Printing nozzle

A technology of printing nozzles and screw pumps, applied in biochemical instruments, biochemical equipment and methods, coating devices, etc., can solve the problems of long time consumption, complicated disassembly process, and many disassembly steps, so as to reduce constraints and facilitate disassembly and assembly Efficient, less restrictive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

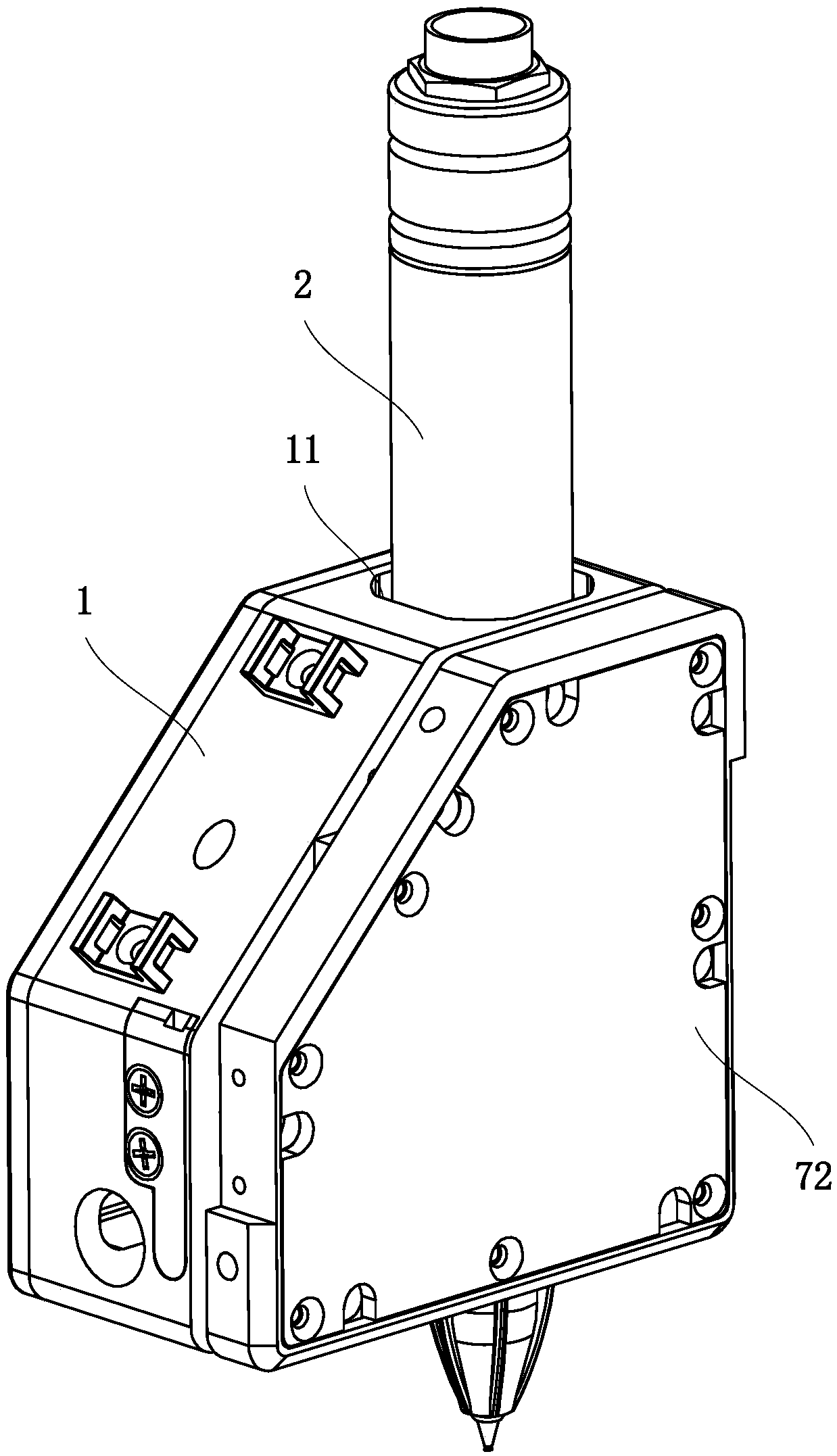

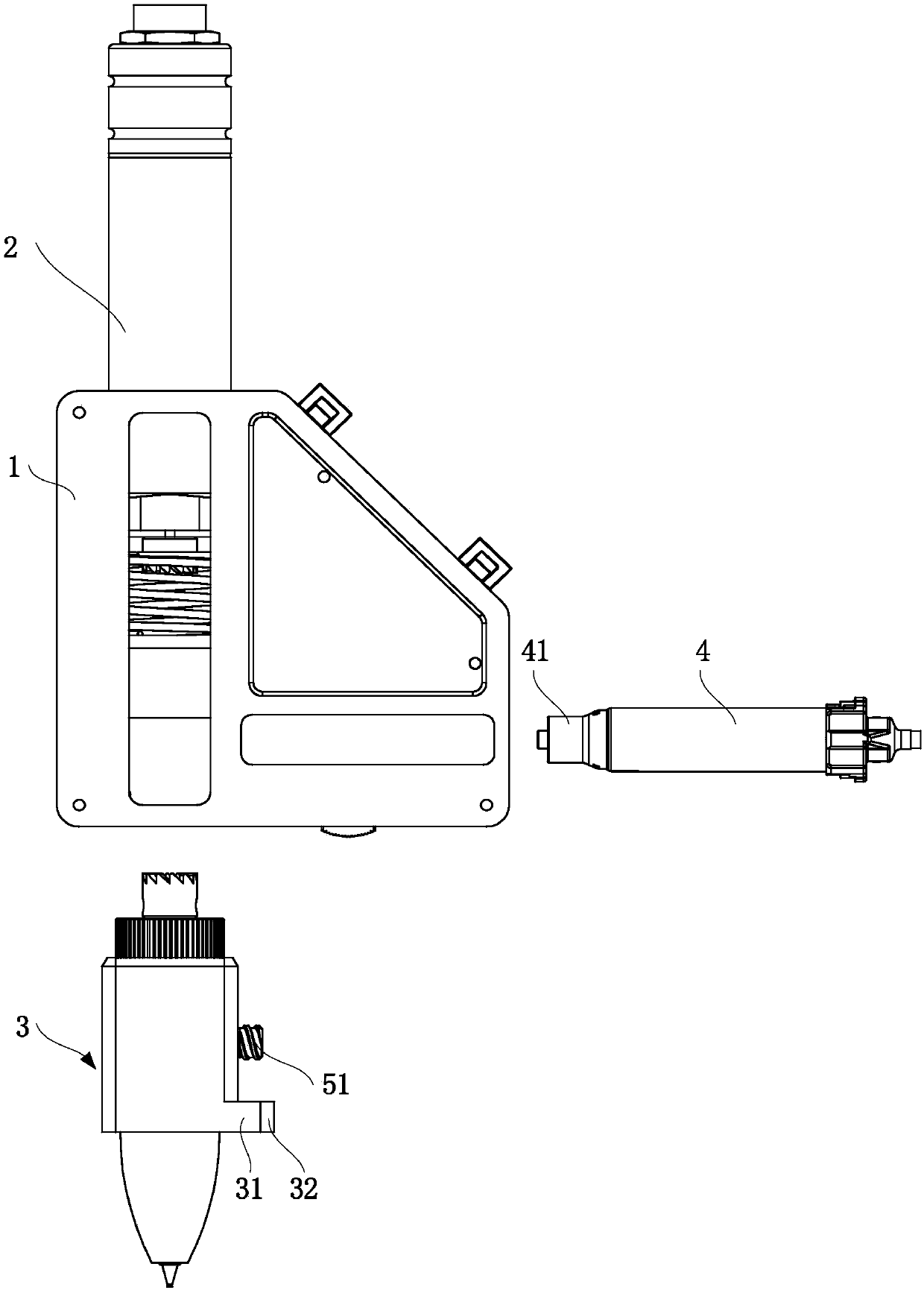

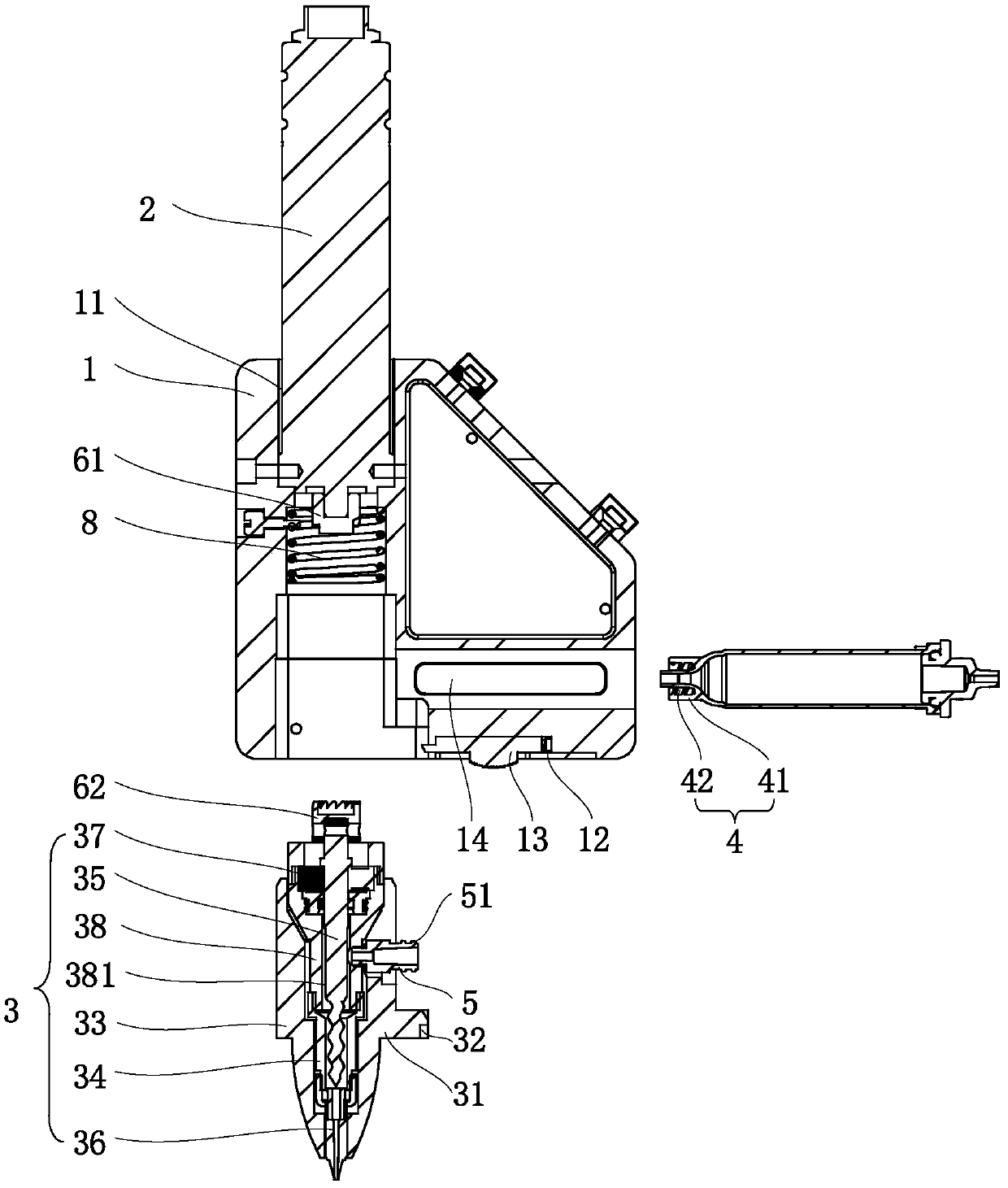

[0047] Combine below Figure 1 to Figure 7 The technical solution provided by the present invention is described in more detail.

[0048] see Figure 1 to Figure 3 , the embodiment of the present invention provides a print nozzle, including a casing 1 , a driving part 2 and a screw pump assembly 3 . The casing 1 includes a mounting hole 11 , the driving component 2 is mounted on one end of the mounting hole 11 , and the screw pump assembly 3 is mounted on the other end of the mounting hole 11 . The end of the drive shaft of the drive part 2 and the end of the rotor 35 of the screw pump assembly 3 form a fit that can drive and rotate, but does not form constraints in the disassembly direction, so that the drive part 2 can drive the rotor 35 to rotate without affecting the screw. Disassembly of pump assembly 3.

[0049] In some embodiments, the disassembly direction refers to a direction parallel to the axial direction of the rotor 35 of the screw pump assembly 3 and away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com