Large square concrete filled steel tube member with multiple cavities

A square steel pipe and concrete technology, applied in building components, structural elements, building types, etc., can solve problems such as the inability to guarantee the transfer of shear force between steel pipes and concrete, the problem of hydration heat that cannot be ignored, and the weakening of interface bonding performance, achieving easy factory-building. Prefabrication and on-site construction, improving bonding performance, reducing the effect of heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

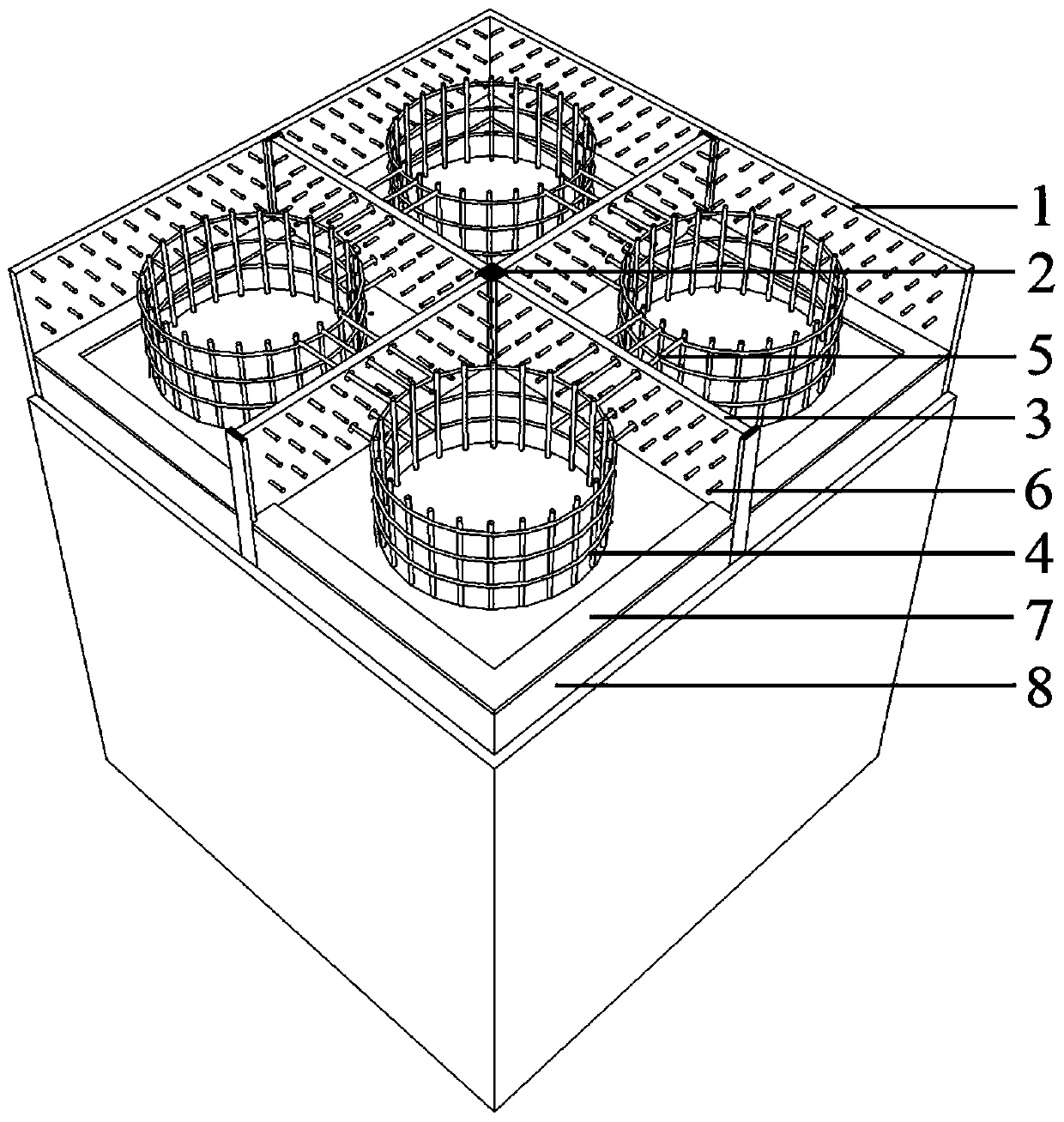

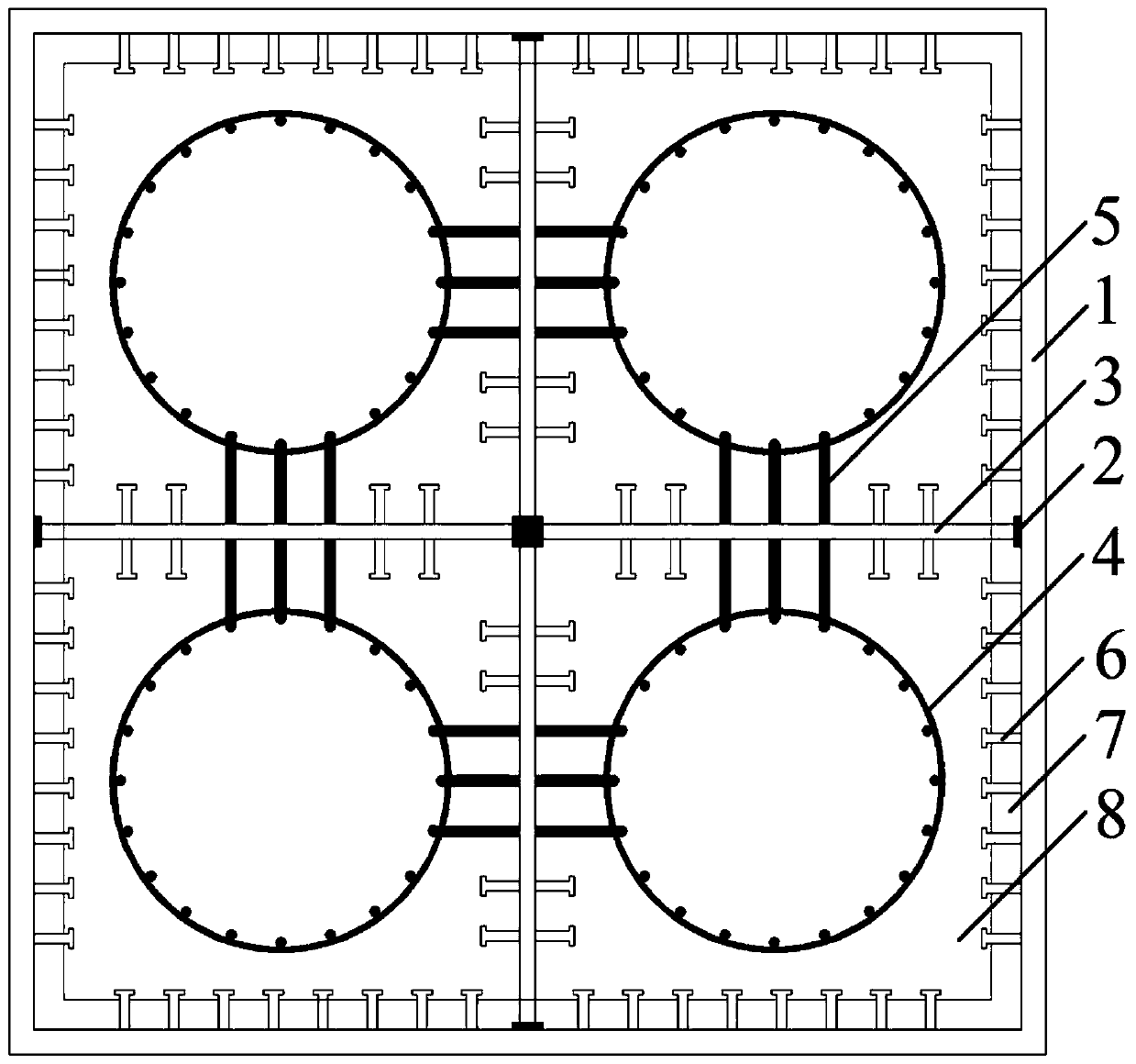

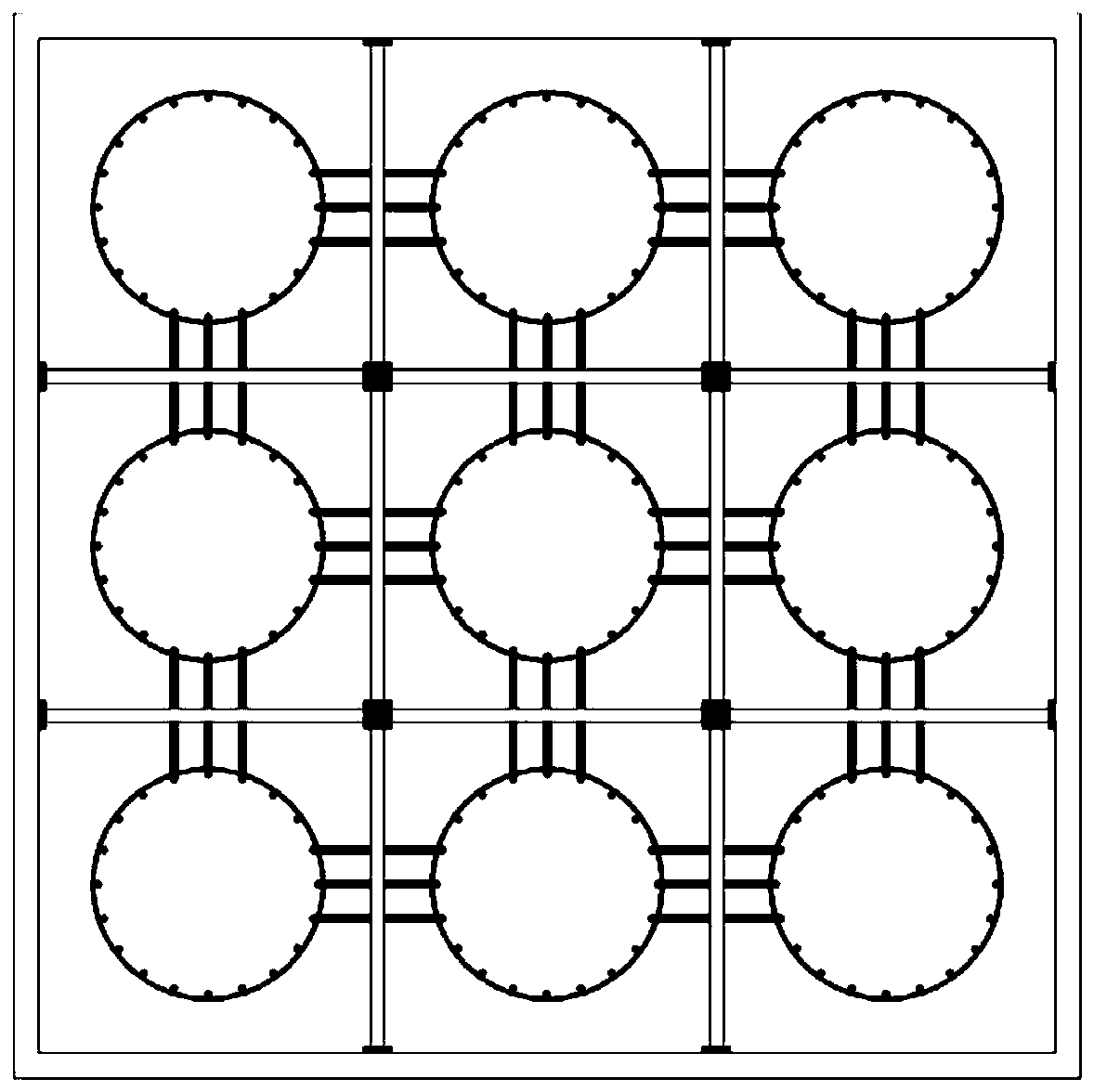

[0037] Such as Figure 1~3 As shown, a multi-cavity giant square steel pipe concrete member, including 1-square steel pipe; 2-connecting steel strips, 3-cavity steel plates; 4-reinforcement cage; 5-tie reinforcement; - hoop ribs; 8 - concrete.

[0038] A multi-cavity giant square steel tube concrete member is characterized in that it includes square steel tubes 1, connecting steel strips 2, cavity steel plates 3, steel cages 4, tie bars 5, studs 6, circumferential ribs 7 and Concrete 8; the sub-cavity steel plate 3 divides the inside of the square steel pipe into multiple cavities, a connecting steel strip 2 is provided at the junction of the sub-chamber steel plate 3, and a connecting steel strip 2 is provided at the junction of the sub-cavity steel plate 3 and the square steel pipe 1, The connecting slats 2 are welded together wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap