Preparation method and application of late-stage strength-enhancing cementitious material for red mud-based cement concrete

A cement concrete and post-strength technology, which is applied in the field of cement concrete, can solve problems such as the limitation of the amount of red mud, and achieve the effects of avoiding efflorescence, increasing post-strength, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0031] A preparation method of a late-stage strength-enhancing cementitious material for red mud-based cement concrete, comprising the following steps:

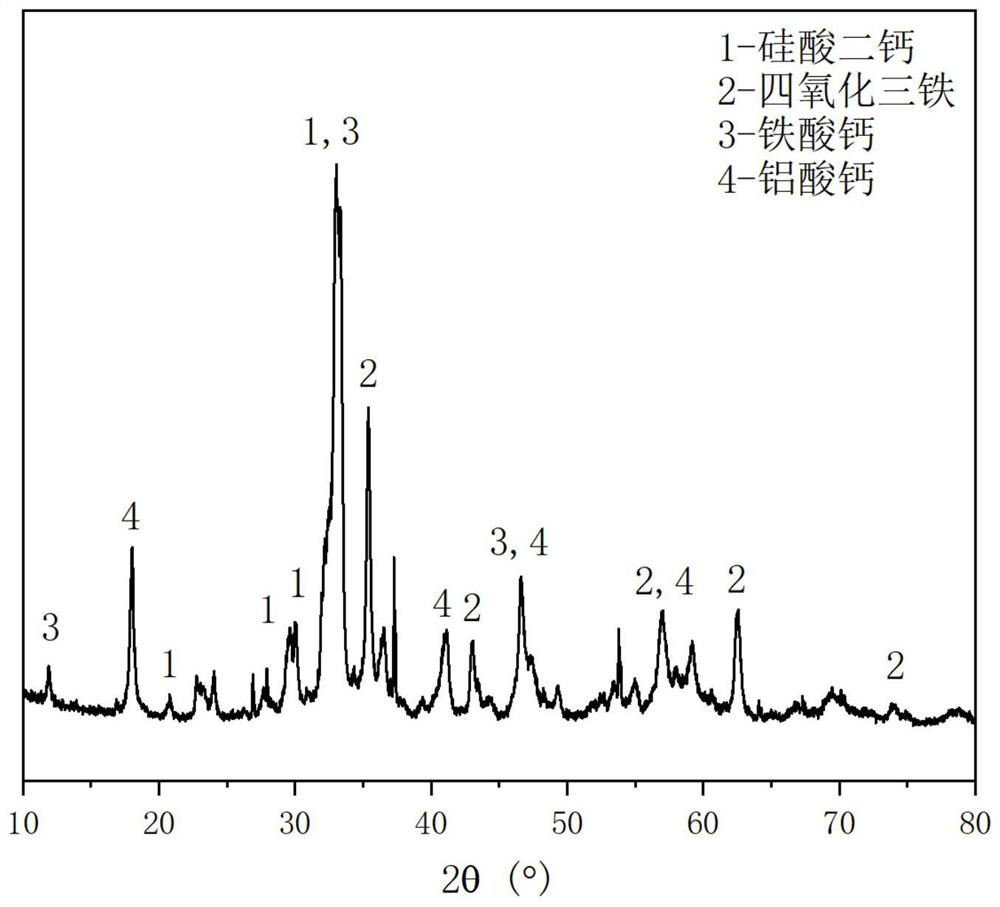

[0032] (1) Dry the red mud to a water content of less than 1%, and grind it to a 0.2mm sieve with a remainder of 1%. In parts by weight, 40 parts of the red mud, 30 parts of sodium hydroxide, and 30 parts of calcium oxide were mixed uniformly, and the obtained mixture was added with water to prepare a slurry (solid-to-liquid ratio of 1:10). Then, the slurry was put into a closed high-pressure container, and the temperature was raised to 200° C. and then kept for 120 min. After the insulation is completed, it is naturally cooled, the supernatant is discarded, and the solid is washed with clean water for several times until pH2 O mass fraction is 1.32%, K 2 The mass fraction of O was 0.27%, and the ratio of aluminum to silicon was 0.73. The main components of the modified red mud were garnet and hematite.

[0033] (2) adding ...

no. 2 example

[0040] A preparation method of a late-stage strength-enhancing cementitious material for red mud-based cement concrete, comprising the following steps:

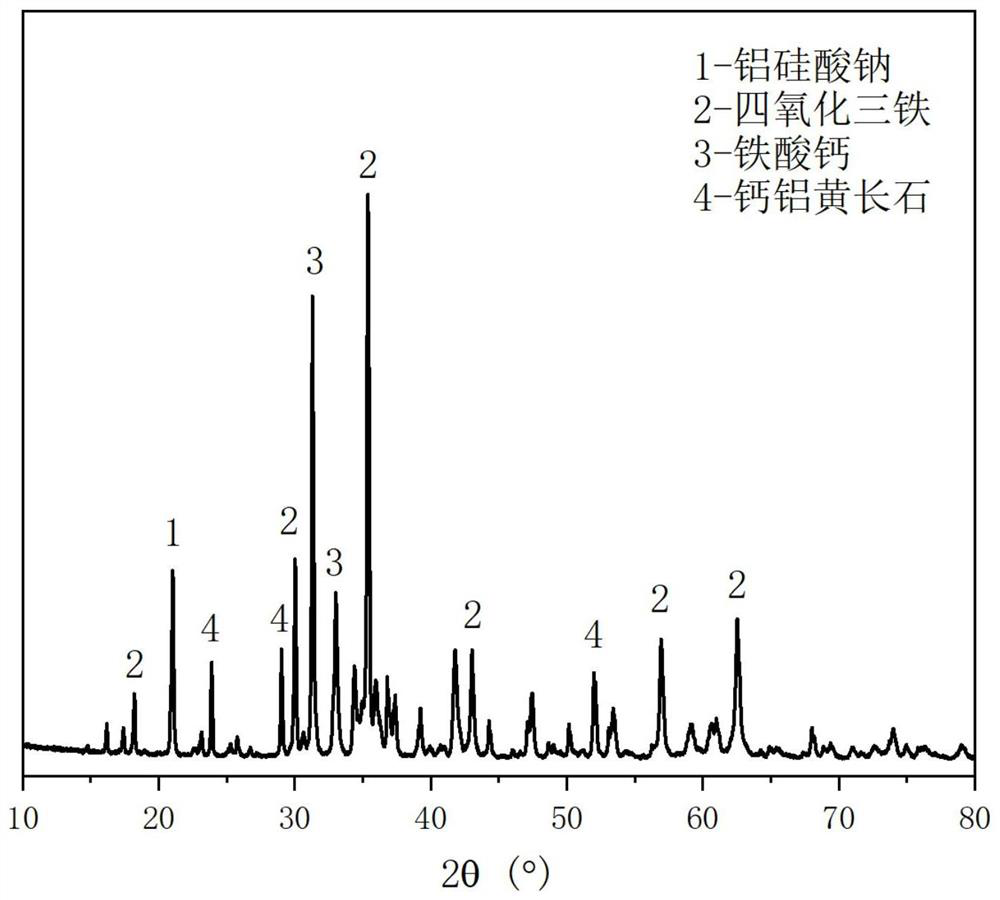

[0041] (1) Dry the red mud to a water content of less than 1%, and grind it to a 0.2mm sieve with a remainder of 1%. In parts by weight, 42 parts of the red mud, 25 parts of sodium hydroxide, and 33 parts of calcium oxide were mixed uniformly, and the obtained mixture was added with water to prepare a slurry (solid-to-liquid ratio of 1:10). Sodium hydroxide is used to provide the OH required for the reaction - Concentration and calcium oxide are used to synthesize calcium-iron-aluminum garnet. Then, the slurry was put into a closed high-pressure container, and the temperature was raised to 210° C. and then kept for 120 min. After the insulation is completed, it is naturally cooled, the supernatant is discarded, and the solid is washed with clean water for several times until pH2 O mass fraction is 1.48%, K 2 The mass fract...

no. 3 example

[0049] A preparation method of a late-stage strength-enhancing cementitious material for red mud-based cement concrete, comprising the following steps:

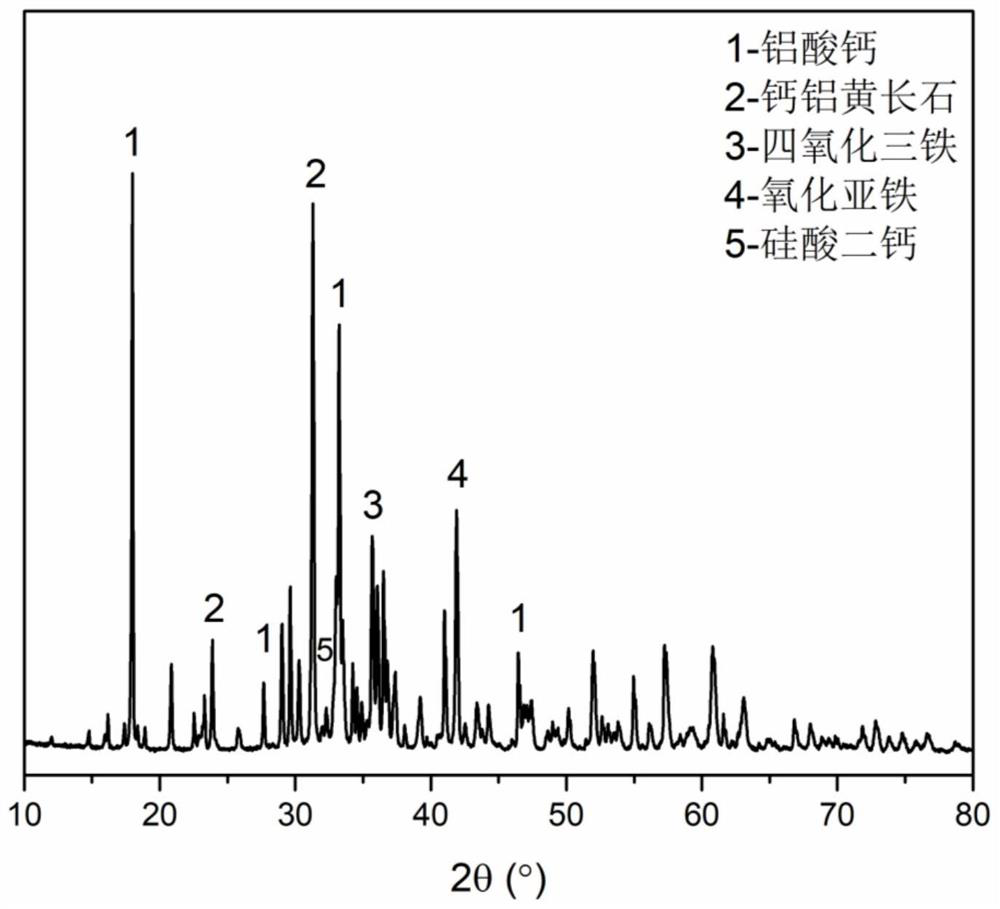

[0050] (1) Dry the red mud to a water content of less than 1%, and grind it to a 0.2mm sieve with a remainder of 1%. In parts by weight, 37 parts of the red mud, 35 parts of sodium hydroxide, and 28 parts of calcium oxide were mixed uniformly, and the obtained mixture was added with water to prepare a slurry (solid-to-liquid ratio of 1:10). Sodium hydroxide is used to provide the OH required for the reaction - Concentration and calcium oxide are used to synthesize calcium-iron-aluminum garnet. Then, the slurry was put into a closed high-pressure container, and the temperature was raised to 220° C. and then kept for 120 min. After the insulation is completed, it is naturally cooled, the supernatant is discarded, and the solid is washed with clean water for several times until pH2 O mass fraction is 0.79%, K 2 The mass fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com