A kind of preparation method of high transmittance sulfone polymer and prepared sulfone polymer

A high light transmittance, polymer technology, applied in the field of sulfone polymers, can solve the problems of poor heat resistance, decreased light transmittance, gel-like precipitation, etc., to improve light transmittance, eliminate application restrictions, and reduce product haze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

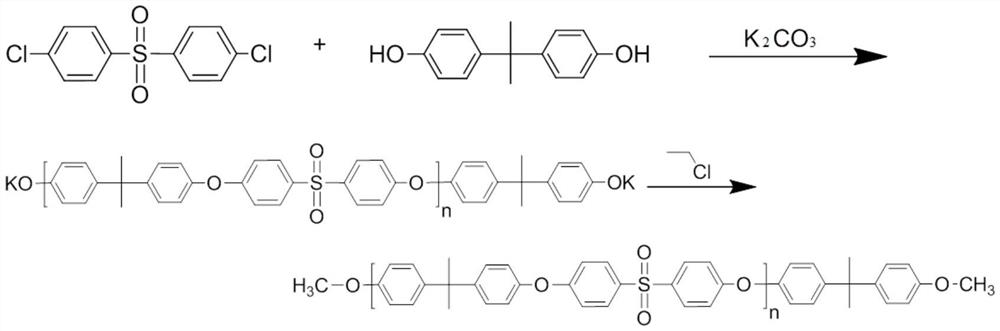

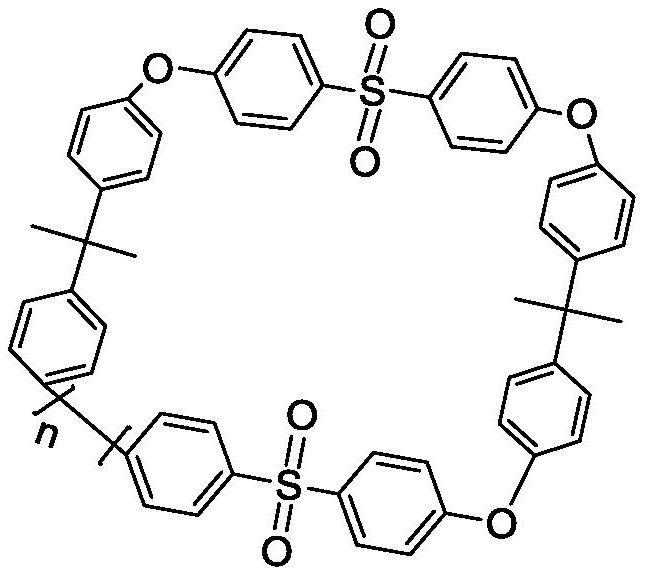

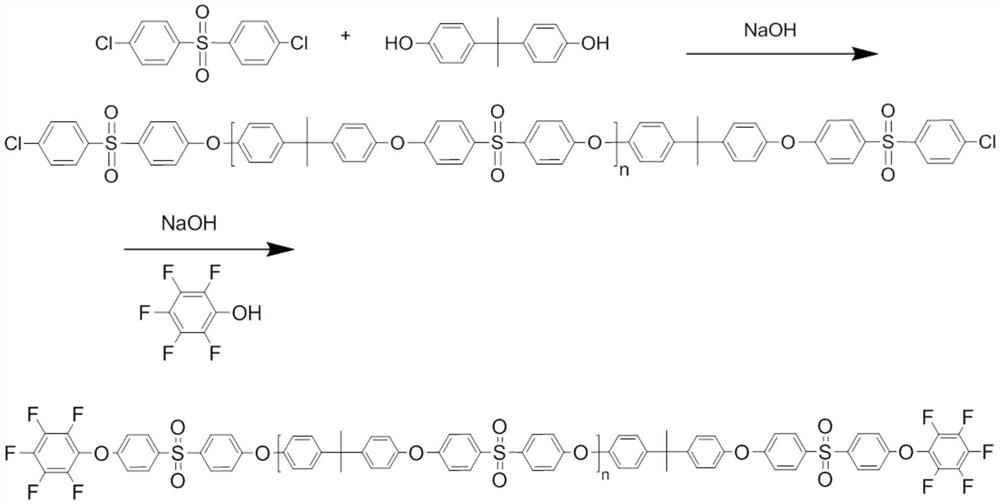

Method used

Image

Examples

Embodiment 1

[0029] Connect the water separator, straight condenser tube, thermometer, stirrer and other devices to the 1000ml four-necked flask. After the device was replaced with nitrogen, 367g of o-xylene was added, stirring was started, 65.843g of potassium carbonate and 90.653g of bisphenol A were added, and the nitrogen atmosphere was continued to be maintained; the temperature was heated to 144°C and refluxed, and the water generated during the reaction was removed from the mixture. Drain the system from the water tank. When no more water was discharged, the water was let off, the solvent was evaporated from the reaction system to dryness, and the temperature of the system was raised to 180°C.

[0030] Accurately weigh 114.8g of 4,4'-dichlorodiphenylsulfone, dissolve it in 402g of sulfolane saturated with nitrogen, and heat it up to 180°C to prepare a solution. The solution was added to the reaction system under nitrogen protection, kept at 180 ° C and reacted at -0.09MPa for 6 hou...

Embodiment 2

[0034] Connect the water separator, straight condenser tube, thermometer, stirrer and other devices to the 1000ml four-necked flask. After the device was replaced with nitrogen, 491g of n-nonane was added, stirring was started, 32.472g of sodium hydroxide and 90.288g of bisphenol A were added, and a nitrogen atmosphere was continued; the temperature was heated to 126°C and refluxed, and the water generated during the reaction was changed from Drain the system from the water separator. When no more water was discharged, the water was let off, the solvent was evaporated out of the reaction system to dryness, and the temperature of the system was raised to 185°C.

[0035] Accurately weigh 114.8g of 4,4'-dichlorodiphenylsulfone, dissolve it in 344g of sulfolane saturated with nitrogen, and heat it to 185°C to prepare a solution. The solution was added to the reaction system under nitrogen protection, kept at 185°C and reacted at -0.09MPa for 8 hours, the viscosity of the system r...

Embodiment 3

[0039] Connect the water separator, straight condenser tube, thermometer, stirrer and other devices to the 1000ml four-necked flask. After the device was replaced by helium, 523g of xylene was added, stirring was started, 43.68g of potassium hydroxide and 72.54g of 4,4'-dihydroxybiphenyl were added, and the helium atmosphere was continued; The water produced in the reaction process was discharged from the water separator. When no more water was discharged, the water was let off, the solvent was evaporated out of the reaction system to dryness, and the temperature of the system was raised to 170°C.

[0040] Accurately weigh 114.8g of 4,4'-dichlorodiphenylsulfone, dissolve it in 689g of sulfolane saturated with helium gas, and heat it to 170°C to prepare a solution. The solution was added to the reaction system under the protection of helium, kept at 170°C and reacted at -0.08MPa for 3 hours, the viscosity of the system reached 500cp, 310g of sulfolane was added to the system f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com