Anti-washaway self-locking manhole cover structure

A manhole cover and self-locking technology is applied in the field of anti-flushing self-locking manhole cover structure and manhole cover structure, which can solve the problems of exposed manhole head, cumbersome maintenance work, large drainage load, etc. , Simple and convenient installation and disassembly, and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

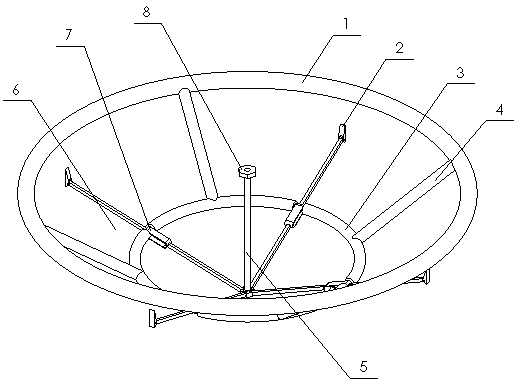

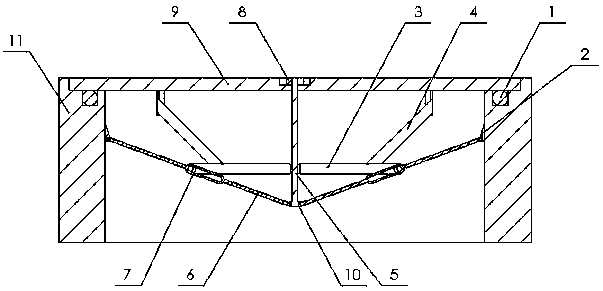

[0017] An anti-washout self-locking type inspection well cover structure of the present invention is realized in the following way: a kind of anti-washout self-locking type inspection well cover structure of the present invention consists of a fixed frame (1), a support angle (2), a support frame (3), Connecting rod (4), slide rod (5), support rod (6), support sliding sleeve (7), fixed nut (8), manhole cover main body (9) and limit cap (10), the limit cap ( 10) The screw connection is placed on one end of the sliding rod (5), and one end of multiple support rods (6) is placed on the outer wall of the limit cap (10) at an equal angle, and the other end of the support rods (6) extends obliquely upward , a plurality of straight legs are hinged one by one and placed on the other end of a plurality of support rods (6), the surface of the support angle (2) is provided with an anti-slip pad, and the anti-slip pad is provided with an anti-slip protrusion. The middle section of the sup...

Embodiment 2

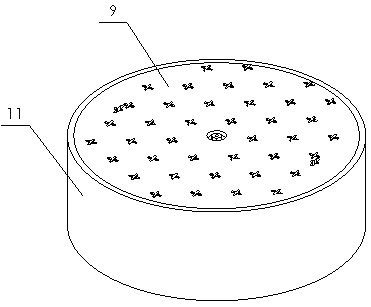

[0022] The difference between this embodiment and Embodiment 1 is: the main body of the manhole cover (9) is provided with a cross-shaped auxiliary bracket (12), and the auxiliary bracket (12) is connected with the fixing nut (8); When in use, it can increase the stressed area of the sliding rod (5) when the inspection shaft cover is pushed up, increase the tension force of the support angle (2), and prevent the sliding rod (5) and the main body of the inspection shaft cover (9) from falling off;

[0023] The surface of the support angle (2) is provided with an anti-slip pad, and the anti-slip pad is provided with a design of anti-slip protrusions, which can increase the friction between the support angle (2) and the side wall of the inspection shaft, prevent slipping, and improve the supporting effect;

[0024] There is an annular groove on the supporting frame (3) corresponding to the position of the supporting sliding sleeve (7), and the design of the supporting sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com