A Mechanized Unlocking Device for Polyurethane Foam Plastic Mold

A technology of foam plastics and unlocking devices, which is applied in the field of mechanized manufacturing, can solve the problems of increased production efficiency, high operating intensity, and low production efficiency of closed-mold foaming products, so as to reduce manual operating intensity, improve efficiency, and improve disassembly and assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The invention provides a mechanized mold unlocking device for polyurethane foam plastics. The mold is designed as an inner mandrel mold and an outer mold for pulling, and is equipped with a turning mechanism and a numerically controlled hydraulic clamping and pulling device to realize the mechanized disassembly and assembly of the mold.

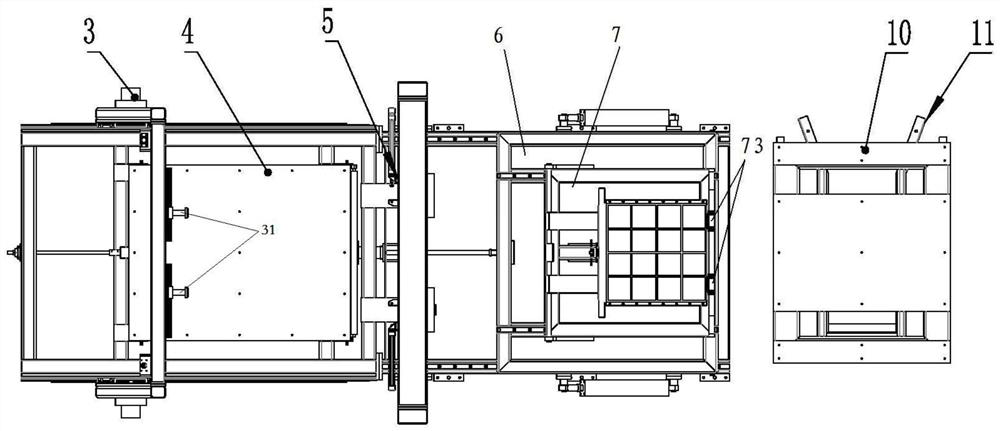

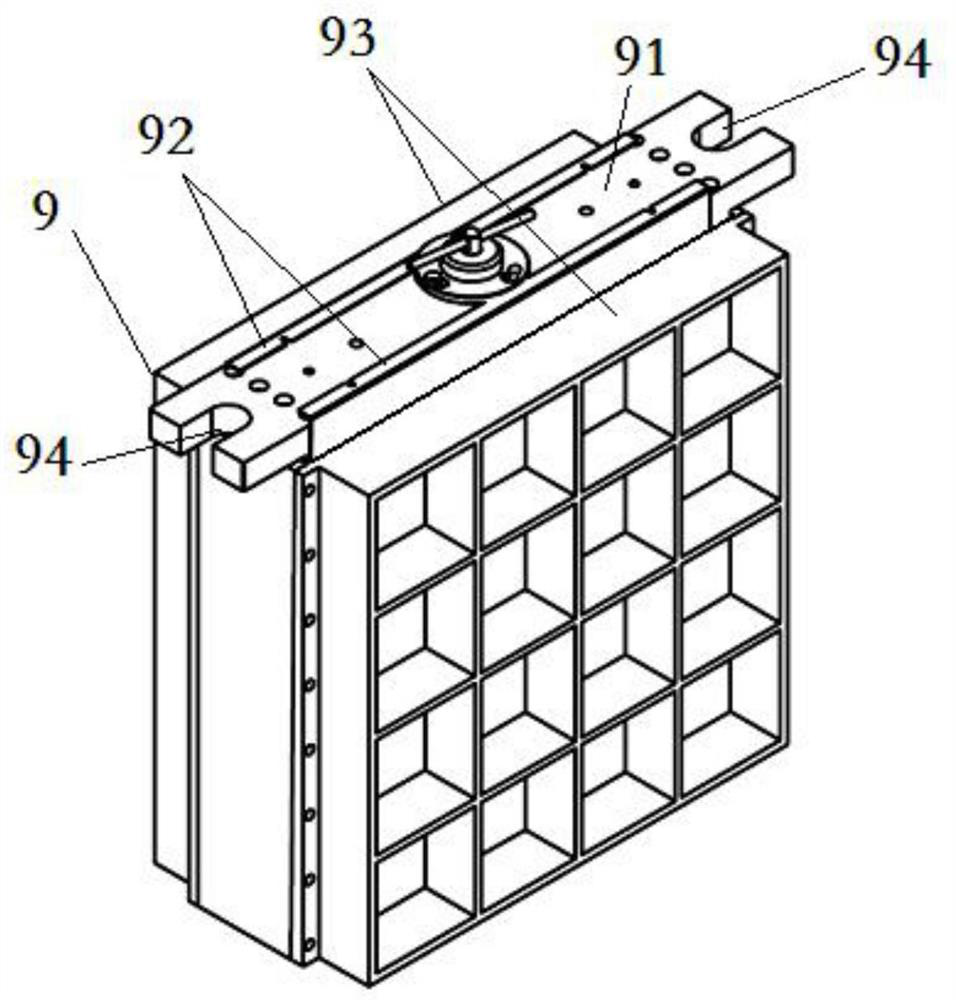

[0029] Such as figure 1 , figure 2 As shown, the polyurethane foam plastic mold unlocking device in the present invention comprises a kind of mechanized polyurethane foam plastic mold unlocking device, comprises base 1, mold pushing mechanism 3, mold platform 4, mold pull-off mechanism 5, hydraulic movement mechanism 6, mold overturning Mechanism 7, pull-type foaming mold 9, mold running car 10 and positioning mechanism 11; wherein, the base 1 is a table-like structure placed horizontally; the mold pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap