Multi-curved-surface steel plate fitting, extruding, filing and deburring device

A technology of extrusion grinding and multi-curved surfaces, which is applied in the direction of feeding devices, other manufacturing equipment/tools, metal processing machinery parts, etc., can solve the problems of steel plate edge cracking, complicated and cumbersome, hands cut or stab wounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

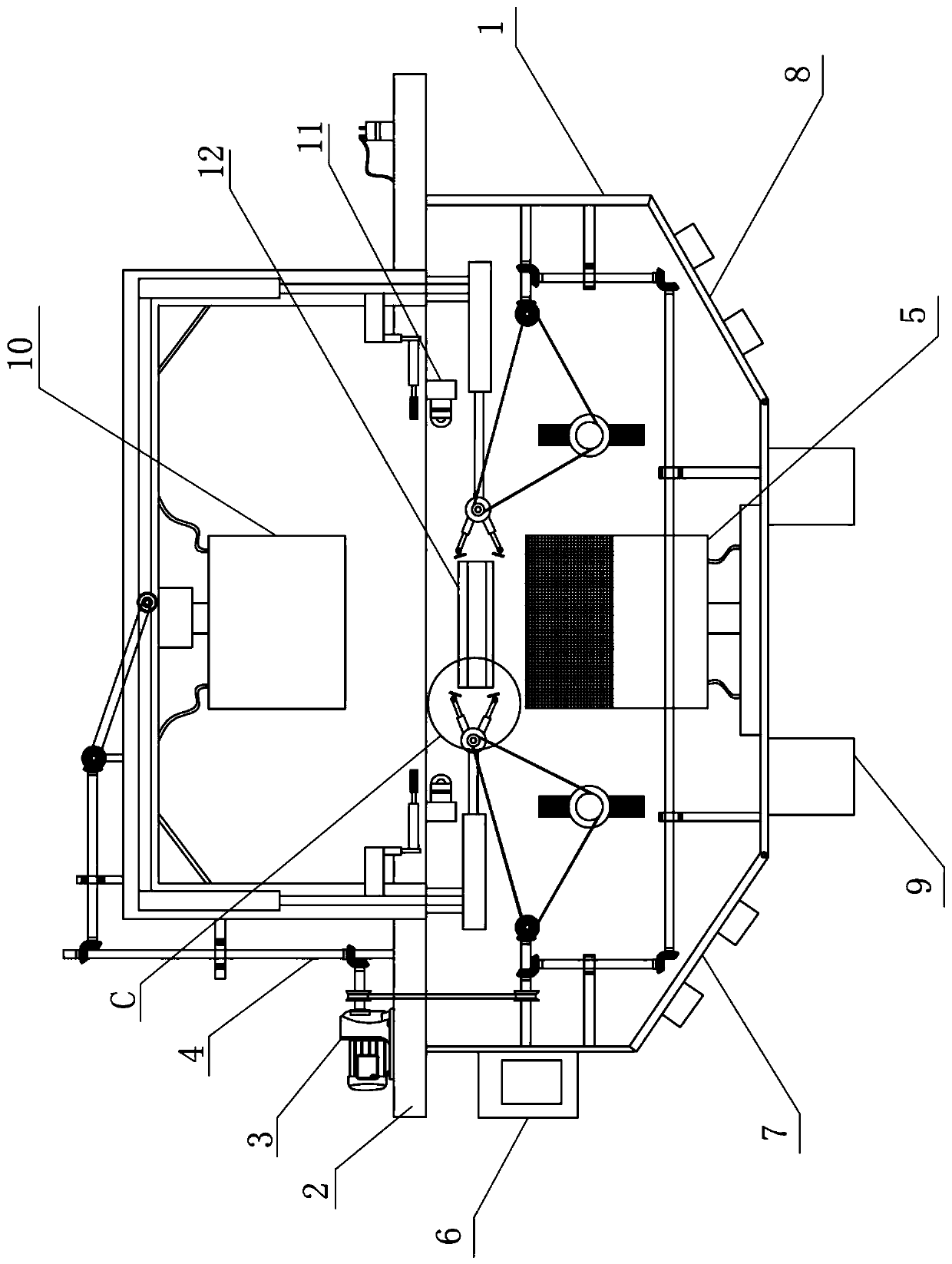

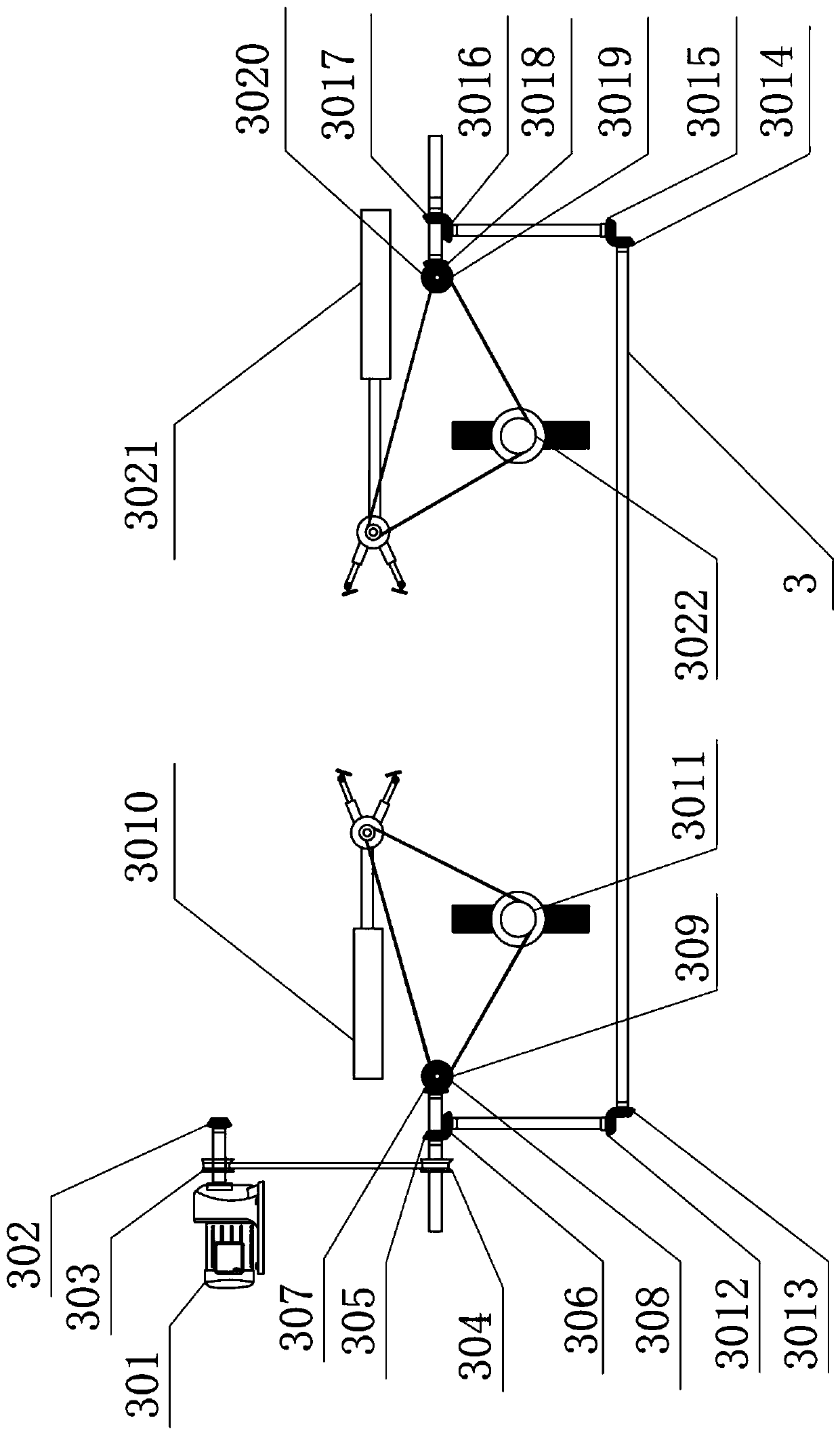

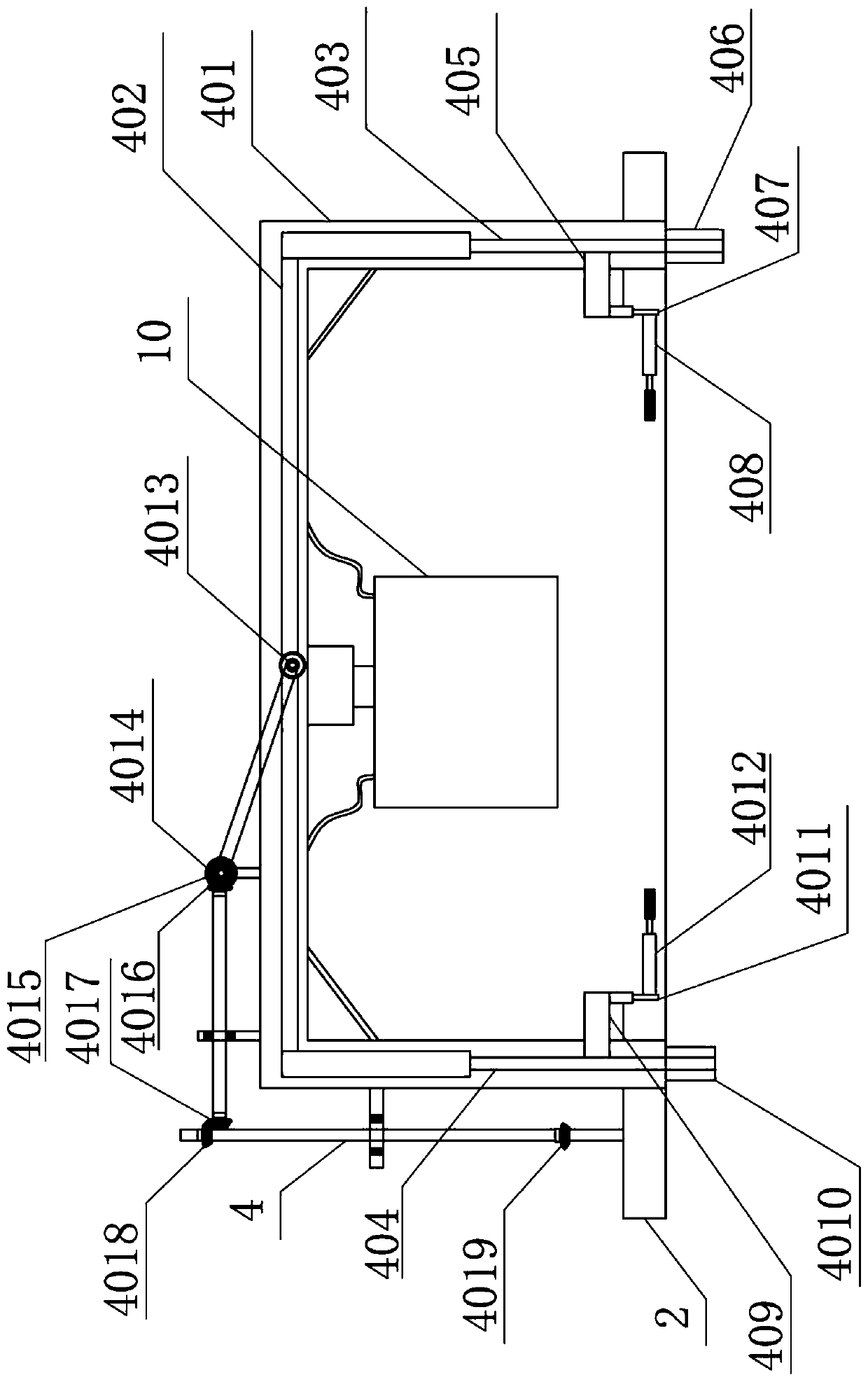

[0025] A multi-curved steel plate fits extrusion grinding and deburring device, such as Figure 1-7 As shown, it includes a support frame 1, a workbench 2, a bilateral transmission grinding mechanism 3, a mobile double-sided grinding mechanism 4, a first extrusion module 5, a control display screen 6, a first cleaning valve 7, and a second cleaning valve. Valve 8, foot 9, second extrusion module 10, infrared sensor 11 and curved steel plate 12, the top left and right parts of the support frame 1 are welded with the workbench 2, and the inner middle of the support frame 1 is provided with a double-sided transmission mill file mechanism 3, and the left bottom end of the bilateral drive grinding mechanism 3 is connected to the workbench 2, the middle bottom end of the support frame 1 is welded to the first extrusion module 5, and the upper left side of the support frame 1 is connected to the control The display screen 6 is connected by bolts, the left lower part of the support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com