Ultralight breathable environmental-friendly bedding and preparation process thereof

A preparation process, technology of bedding, applied in the field of textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

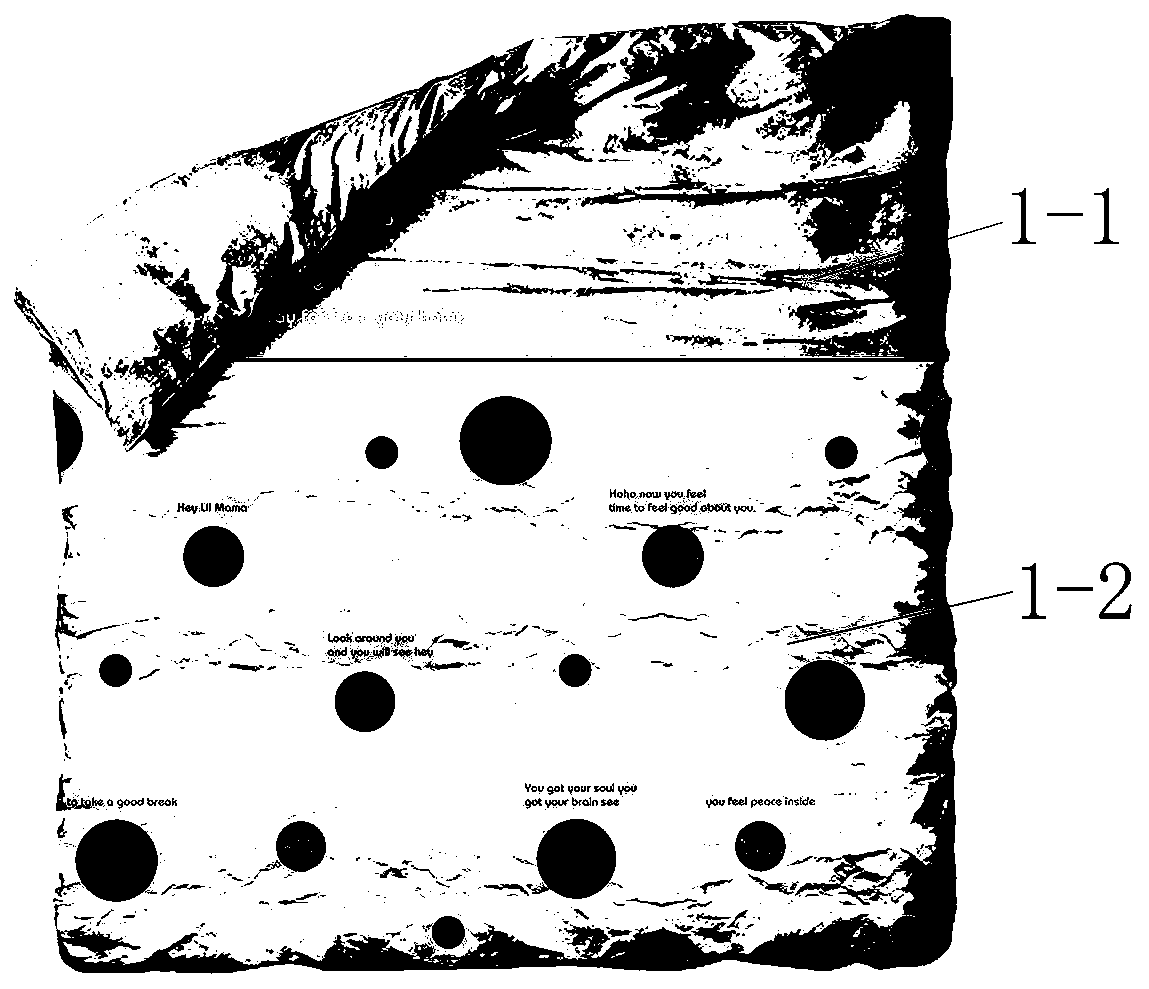

[0064] Such as figure 1 Shown is the first type: a schematic diagram of the structure of the quilt cover made of satin fabric 1-1 and DuPont fabric 1-2 by parallel sewing, and its preparation process is as follows:

[0065] (1-1) Choose 60S satin fabric to make quilt lining;

[0066] (1-2) Choose 60S satin fabric and DuPont fabric to stitch together in parallel to form a quilt cover, of which 1 / 3 of the quilt cover is 60S satin fabric, and 2 / 3 of it is DuPont fabric;

[0067] (1-3) The DuPont fabric in step (1-2) can optionally be printed, embroidered or embossed;

[0068] (1-4) Sew the inside of the quilt in step (1-1) and the edge of the quilt in step (1-2) to make a quilt cover.

Embodiment 2

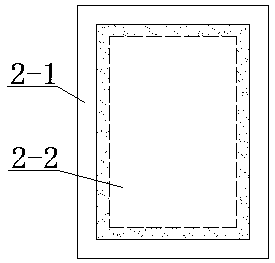

[0070] Such as figure 2 Shown is the second type: the quilt cover is connected by a quilt cover main body 2-1 made of satin fabric and a replaceable quilt cover 2-2 made of DuPont fabric, and the quilt cover includes a quilt cover made of satin fabric The quilt cover main body 2-1 and the replaceable quilt cover 2-2 made of DuPont fabric, the quilt surface is provided with an opening, and a connecting structure is provided at a circle edge of the opening, and the opening passes through the connecting structure Detachably connects to the replaceable quilt covering it.

[0071] The preparation process is:

[0072] (2-1) Choose 60S satin fabric to make quilt lining;

[0073] (2-2) Choose 60S satin fabric to make the main body of the quilt, and the main body of the quilt has openings such as square, rounded square, round, oval, polygonal, pentagram, and special-shaped;

[0074] (2-3) DuPont fabric is made into a replaceable quilt cover with a corresponding structure according ...

Embodiment 3

[0080] Such as Figure 7 Shown is the third type: the DuPont fabric is cut and pasted on the satin fabric to form a vertical carving pattern. The vertical carving pattern is a single-layer pattern, a multi-layer dislocation progressive positive engraving pattern ( Figure 7 a and Figure 7 b) or multi-layer hollow progressive intaglio pattern ( Figure 7 c).

[0081] The preparation steps are:

[0082] (3-1) Choose 60S satin fabric to make quilt lining;

[0083] (3-2) Choose 60S satin fabric to make the quilt cover;

[0084] (3-3) DuPont fabrics are cut into patterns manually or by laser;

[0085] (3-4) The pattern in step (3-3) is combined on the quilt surface of step (3-2) by single-layer, multi-layer dislocation progressive positive engraving or multi-layer hollow progressive intaglio;

[0086] (3-5) The quilt in step (2-1) is sewn together with the edge of the quilt in step (3-4) to make a quilt cover.

[0087] The breathable and environment-friendly bedding also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com