Atomizer air inflow pipeline adjusting assembly for atomized metal powder production

A technology for adjusting components and metal powder, which is applied in the direction of additive processing, etc., can solve the problems of high frequency of shutdown and startup, increased loss, complicated process, etc., and achieve the effect of reducing the probability of equipment failure and reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in detail below in conjunction with the accompanying drawings.

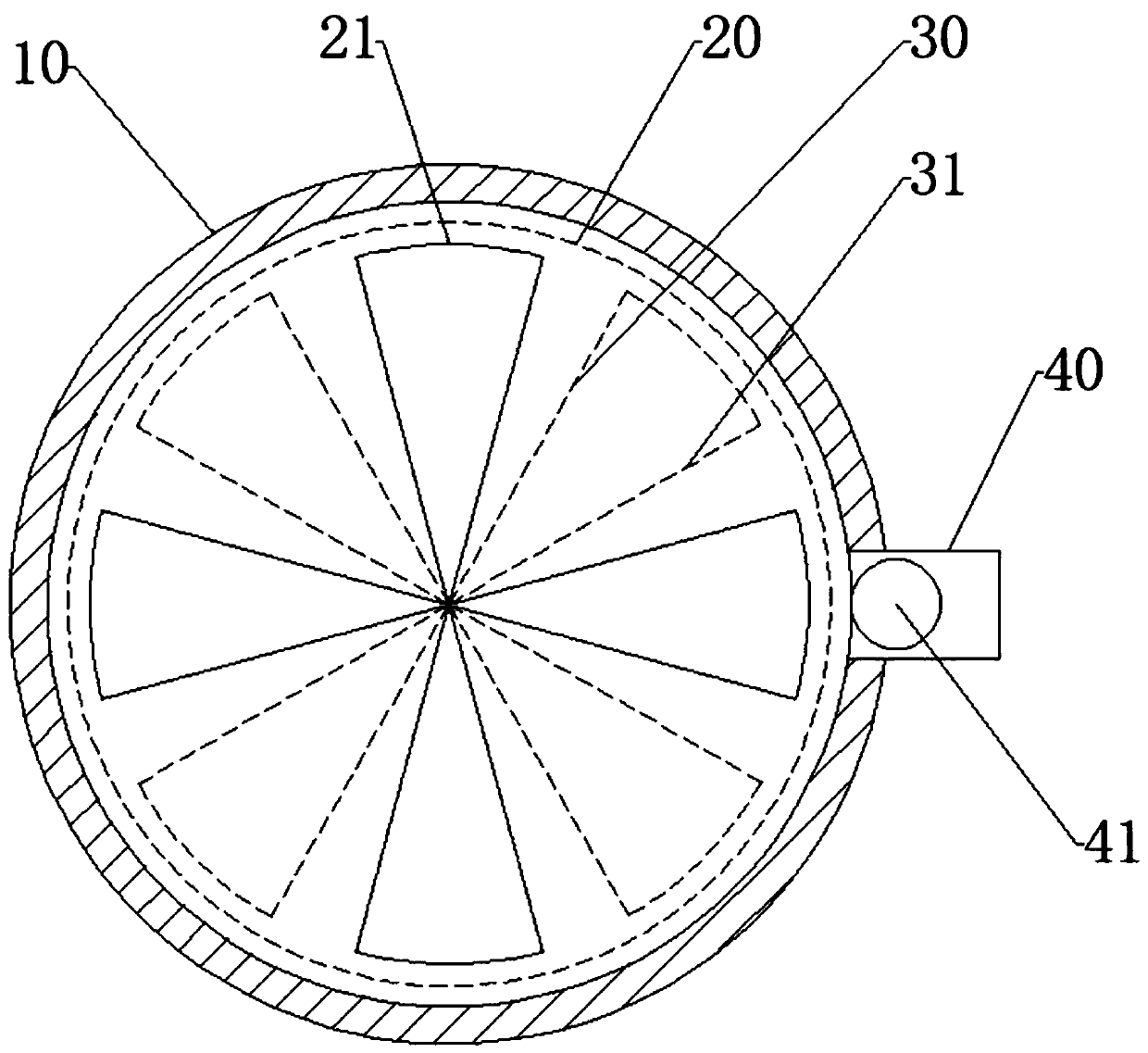

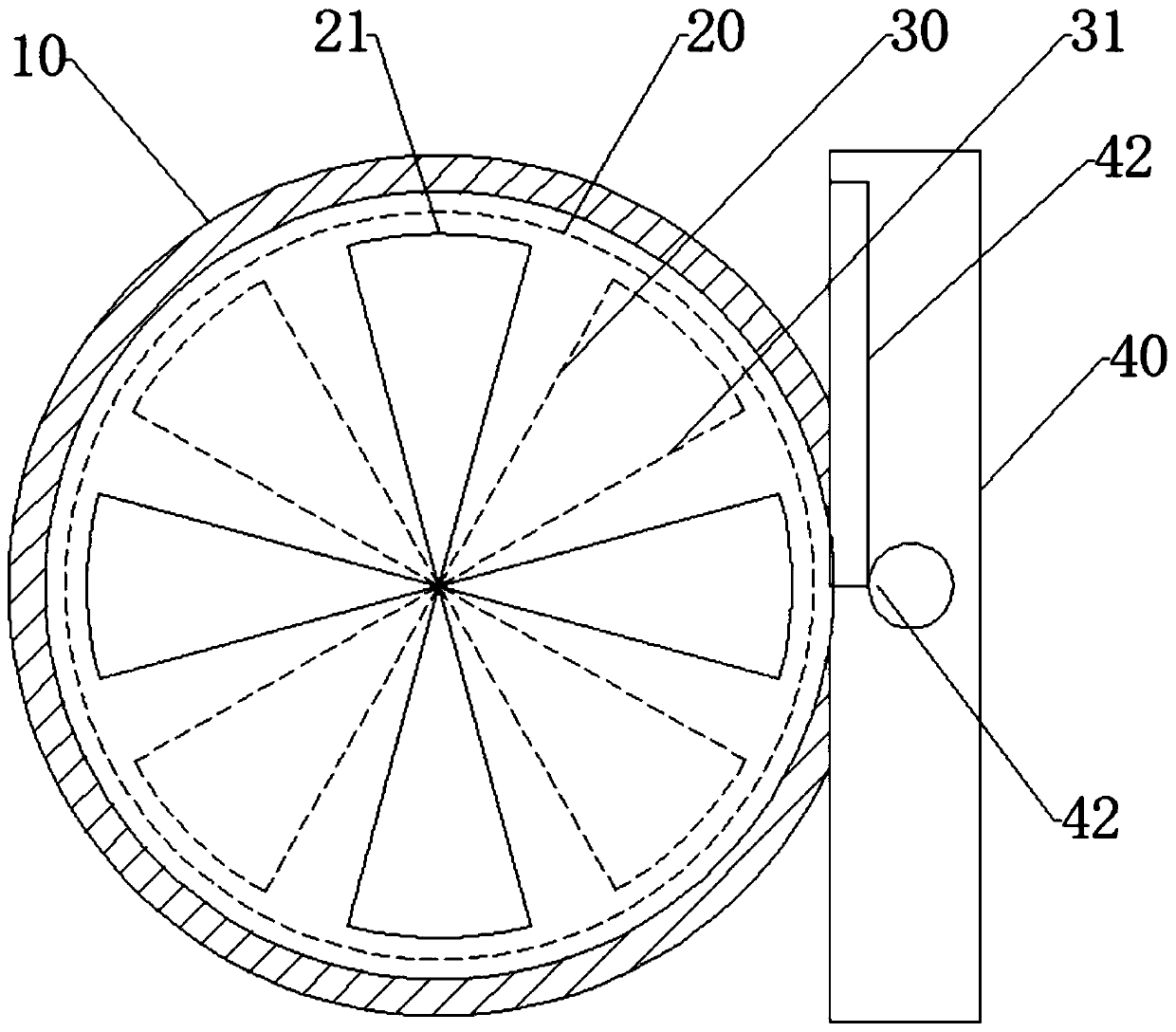

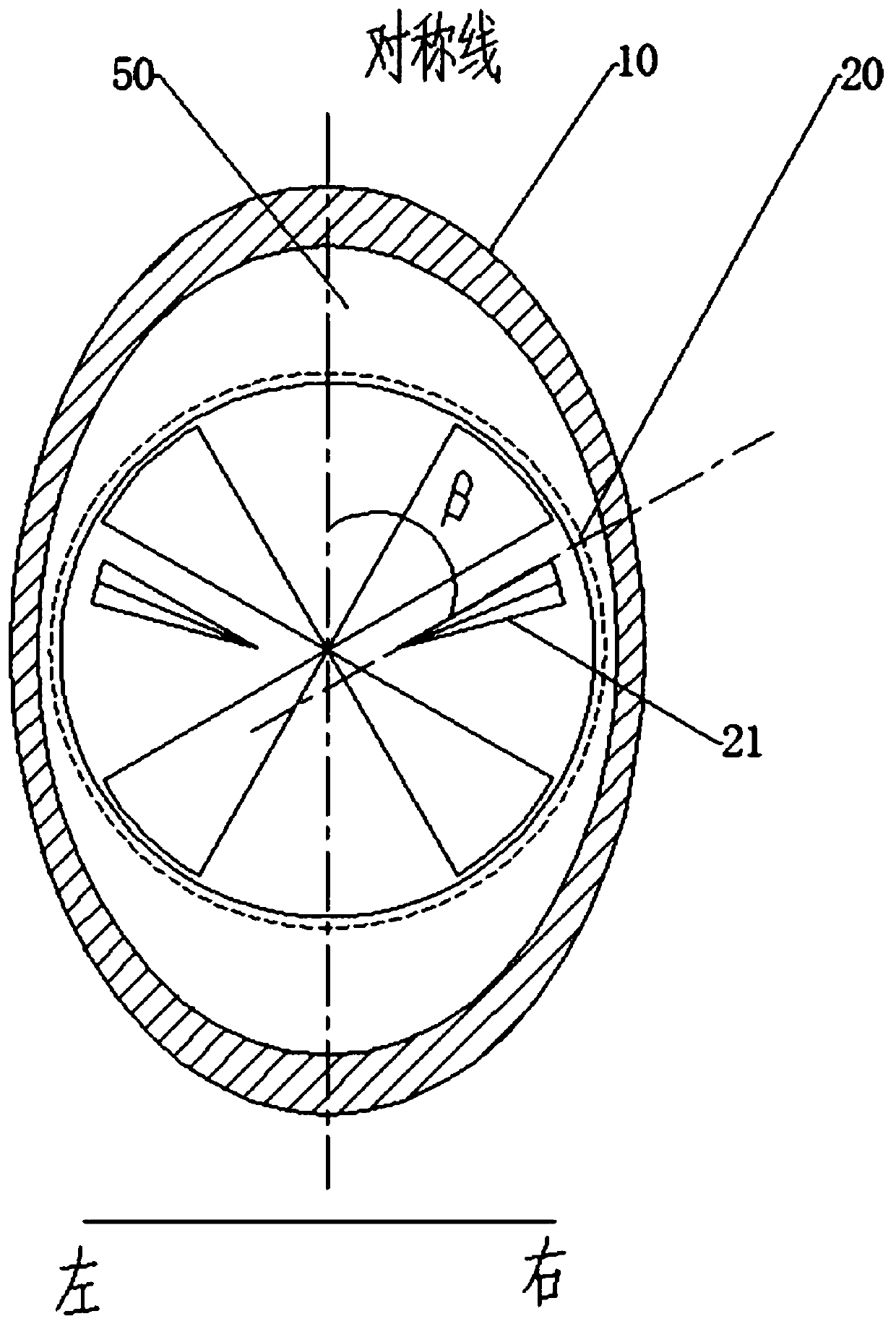

[0018] An atomizer intake pipe adjustment assembly for gas atomized metal powder production, including a rotating plate 20 and a fixed plate 30, the periphery of the rotating plate 20 is embedded in the annular groove of the pipeline 10, the fixed plate 30 is parallel to the rotating plate 20, and the rotating plate 20 Fit with the fixed plate 30 or leave a gap of 0.5-1mm between them. There are ventilation holes 21 on the rotating plate and fixed plate ventilation holes 31 on the fixed plate 30. By rotating the rotating plate, the ventilation holes 21 and the fixed plate can be connected. The vent holes 31 can coincide to vent the duct 10 or be completely offset to close the duct 10 .

[0019] Ventilation hole 21 and fixed plate ventilation hole 31 shape are preferably fan-shaped, are convenient to ventilate like this, and other shapes such as circle, ellipse also can certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com