Button type guide rail box structure

A guide rail box and button technology, applied in lighting devices, lighting device parts, lighting auxiliary devices, etc., can solve the problems of inoperability, complicated operation, large space, etc., to reduce the installation space, the appearance is flat and beautiful, and the space is occupied. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

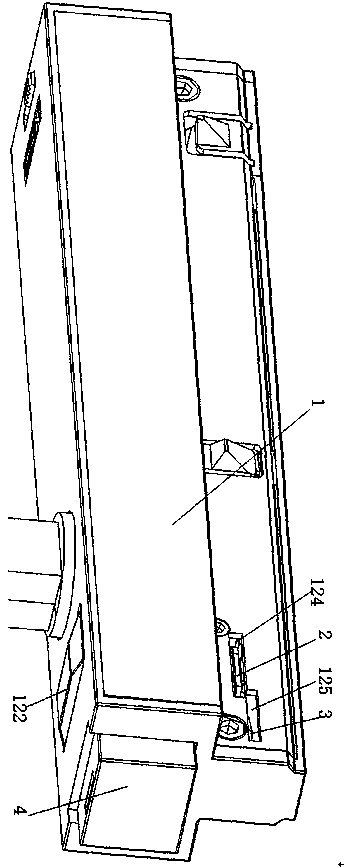

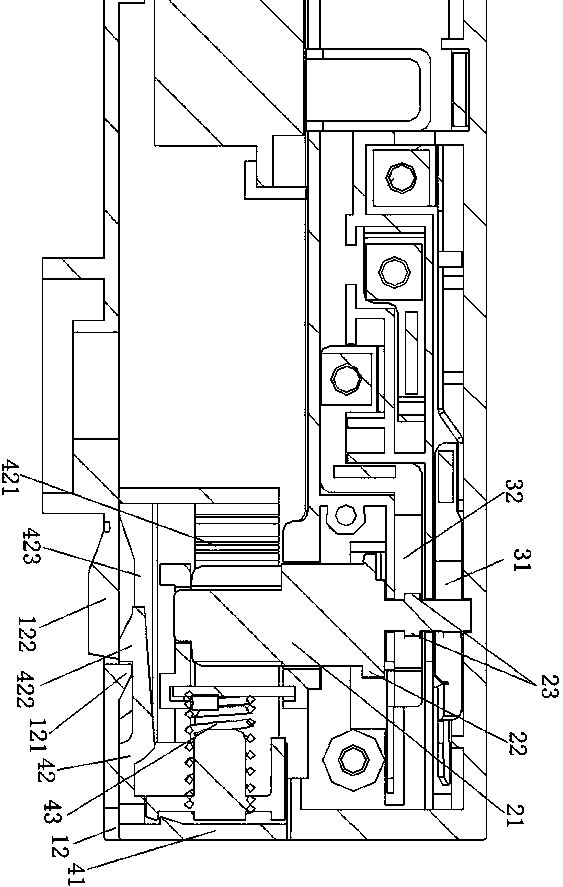

[0029] A push-button rail box structure, such as Figure 1-7 As shown, it includes: rail box 1, gear assembly 2, electric spring 3 and button assembly 4, rail box 1 includes matching first side wall 11 and second side wall 12, first side wall 11 and second side wall The wall 12 is screwed and fixed by screws 13; the gear assembly 2 is installed in the guide rail box 1, and in the process of its rotation, it expands and contracts horizontally from the side wall of the guide rail box 1 to install the guide rail box 1 on the guide rail. 1 is provided with an arc-shaped limiting groove 126 for limiting the gear assembly 2; the electric shrapnel 3 is installed in the guide rail box 1, and is horizontally stretched outward from the side wall of the guide rail box 1 during the rotation of the gear assembly 2 To be in contact with the guide rail bar installed in the guide rail; the button assembly 4, installed at one end of the guide rail box 1, is movably connected with the guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com