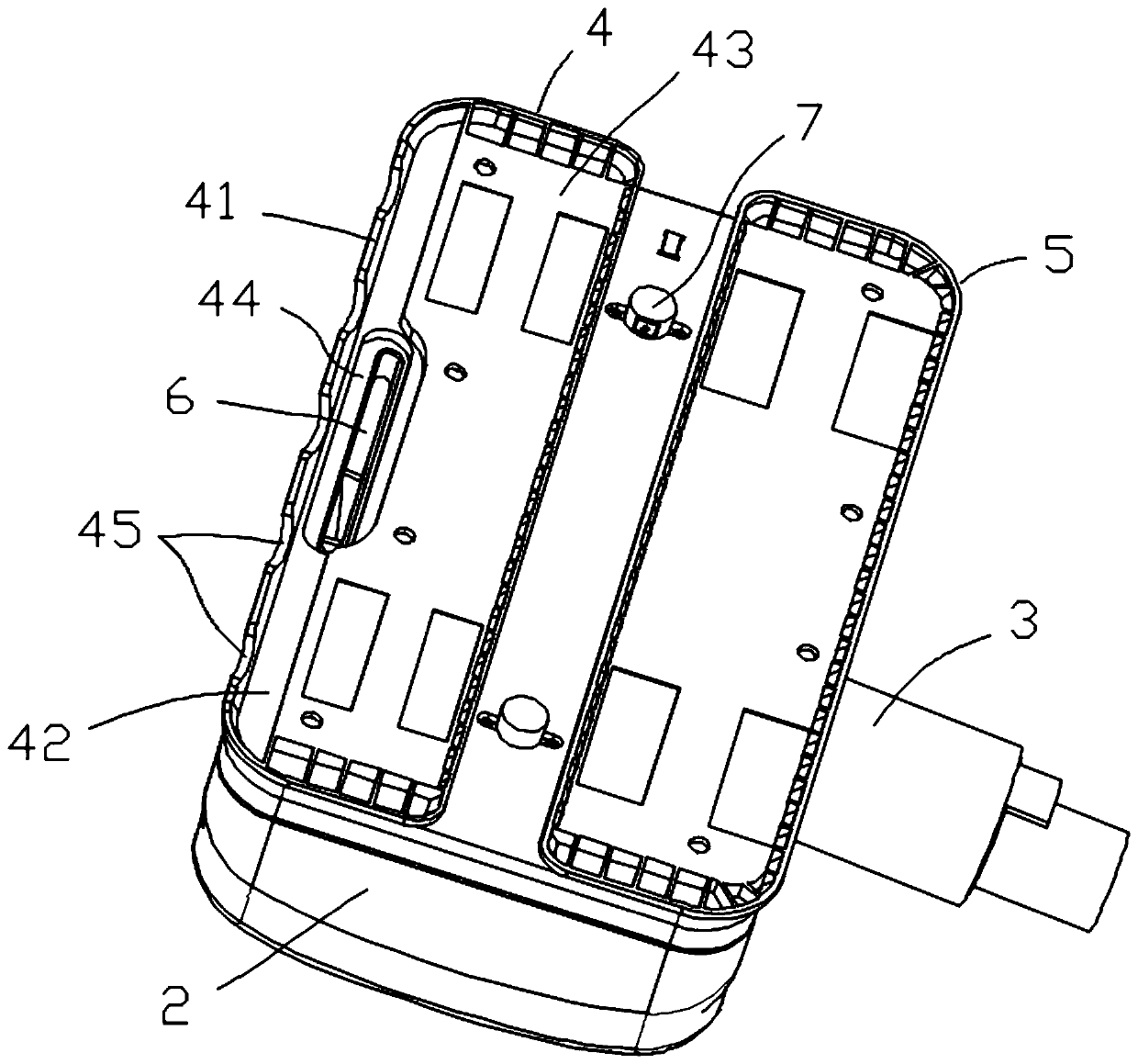

[0068] This embodiment provides a vacuum cleaner brush head 1, which can be used as a vacuum cleaner brush head.

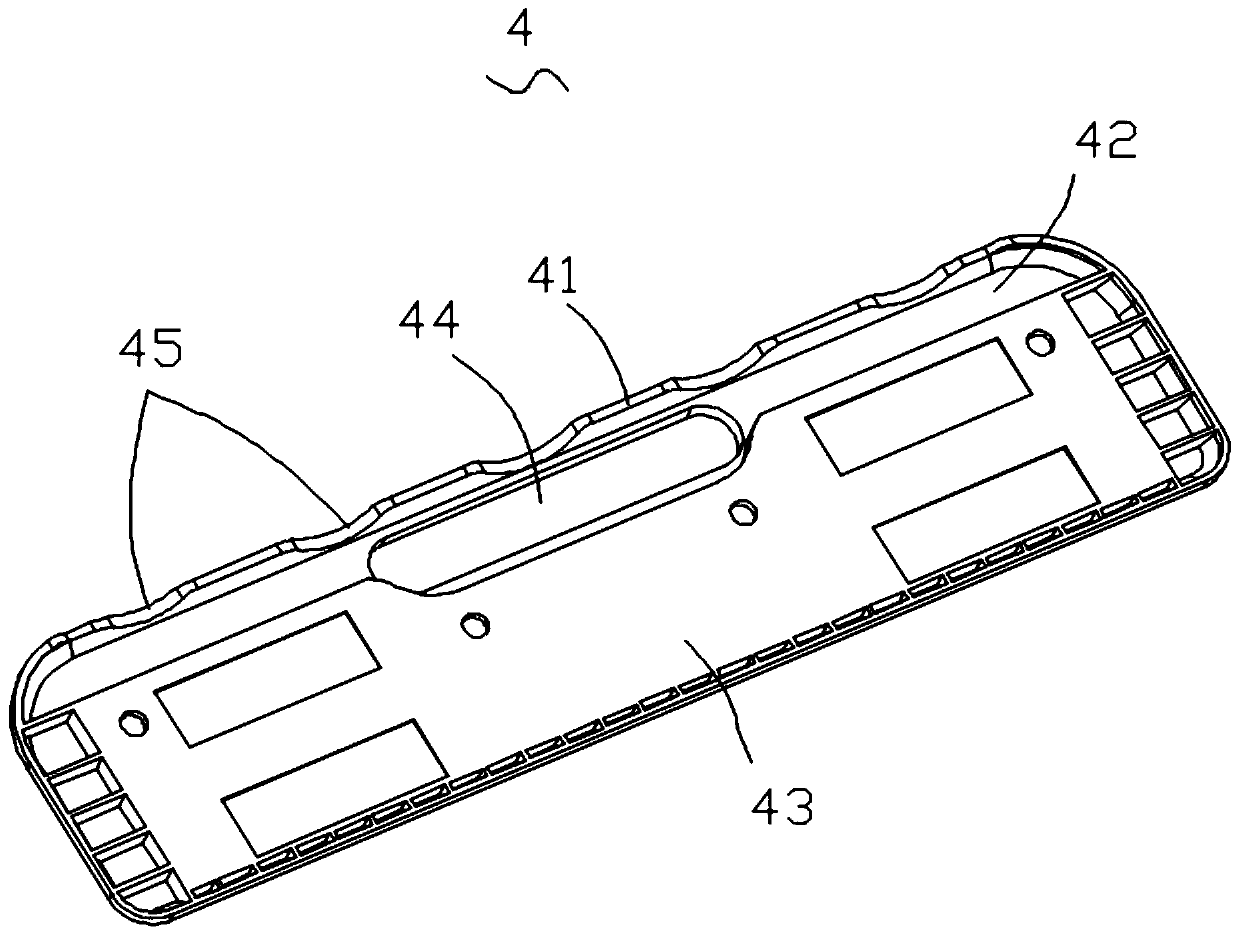

[0069] Such as Figure 1-Figure 3 As shown, the vacuum cleaner brush head 1 includes a brush head body 2, a front wiper plate 4, a rear wiper plate 5, a wiper plate driving device and a water spray assembly. The brush head body 2 is provided with a dust suction pipeline, and the dust suction pipeline is formed with a dust suction port 6 on the front side of the bottom of the brush head body 2, and the front wiper plate 4 and the rear wiper plate 5 are respectively arranged at the bottom of the brush head body 2 , the front wiping board 4 and the rear wiping board 5 are respectively provided with rags, the wiping board driving device is arranged in the brush head body 2, and the water spray port of the water spray assembly is arranged on the bottom of the brush head body 2 and is located at the front wiping board 4 and the front wiping board 4. Between the 5 wiper...

Embodiment 2

[0115] This embodiment provides a vacuum cleaner brush head 1, which can be used as a vacuum cleaner brush head. Compared with embodiment 1, the main difference of this embodiment is:

[0116] Such as Figure 16 As shown, the rear wall 46 of the dust collection tank has a plurality of toothed cutters, and the blades of the toothed cutters face the dust collection tank 42 . Among them, the shape of the tooth cutter includes various shapes such as triangular teeth, trapezoidal teeth, and comb teeth.

[0117] Thus, when encountering hair and other garbage, the tooth knife can first scoop up the garbage and suck it away through the suction port 6, which can improve the effect of hair suction, eliminate or reduce the hair before it has time to be sucked and sucked. Dust mouth 6 and the situation that the hair has been involved under the rag further improves the cleaning effect.

[0118] Preferably, as Figure 17 As shown, the transition portion between the rag mounting portion ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap