A carbonless copy paper

A carbonless copy paper and carbon paper technology, applied in the field of carbon paper, can solve the problems of high brittleness of carbonless copy paper, easy torn carbonless copy paper into irregular shapes, affecting people's use, etc., so as to improve the use effect, save manpower and material resources, improve the The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

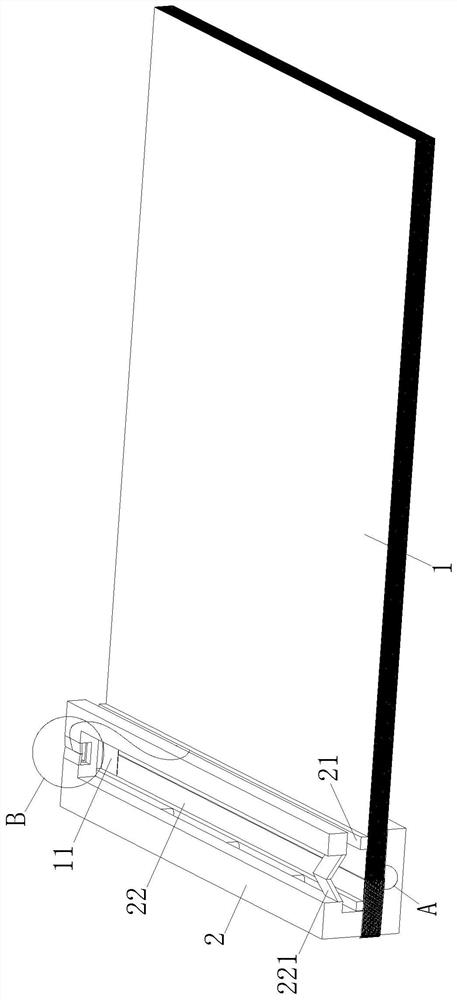

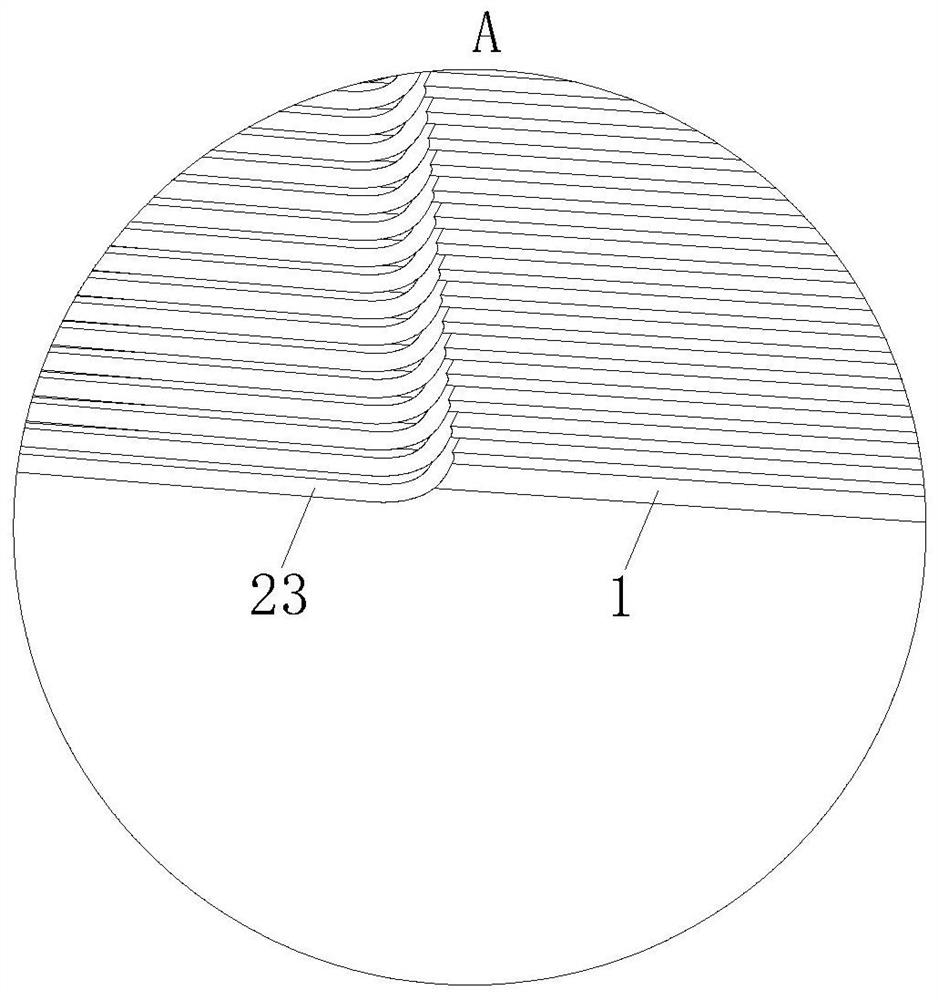

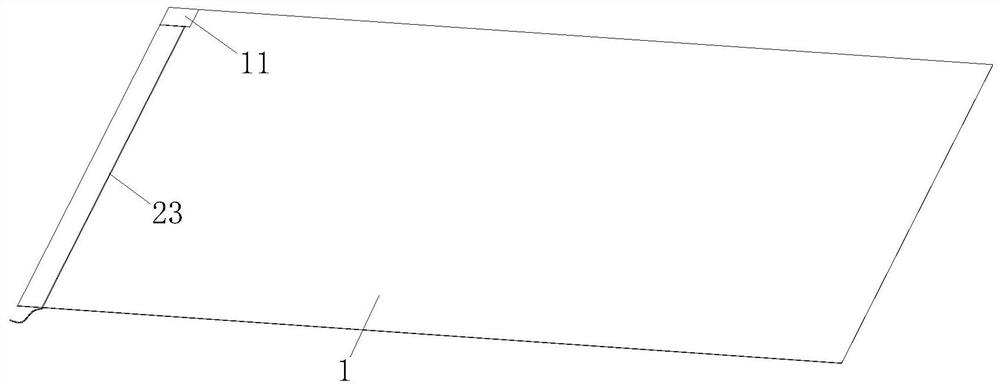

[0023] As an embodiment of the present invention, the U-shaped tearing clip 2 has a U-shaped groove 24 near the end of the notch 22; the U-shaped groove 24 is symmetrically provided with a No. 2 shrapnel 241, so that the tear rope 23 When being pulled up, it can pass through the No. 2 shrapnel 241 and then snap into the U-shaped groove 24, thereby realizing the collection of the tearing rope 23, avoiding the use of the paper body 1 after the number of the tearing rope 23 is too large; when working, when people need When taking the carbon paper, pull up the end of the tearing rope 23 protruding from the paper body 1, so that the tearing rope 23 passes through the No. 1 shrapnel 221, so that the tearing rope 23 produces a tearing force on the paper body 1. When the paper body 1 is torn During the pulling force of the rope 23, the paper body 1 will be torn along the position in contact with the tear rope 23, so that the torn side wall of the paper body 1 is linear, so that the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com