Rapid recharging method based on fusion of laser radar and infrared sensor

An infrared sensor and lidar technology, which is used in instruments, transportation and packaging, two-dimensional position/channel control, etc., can solve the problem of low charging base efficiency, low use cost, and it is difficult for lidar to achieve precise docking between robots and charging bases. and other problems to achieve the effect of improving the recharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

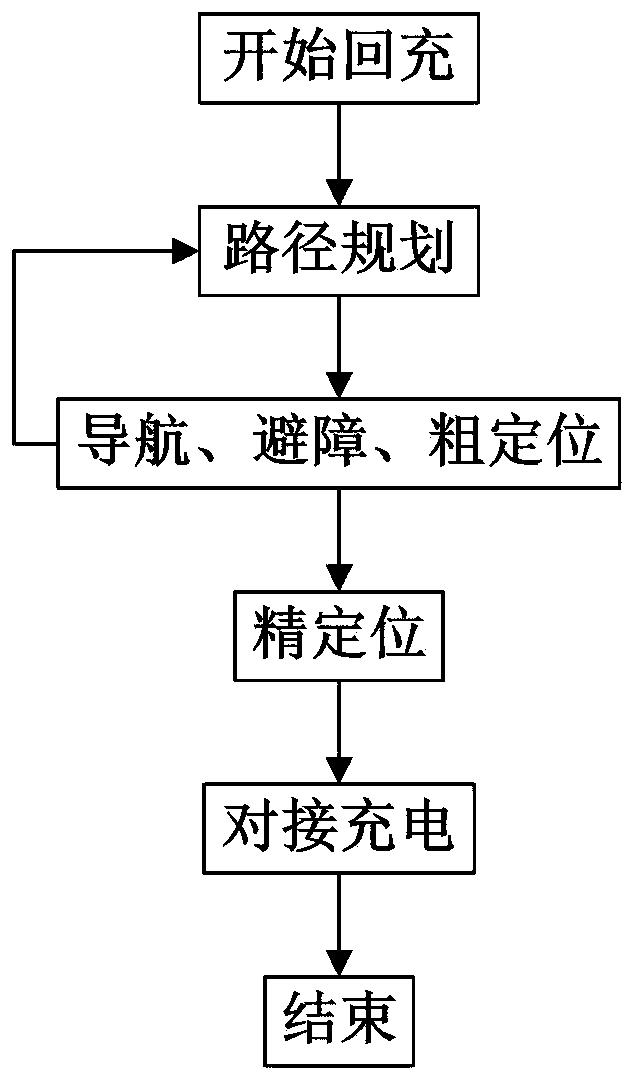

[0031] A fast recharging method based on lidar and infrared sensor fusion, applied to the movement process of the robot automatically docking to the charging stand, including:

[0032] The robot moves to the vicinity of the charging stand according to the scanning result of the charging stand by the laser radar set on it;

[0033] The infrared receiver provided on the robot is turned on, and the robot moves to the charging base under the guidance of the infrared receiver, and the robot is completed by docking the infrared receiver and the infrared emitter on the charging base. Accurate docking with said charging stand.

[0034] In the above scheme, the combination of the laser radar and the infrared sensor installed on the robot realizes that the robot can quickly move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com