Garage fire hydrant mounting structure

An installation structure and fire hydrant technology, applied in fire rescue and other directions, can solve the problems of fire hydrant box collision, reduce the effective area and loss of parking spaces, etc., and achieve the possible effects of increasing parking space and reducing vehicles accidentally hitting the fire hydrant box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

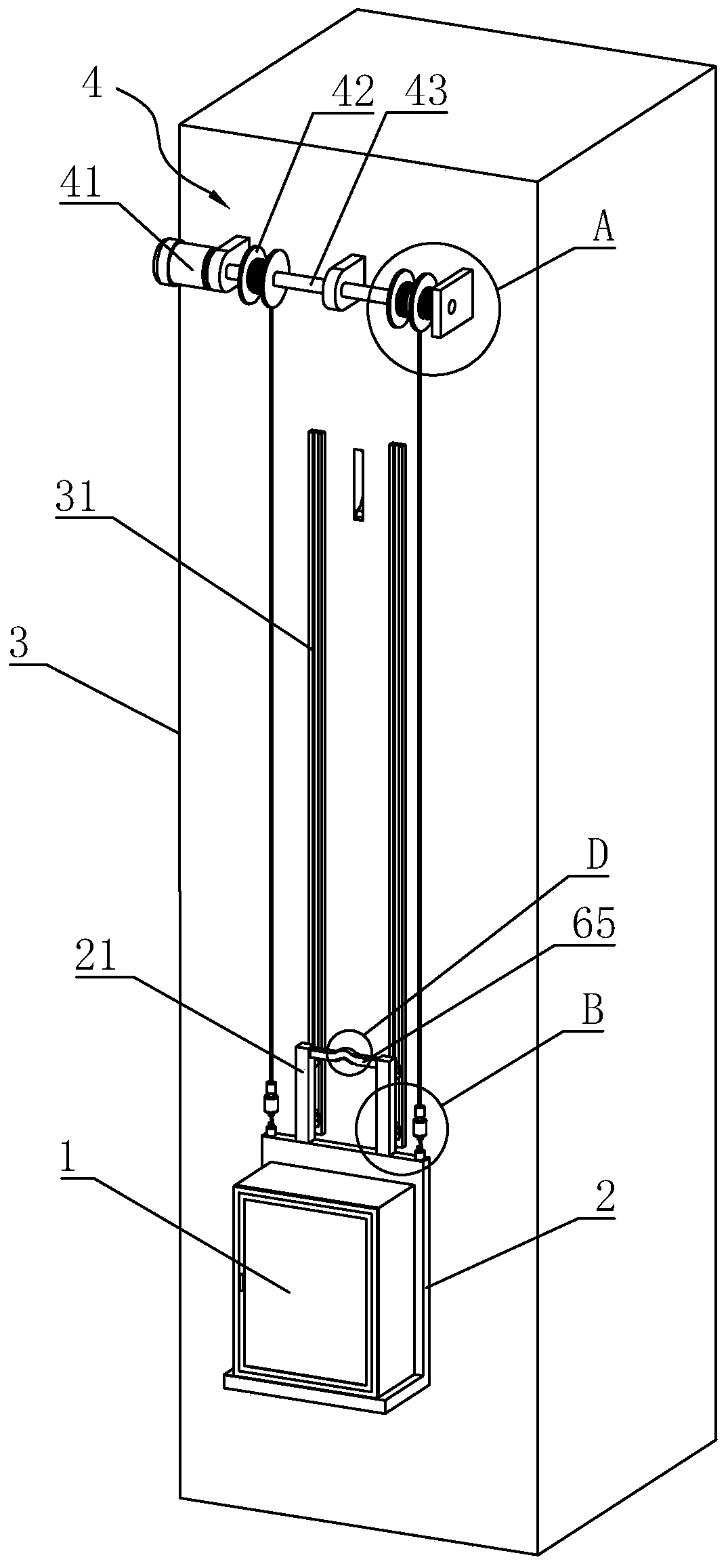

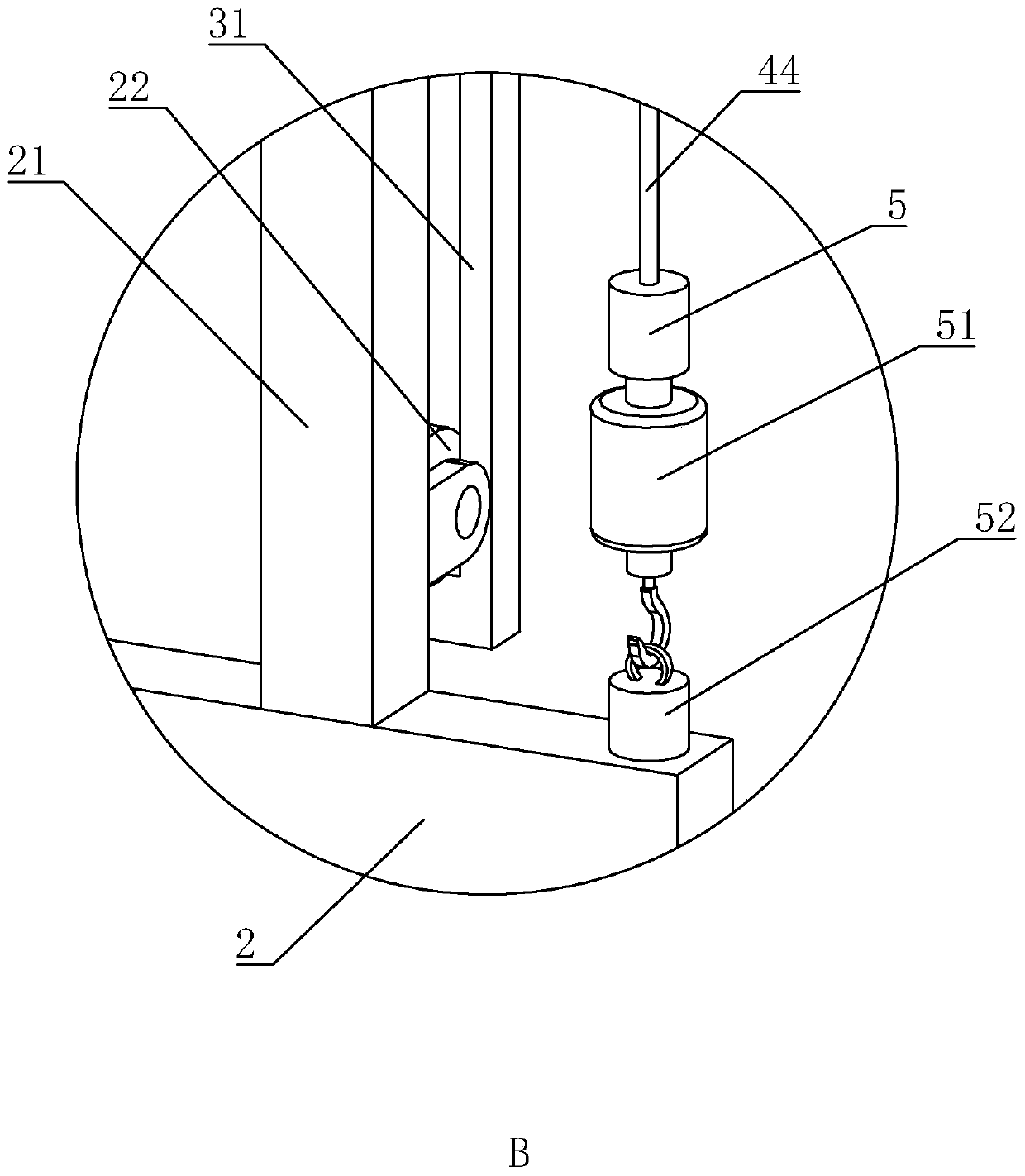

[0040] Embodiment: a kind of garage fire hydrant installation structure, as figure 1 , including a fire hydrant box 1, an L-shaped bearing plate 2, a structural column 3, and a driving member 4 for driving the bearing plate 2 to move along the vertical direction of the structural column 3. The fire hydrant box 1 is placed on the horizontal edge of the bearing plate 2, and the rear part of the fire hydrant box 1 fits the vertical edge of the load plate 2, and the bottom of the fire hydrant box 1 is fixed on the bearing plate 2 by bolts to prevent the fire hydrant box from 1 comes off the carrier plate 2.

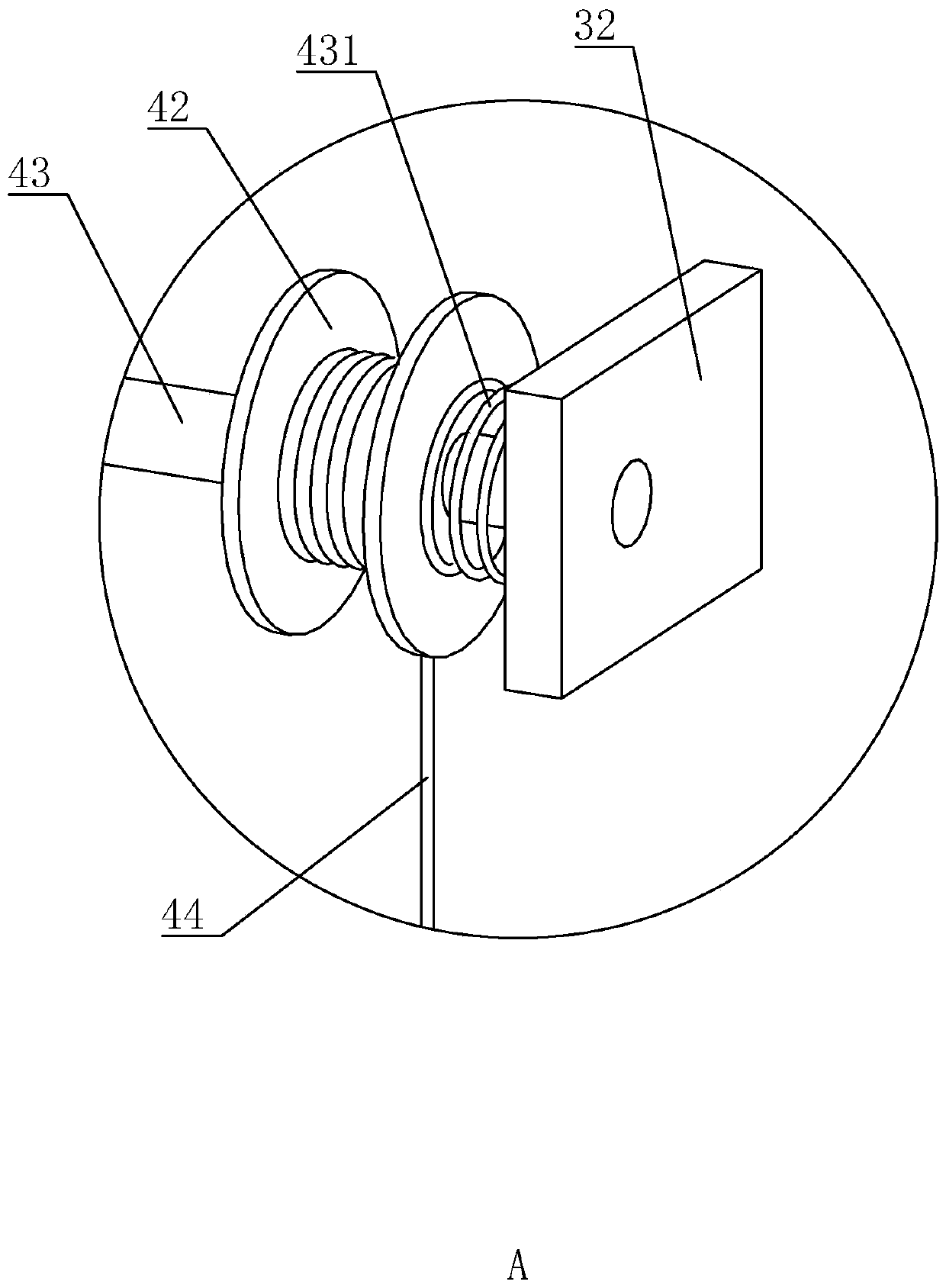

[0041] Such as figure 1 with figure 2 , the driver 4 includes a drive motor 41 fixedly connected to the top of the structural column 3, the output end of the drive motor 41 is fixed with a fixed shaft 43, and the fixed shaft 43 is provided with two winding wheels 42, each winding wheel 42 There are lifting wires 44 wound around them.

[0042] Such as figure 2 with im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com