A kind of technological method of utilizing ethoxylated bisphenol a diacrylate waste water to prepare thickener

A technology of ethoxylated bisphenols and diacrylates, which is applied in the field of chemical waste liquid treatment, can solve technical problems that cannot be effectively overcome, high water inlet conditions, high treatment costs, etc., and achieve reliable performance and preparation Simple method and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below with reference to specific embodiments of the present invention is further described in detail:

[0024] The present invention provides an embodiment of an ethoxylated bisphenol A diacrylate process for the preparation of an ester thickeners wastewater use, comprising the steps of:

[0025] The acrylic acid-containing wastewater into the reactor and the styrene, diallyl phthalate and acrylamide obtained mixture, a radical polymerization initiator;

[0026] Replaced with nitrogen gas phase portion inside the reactor, the mixture is heated to 75 ℃ -85 ℃;

[0027] The reactor was repeatedly into the timing of an aqueous solution of sodium persulfate was added, and the mixture was maintained at control 75 ℃ -85 ℃;

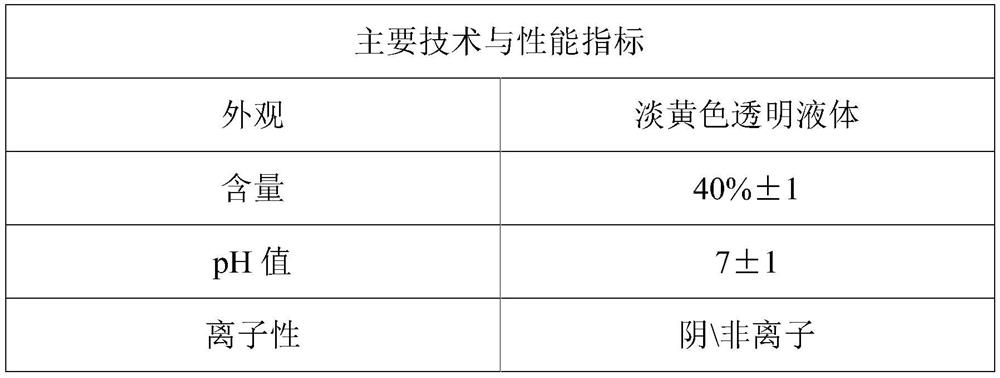

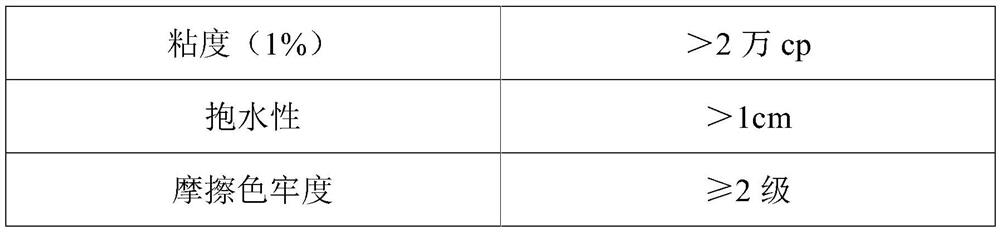

[0028] After the end of the radical copolymerization of a mixture, the mixture was cooled and sodium hydroxide solution and water, adjust the pH and concentration of the reaction solution to give a thickener. Get the main technical and performance indicators a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com