Load-bearing device for metal-free frame mechanical garage auto-mobile bearing disk

A technology of a load-bearing device and a mechanical garage, which is applied to buildings, building types, buildings and other directions where cars are parked, can solve the problems of complex structure of metal frame garages, not simple enough garages, beautiful appearance, poor safety and reliability, etc., and achieve economical savings. Infrastructure cost and operation cost, increase the effective use area, and the effect of high parking safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

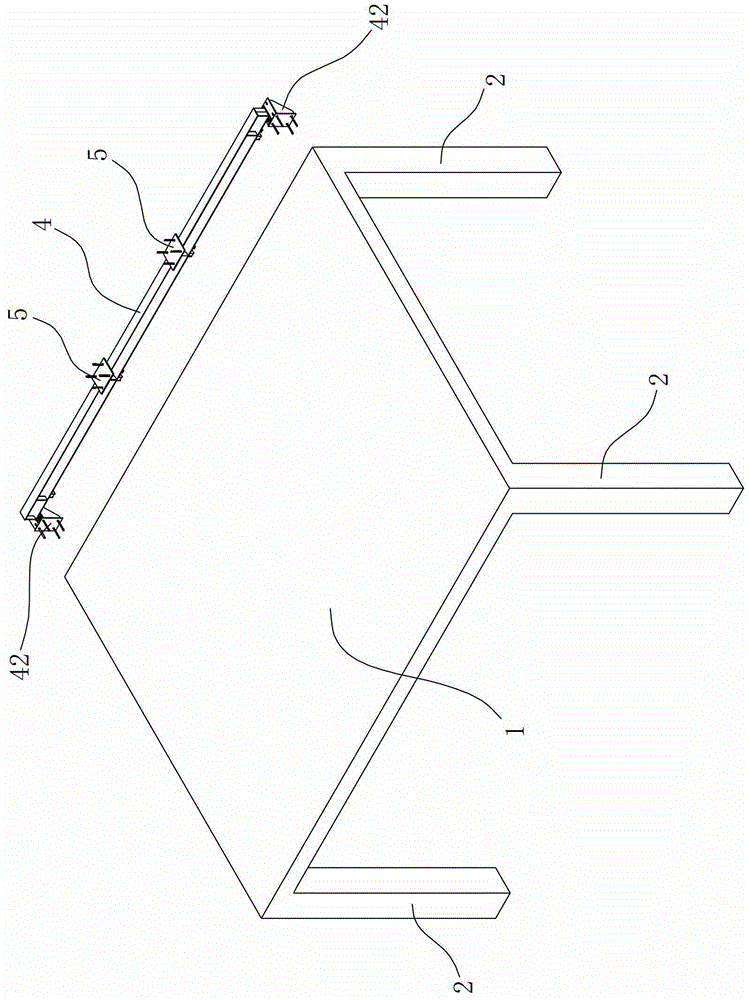

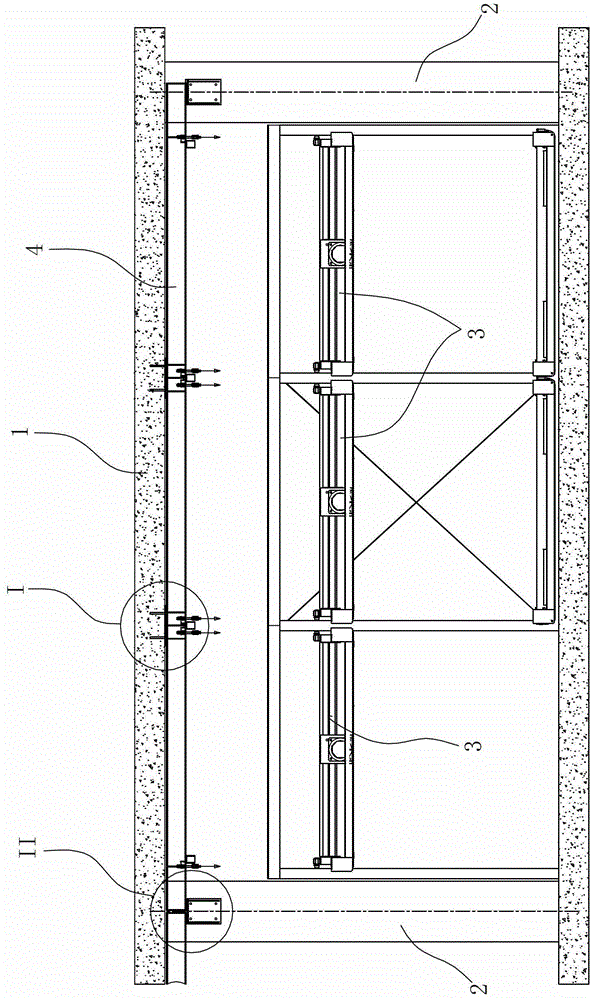

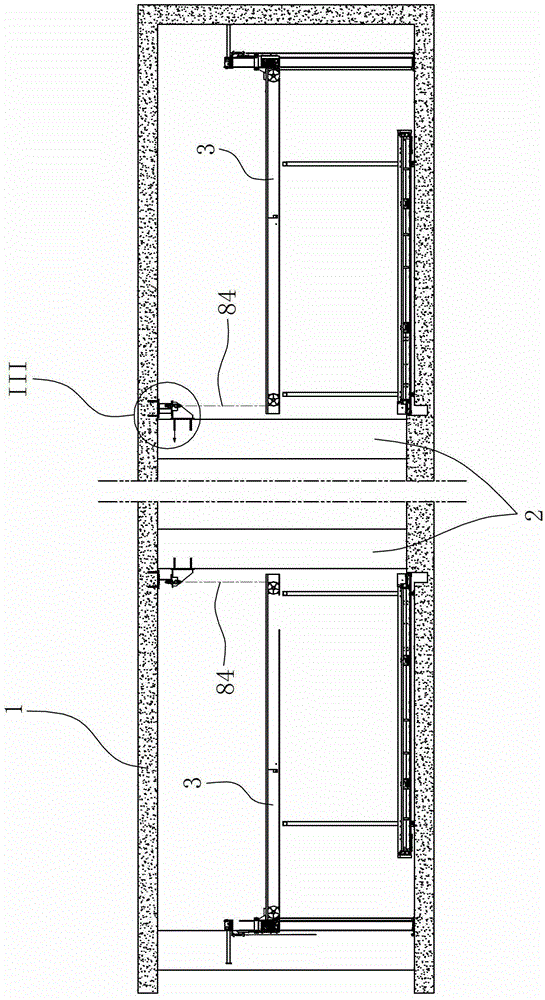

[0031] Such as Figure 1 to Figure 9 As shown, the present embodiment is a load-bearing device of a suspended vehicle-carrying tray 3. This suspended vehicle-carrying tray 3 is mainly used in a garage without a column-beam structure, and the load-bearing device is installed on the building frame of the garage. See figure 1 Wherein, the building frame of the post-beam garage includes a cement building roof 1, and the four corners of the building roof 1 are respectively provided with building columns 2, and the two adjacent building columns 2 arranged along the length direction of the building roof 1 are suspended between two adjacent building columns 2. Wheel 3.

[0032]The load-bearing device of this embodiment includes a steel beam 4 and support feet 42 supported at both ends of the steel beam 4, wherein the steel beam 4 adopts an H-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com