A-pillar display fixing structure and installation method thereof

A fixed structure and display technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problems of affecting the field of vision, hidden dangers, poor fixed installation, etc., to reduce hidden dangers, facilitate installation and maintenance, Easy to install and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

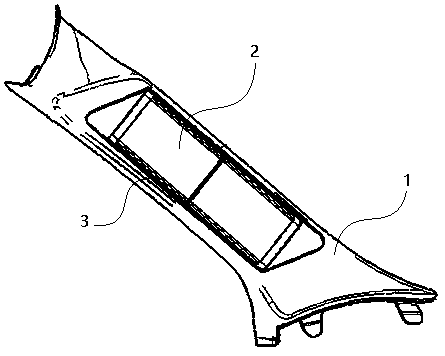

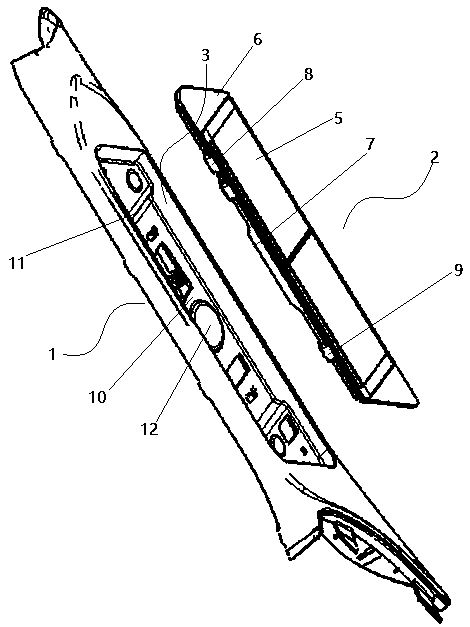

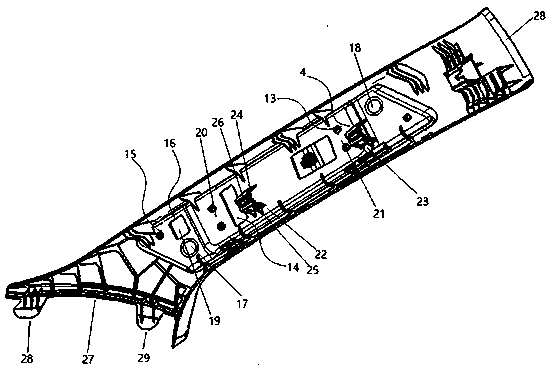

[0028] An A-pillar display fixing structure, comprising an A-pillar guard plate 1 and a display assembly 2, a display mounting groove 3 is arranged in the A-pillar guard plate 1, the display assembly 2 is fixedly installed in the display mounting groove 3, and the display assembly 2. It is installed in the display installation groove 3 by screws. The installation and fixing method is simple, which is convenient for installation and maintenance, reduces production and installation costs, and the installation is more firm, reducing potential safety hazards. The wiring fixing seat 4 of the display assembly wiring is used to fix the wiring of the display assembly through the wiring fixing seat 4, so that the wiring of the display assembly is more tidy in the A-pillar guard plate 1, which is convenient for sorting out the wiring and improves the efficiency of troubleshooting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com